Russian baths - modern technologies and quality

In recent years Russia has been one of the leading manufacturers of sanitary ware. In addition, our designers were able to show their foreign competitors that they are capable of implementing their own creative ideas and have a sophisticated sense of style. Our designs have won prizes at various international exhibitions and are highly valued by the world's leading manufacturers of sanitary equipment. Russian baths today are able to compete on an equal footing with baths of the world's leading brands.

Moreover, baths of domestic manufacturers are cheaper, because their cost does not include transportation costs and customs duties. Let's dwell in detail on what are the advantages of Russian baths compared with foreign counterparts.

Advantages

Production, established in our country, is responsibly organized, so you can not doubt that the products of Russian companies are reliable and durable. Do not forget that domestic technology does not stand still, so the baths made in Russia are made using technologies that are not inferior to the leading world leaders, and fully meet all quality standards.

Domestic sanitary ware is resistant to mechanical stresses and is not afraid of temperature differences, and is fully adapted to the needs of domestic consumers. Consequently, you can forget about the well-established cliché that Russian baths can not compete with foreign competitors. Manufacturers are actively cooperating with European partners, sharing technology and experience. And the quality standards of Russian baths have long reached the level of Europe. Domestic products can be purchased really at a lower price, and the range is not at all losing to foreign products.

Leading brands

Among the manufacturers of reliable and durable cast iron bathtubs there are certain leaders - Novokuznetsk factory "Universal" and Kirov factory, which represent a wide range.

Production of Russian acrylic bathtubs is constantly developing and increasing. With increasing demand from the population, the number of manufacturers is beginning to increase, and competition between them is getting tougher.

Among the leaders in the production of acrylic baths are the companies "1Marka", "Bas", "Triton", "Radomir" and others. Brands guarantee high quality of products, and the design and shape of baths from these manufacturers can easily compete with the products of companies with worldwide reputation.

Next, let's take a little closer look at some of the leading manufacturers.

1Marka

If we talk about this manufacturer, then you can confidently state that only 100% acrylic is used in the manufacture of baths. Moreover, the thickness of acrylic sheet is 4-6 mm, which fully complies with international standards.

Unscrupulous manufacturers usually make a thin acrylic coating, half a centimeter thick, and then there are layers of not the highest quality material. And, of course, with any scratch or mechanical damage, it is almost impossible to restore the bathtub, and its attractive appearance somehow immediately loses, because its surface becomes uneven. You can have no doubt in the products of this brand.

"1Marka" is responsible for its quality and does not produce cheap baths. Among other things, the company considers every detail, for example:

- structural elements are coated with zinc;

- there are additional fasteners that increase the reliability of the design of the tub;

- the depth corresponds to all standards and consumer requirements for comfort.

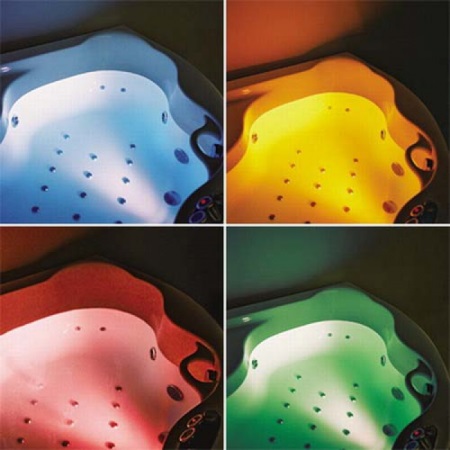

The process of exploitation of such baths is a pleasure. It is noteworthy that, if requested by the customer, the manufacturer can supplement the bathtub with hydro and aero-massage systems, aromatherapy, illumination, etc.

In addition to baths, the brand also produces shower cabins and other sanitary equipment. "1Marka" uses in the production of bathtubs materials supplied from Europe. All factories of the company have a modern multilevel inspection system.

Bas

Russian manufacturer is able to provide acrylic baths for any wallet.

