Grease for washing machine oil seals

The washing machine is usually purchased with the expectation that it will last at least a dozen years, but this is not always the case. The service life of a washing machine depends on many factors: the conscientiousness of the manufacturer, frequency of use and compliance with the rules of operation.

Careful maintenance includes not only the choice of quality laundry detergents, timely cleaning and prevention of scale formation, but also control of the condition of the internal elements of the washing machine.

One of these elements is the packing. About what it is and how to maintain it in working order, you can learn by reading this article.

What is a stuffing box and why it is lubricated

A packing case (or, as it should be called, a packing device) is a machine part that serves as a sealing element between two of its parts, one of which is moveable, and the other is not. The stuffing box is usually made of rubber, so it not only seals but also seals the joint.

In a washing machine, oil seals are needed to keep water out of the bearings. They are placed on top of the bronze sleeve, which, in turn, is fixed along the half axle. The oil seals must be replaced along with the bearings so that the connection will always remain tight and leak-free.

The axle shaft is the rotating shaft on which the washing machine tank and drum are attached. As it rotates, the shaft makes contact with the inner surface of the gland. Constantly exposed to friction, this part quickly wears out. To slow this process, a special grease for oil seals is used, which ensures sliding, thus reducing friction. If the grease is not renewed in time, the gland will dry out and begin to leak water, leading to bearing failure and malfunctioning of the washing machine.

Lubrication Requirements

There is a category of washing machine owners who, instead of specialized compounds for the care of oil seals, prefer to use folk remedies, such as vegetable oil or grease. This solution is undoubtedly more economical, but it does not affect the condition of the mechanism in the best way.

Therefore, we strongly advise you to use only products that meet the following requirements:

- are waterproof, that is, do not lose their properties in constant contact with water;

- do not have an aggressive chemical composition, which does not destroy the surface of the packing and metal shaft;

- are resistant to temperature fluctuations, do not disintegrate and do not lose their properties when exposed to heat;

- Have enough density and viscosity, so that for a long time is not washed away by water.

Which one is better to use: tips for choosing

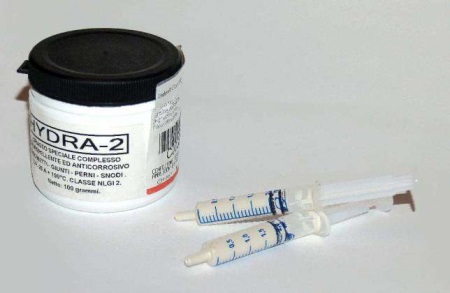

Lubricant for oil seals are usually sold in stores that specialize in the trade of washing machines or spare parts for various types of household appliances. The price of this consumable material may surprise you unpleasantly: this is due to the fact that it is a narrow purpose product, which is quite difficult to find on sale.

Often manufacturers of household appliances are engaged in the production of lubricants for oil seals, which are designed specifically for this brand of washing machines, but in reality are suitable for all models. