Design and operation of automatic washing machine

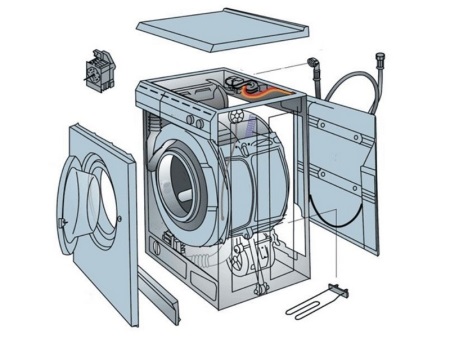

Regardless of the brand of automatic washing machines, the device of models with front-loading is almost identical in different manufacturers. Understand the device of such equipment should any owner. This will help to understand how the automatic machine works, what could fail at different problems, as well as whether you can cope with the breakage with your own hands.

The main nodes of the automatic machine include:

- Body;

- Tank;

- Drum;

- The system of water intake;

- Pressostat;

- Electric motor;

- HEATING ELEMENT;

- Drainage system;

- Control box.

Housing

All elements of the washing machine, regardless of the brand - Indesit, LG, Samsung, Ariston, Electrolux, Bosch or another, are located inside its metal housing. In the case there is a base, the front panel with a hatch, the top cover, the side walls, and the back wall.

In the upper part of the front wall of the housing there is a control panel, and in the left corner there is a container for loading detergent (dispenser). Usually there are 3 compartments in this container (two for powder and one for liquid detergent), but there may be more or less depending on the model (from 1 to 5). The powder loaded in the dispenser falls into the tank through one or more nozzles by the water jet.

In the center of the front wall is the hatch of the washing machine. There are parts such as the rubber door cuff and the device responsible for locking the door during washing. Inside, the cuff is attached to the tank by means of a clamp. Thanks to the locking device, the door can not be opened during the washing process. Most often in such a device there is a thermocell, so after the end of the washing the door remains closed for a while.

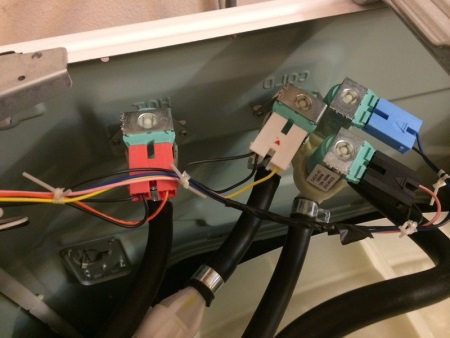

Water intake system

The signal to fill water comes from the control module to the solenoid valve, to which the hose for filling water is connected. This hose must be connected to the water supply.

Tank and drum

The tank is considered the main and most voluminous element of the automatic machine. It can hold 35-60 liters of water. To avoid excessive vibration during washing, the tank is not rigidly connected to the body. To support it, there are two or four springs in the upper part of the machine, and two or four shock absorbers in the lower part. In addition, to avoid imbalance and strong vibration of the tank during washing, concrete counterweights are attached to it. Thanks to this design, the body during the operation of the technique, despite the vibration of the tank, remains stationary.

Inside the tank is a drum, connected by belt drive or direct drive to the motor. The laundry is loaded into the drum, and after starting the washing program the water and detergent start flowing into it through a number of openings. At the front of the tank is connected to the drum by a rubber cuff to ensure tightness, and at the back of the drum shaft passes through the tank to the bearing unit.

The drum is usually made of stainless steel and the tank can be either steel or plastic. The second option is cheaper, but it is more fragile and has a shorter service life. Often the tank has two halves, which are connected by bolts or with a clamp, but in many machines there are non-disassembled tanks.

Drainage system

The main elements of the automatic machine's drainage system are the drain pump and a plastic drainage corrugated hose 1-4 meters long. One part of the hose is attached to the pump with a clamp, and the other is led into the sewer system.

