Ceresit grout for tile joints

The company's products Ceresit is in great demand in our country, and therefore is available in all building and hardware stores. Ceresit - a manufacturer with more than a century of history, from the end of the last century, which is part of the corporation Henkel. The company became world famous due to the highest quality of its products and its large market coverage. Among other things, Ceresit produces construction compounds for grouting tile joints.

To date, six types of grout have been developed for different tile materials and conditions of use. To understand all the variety of choice, learn about the methods of working with grout Ceresit, as well as get an objective opinion about the products of the company will help you in this article.

Advantages of

- The possibility of choosing the necessary type of grout from several types, offered by the manufacturer. On sale are grout for ceramic tiles, mosaics, artificial stone and other facing materials.

- The type of grout can be chosen not only on the basis of the material of the facing, but also taking into account the operating conditions. For example, Ceresit produces grout for rooms with a high degree of humidity, exterior walls, swimming pools, production facilities, etc.

- Another important parameter that can be used as a guide when choosing a grout from Ceresit is the width of the joint. The manufacturer produces grout for joints with a width of >5 to 30 mm.

- Also, the manufacturer's range of grout is designed specifically for use at very high or very low temperatures.

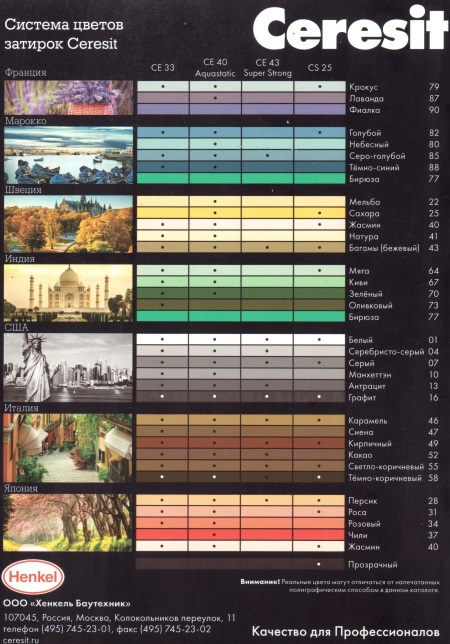

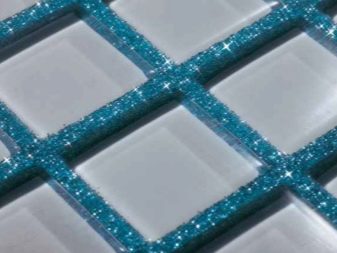

- Another indisputable advantage of Ceresit trowels is a rich color palette. You can choose the right color for any type of tile: monochrome, multicolored or decorated with a pattern.

- Craftsmen-turners note the good wear resistance of Ceresit grout.

Disadvantages

- Many of those who have used Ceresit grout, noted one peculiarity: after drying, the color of the material changes and sometimes it differs significantly from that indicated on the package. Therefore, it is better to buy the grout in a store where you can test a sample.

- The manufacturer packs some types of Ceresit grout in paper bags. If all conditions for storage and transportation are met, the packaging does not matter, but sellers do not always comply with these conditions. That is why buyers often complain that Ceresit packaging leaks moisture, which negatively affects the quality of the product.

Types

- Ceresit CE 33 Super. It is intended for sealing inter-tile joints with a width of less than 0.5 cm. Can be used for tiling exterior walls. It is best suited for finishing of toilets and kitchen areas and is resistant to low temperatures. It has antibacterial and antifungal properties.

- Ceresit CE 35 Super. Intended for sealing joints between tiles, with a thickness of 0.4 to 1.5 cm. It has water-repellent properties, well withstands the effects of sunlight and precipitation. Suitable for use in swimming pools. This type of Ceresit grout should be chosen if you are working with decorative stone cladding, marble and other similar materials.

- Ceresit CE 43 Super Strong. A high-strength grout designed for grouting tile joints between 0.4 and 2 cm in thickness. It is suitable for use in all conditions, as it is water-resistant and hydrophobic, resistant to sunlight, rainfall and temperature fluctuations. This grout can be used for most facing materials, except for marble and glazed tiles.

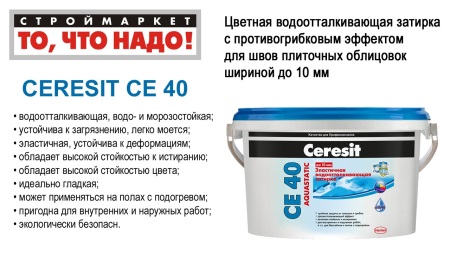

- Ceresit CE 40 Aquastatic. Intended for sealing the joints between tiles up to 1 cm in thickness. It well tolerates high and low temperatures, as well as temperature difference, therefore it is recommended for use in premises with underfloor heating or outdoors. It has dirt- and water-repellent properties.