The optimal option for the middle class is made by the company "Bas". But the quality is still determined by strict norms, which the products of the brand meet all parameters. In addition, the company "Bas" appeared on the market in 2000 and during this time has won love and trust of consumers.

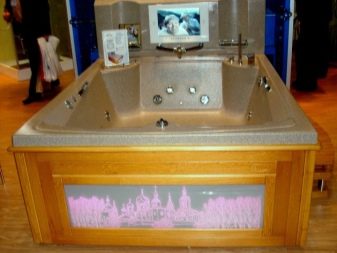

Baths with hydro and aero-massage systems are available for sale. The entire manufacturing process is based on the use of modern Italian equipment and high-quality acrylic. The company "Bas" manufactures not only the bathtubs themselves, but also the bathtub screens, which can be purchased as a set.

Not just acrylic is used in the production, but a polymer plastic consisting of many layers. It was developed by an Austrian company.

This plastic allows to withstand significant loads. Plus, this polymer plastic creates a kind of antibacterial layer of protection, which will save the consumer from having to polish the tub every day. The bottom of the tubs is reinforced, and structures have a reinforced frame with plugs. And most important! Knowing the peculiarities of bathrooms in Russia, "Bas" took into account the fact that in many apartments large baths simply will not fit, so I was able to offer a compact-sized bath.

We advise you to read: Bas bathtubs.

Akrilan .

As soon as the company appeared on the market, it was able to gain a leading position and confidence of customers. The company is constantly expanding its range, increasing production capacity. Mainly shower enclosures and acrylic baths are produced under this brand.

Among the materials used in production, not only European, but also advanced domestic developments are used. The company successfully adapts them to its own production, ensuring the high quality of products. This fact was confirmed by ROSTEST, which awarded "Akrilan" a gold certificate of quality. What is the conclusion? The company is constantly studying the market, taking into account the changing tastes of consumers and produces products that meet all possible quality requirements. And this is quite a high rate.

Aquanet

This manufacturer produces lines of baths, shower cabins and other bathroom furniture. The company provides a wide range of sizes and prices in consideration for all categories of consumers.

"Aquanet" uses in the manufacture of bathroom furniture moisture-resistant materials MDF and fiberboard from the Finnish manufacturer. The coating of materials includes a layer of special primer, which contributes to a more even surface and a high level of protection against damp environments.

For Aquanet, quality is always paramount. That is why painting is carried out in accordance with European standards. Italian paint is used, while the equipment used in the painting process came from France.

Aquatek

The company has established an excellent reputation in the Russian market since 2001. At this stage, "Aquatek" continues to develop actively.

Its main activity is the production of acrylic baths, whirlpool baths and shower cabins. The company values its staff, so each employee periodically passes courses of training, and accordingly, has a huge stock of experience and knowledge.

Moreover, "Aquatek" fully complies with production technology, using materials and equipment from European manufacturers. The quality control system has a multi-level structure, which guarantees the production of excellent products.

Of course, in the production process complies with all safety requirements. The company also has all the necessary certificates of conformity. "Aquatek" takes into account the interests of consumers and tries to meet all the requirements for baths.

Radomir

The company produces acrylic and whirlpool baths, as well as showers. For more than 15 years "Radomir" has successfully established itself on the market and is one of the samples of quality, taking a leading position in the production of whirlpool baths.

The company has been repeatedly awarded with certificates and diplomas, testifying to the indisputable quality of its products. The manufacturer claims that their bathtubs are capable of operating for at least 20 years, and consumers can test this in practice.

"Radomir" introduces innovative technologies into its production process, as well as uses time-tested and proven components.

Whirlpool baths of this manufacturer have a rather low noise and vibration level. Moreover, baths are equipped with feet that can stand even on an uneven floor. Of course, "Radomir" has rather strict requirements for the quality of its products, carrying out control at all stages of the manufacture of baths, including testing of the finished product.