Drainage should normally be performed several times during the laundry. In the structure of the pump, there is a motor, impeller and "volute", to which the hoses are connected. The pump is most often synchronous. The pump operation is controlled by an electronic module.

Since the most frequent failure of the drainage system is the failure of the pump due to its clogging, the device of the machine provides the possibility of easy access to the pump for its regular cleaning. It is recommended that the pump filter be checked and cleaned at least every 6 months.

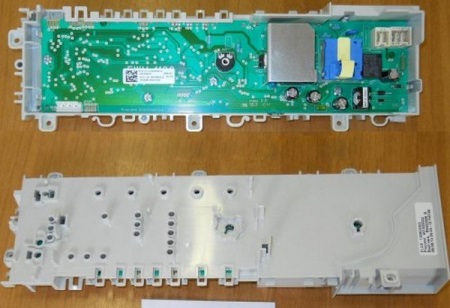

Control unit

This unit of the washing machine commands all other elements, so it can be safely called the "brain" of the machine. It is also called a programmer, an electronic board or a control module. It is from this unit that commands are given to the filling system, the heating element, the drum, the drain pump and other parts.

Control unit is the most complex and expensive part of the washing machine. In its structure there is a digital indicator, thanks to which the user knows everything about the operation of the machine. In most models, in case of malfunction, this indicator begins to show an error code. After knowing its deciphering, you can determine what the essence of the breakdown is, and whether it is possible to cope with it without calling a specialist. If the module itself is out of order, you should contact a specialist to repair or replace it.

Sensors

The operation of the control module is based on the control of various sensors that send information to it about all the processes in the machine during the washing.

Such sensors are:

- Pressostat. This is the name of the sensor, whose function is to monitor the water level. Another its name is the level switch. It can be electronic or mechanical, and the principle of its operation is pneumatic. As soon as the pressostat sends a signal to the control module that there is enough water in the tank, the machine will continue its work.

- Air chamber. This plastic part is located next to the drain spigot and is important for the operation of the pressostat. When the tank fills with water, the air pressure in this chamber increases proportionally with the water pressure. Through a small fitting, the pressure is transferred to the pressostat.

- Thermostat. Such a sensor is located at the bottom of the tank. The main function of this sensor is to determine the water temperature in the tank and transmit the data to the control module.

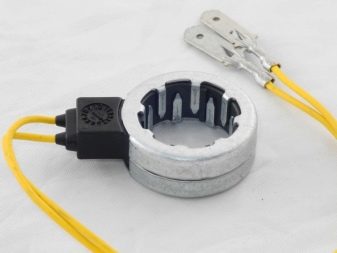

- Tachometer. Its main function is to control the engine speed, which is important for different modes of washing and spinning process.

The heater

Located inside the washing machine, the heating element is responsible for heating water during the washing process. The power of the heater usually ranges from 1800 to 2200 watts. It is located at the bottom of the tank and is considered one of the most vulnerable elements of such equipment. Its failure is one of the most common and most often occurs due to the accumulation of scale on the surface of the heater.

The motor

The main function of the motor in a washing machine is to ensure the rotation of the drum. Most often, the automatic machine has a collector motor, but you can find models with a commutatorless or asynchronous motor.

In models with direct drive, the motor is attached to the drum (to its rear wall). This type of electric motor in the washing machine is called more efficient. Its rotation requires less energy, and the level of vibration and noise from the unit with direct drive will also be less. In addition, such a motor takes up less space, which allows you to create machines with compact dimensions.

Belt-driven models have a pulley that is located at the back of the tank. It is connected to the motor by a drive belt. When turning on the motor starts the movement of the belt, the pulley begins to rotate and thus provides and rotation of the drum. The main disadvantage of such a machine design is the wear of the belt due to the effect of friction. In addition, such a washing machine vibrates during operation more than models with direct drive.

About the structure of the washing machine and its principle of operation is well told in the following video.