- Ceresit CS 25. Silicone based grout for sealing tile joints from 0.5 to 3 cm in width. Ideal for use in the bathroom, including for finishing shower cabins. It has good anti-fungal properties. This grout should not be used for kitchen area tiling.

- Ceresit CE 79 UltraPox. Epoxy grout designed for sealing joints of any width. Like all two-component grout mixtures, it is characterized by high resistance to abrasion. Can be used for tiling of exterior and interior walls. Resists chemicals in cleaning agents well.

Take a tile sample with you for an easier shade of grout.

Grout usually has a drying time of approximately 24 hours.

Consumption

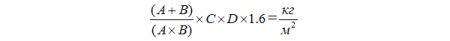

Consumption of grout, regardless of the manufacturer, is calculated using a simple formula:

where, A, B,C - length, width and thickness of the tile, respectively, D - the width of the joint.

Consumption of Ceresit grout also depends on the type of grout mixture. For example, for standard sized ceramic tiles, the consumption of different types of Ceresit grout per square meter is as follows:

|

Tile size, cm |

5х5 |

10х10 |

20х20 |

50х50 |

|

Type of grout |

||||

|

CE 33 (kg) |

0.5 |

0.4 |

- |

- |

|

CE 35 (kg) |

- |

- |

0.4 |

1.2 |

|

CE 40 (kg) |

0.5 |

0.4 |

0.5 |

0.2 |

|

CE 43 (kg) |

- |

- |

- |

- |

|

CE 79 (kg) |

1.3 |

1.0 |

1.3 |

- |

|

CS25 (ml) |

25 |

100 |

- |

- |

Instructions for use

Besides cement grout for tiles, Ceresit also produces epoxy and silicone grout. While the rules for handling ordinary grout are known even to novice craftsmen, not everyone is familiar with the use of new types of grout.

Epoxy

Epoxy grout is very important to mix correctly. In a package with epoxy grout from Ceresit contains two active components, which should be combined, carefully observing the proportions. The grout is mixed with a mixer at high speed.

It is important to remember that after 1.5 hours of mixing, the mixture begins to harden, so epoxy grout should be prepared in small portions.

Seams should be filled with an ordinary rubber trowel. The order of work here is the same as with cement grout, but it is necessary to remove excess grout from the tiles in time. Epoxy grout can be removed only with a special sponge soaked in water (in this case, be careful that water does not get on the unfilled joints, as to work with epoxy grout is only allowed on a dry surface). After the work is done, it is necessary to clean off the "plastic" residue from the grout from the tile. For this purpose, special cleaners are available. Be sure to buy one of them, because it is impossible to get rid of traces of epoxy grout in any other way.

Silicone

Ceresit silicone sealant is sold in cartridges, so it can be applied with a spray gun, which makes the job much easier.

- Before you begin, cover the edges of the tiles with masking tape to protect the coating.

- If the joints between the tiles are very deep, it is recommended to insert a polymer tourniquet in them beforehand.

- Now you need to prepare the cartridge: cut its tip along the thread and fix the tip on it. Then cut the tip so that its diameter corresponds to the width of the seam.

- Fill the grout bottle into the installation gun.

- Fill the seams, remembering to even them out from time to time (you can do this with a finger dipped in soapy water). It is important to have time to touch up the joint no later than 15 minutes after applying the grout.

- You can remove the remains of fresh grout with alcohol or a solvent. And the hardened grout can only be scraped off carefully, taking care not to damage the tiles.

Reviews

Since products of the company Ceresit are actively used not only by craftsmen-finishers, but also ordinary people who make repairs in their own apartments, on specialized forums devoted to construction and repair, are constantly discussed products of this manufacturer.

The most frequent problems that arise during the use of grout from Ceresit:

- The grout does not mix with water, but collects in lumps. Most often this is due to the fact that the craftsman chose to stir the grout by hand. Even with prolonged stirring, you will not be able to achieve the same result as using a mixer. Ceresit grout should only be stirred mechanically.

- Colored grout is washed away with water even days after application. The instructions for Ceresit coloured grouts state that the first contact of the tile joint with water is not possible before 7 days after application. Therefore, the remains of grout from the tiles must be removed very carefully, taking care not to get the joint wet.

- The color of grout from different packages may vary by several shades. The hue of the grout mixture depends on many factors. The manufacturer is aware of this feature of his products, so if a large amount of work is planned, it is recommended to buy the entire grout from one batch (the batch number is indicated on the package).