Kirov factory

This brand has become famous not only in Russia, but also abroad. And all due to the high quality of its cast iron bathtubs.

The roots of the company go back to the distant 1745. And although the direction of activity has changed slightly, but the basic principles have survived until today.

In 2006 the Kirov factory completely replaced the equipment, giving preference to German manufacturers of materials and components. All finished products have a perfectly smooth surface.

At the same time, it was Kirov factory specialists who created the technology that began to produce enamel with silver ions and subsequently patented it. Due to this, the manufacturer has improved the hygienic requirements of the finished products. Kirov factory produces a fairly large number of models with different shapes, sizes and even accessories.

Triton .

The brand entered the market in 2002, immediately aiming at production with the use of the highest technology. Actually, that is why "Triton" is not stingy with the latest equipment, due to which the finished products have the highest level of quality.

Acrylic sheets from the best and proven suppliers are used in production. In this case, from the beginning of its creation to the end of the bathtub undergo more than one stage of the production cycle to ensure that the final product does not have a single flaw. "Triton" has exclusive equipment for applying a reinforcing layer on the tubs, which distinguishes the company from others like it.

In this case, finished products are sold at prices affordable to different categories of consumers, without focusing on specific segments of the population.

More about materials and sizes

Russian manufacturers often use steel, cast iron and acrylic to create bathtubs.

- Cast iron is good because it allows you to retain heat for a long time and prevents corrosion. Of course, cast iron baths are quite heavy, but they eliminate any vibrations and are easy enough to install. In addition, cast iron is durable. Finished product can easily stand for more than a quarter of a century. And with modern technical equipment it is possible to produce baths of different shapes and sizes.

- Acrylic bathtubs are unpretentious and long-lasting. They keep heat well enough and are pleasant to the touch. They can be easily polished at home, and the variety of modern acrylic baths will allow you to choose exactly what is required for your bathroom. It also plays a role that acrylic baths are easy enough to install and do not require constant washing with special means. However, acrylic is not resistant to scratches, which is a disadvantage.

- Bathtubs made of steel, Have a high level of hygiene and at the same time heats up instantly. At the same time, the low weight allows for trouble-free installation of the tub. Due to the greater plasticity of steel compared to cast iron, manufacturers offer a wider range of steel baths. However, the heat retention of such baths is not very good, and the noise from the water is heard much louder.

As for sizes, manufacturers use the most common in Russia:

- 150х70;

- 170х70;

- 170х75;

- 170х80.

However, everything is not limited to that. There are bathtubs with both smaller and larger dimensions.

The possibility of additional technical equipment

Most manufacturers offer the optional installation of whirlpool systems on the bath. Most often, this option is characteristic of acrylic bathtubs.

We can speak not only about whirlpool, but also about aero-massage equipment. As a rule, any manufacturer has additional equipment that they design by themselves and build into the bathtub if the buyer wishes.

Joint ventures

Domestic manufacturers are happy to share experience with foreign colleagues, so there are companies that operate not only in Russia, but also abroad. We are talking about joint production of bathtubs. Or leading European manufacturers cooperate with our companies, which use their materials and technologies.

For example, for the production of baths of "1Marka" company hydro-massage equipment of a well-known Italian company is used.

Also, Russian company "DoctorJet" uses Italian equipment in the production of baths. And here firm "Victoria", being one of the big Russian suppliers of sanitary ware, has its manufacture in China, and gives a big choice of equipment for bathrooms.

Leaders in sales

Among the manufacturers of acrylic bathtubs, some of the well-deserved leaders are companies:

- "1Marka",

- "Bas",

- "Triton",

- "Radomir".

These manufacturers have long been successfully established in the market and are not going to give up their positions. Among the leaders in the quality of cast-iron bathtubs, it is clearly worth noting the Kirov factory, which has maintained its tradition of quality for decades, as well as the factory "Universal", located in Novokuznetsk.

I have a bathtub assembled in Russia. We have been using it for 5 years now and we are happy with it. No problems.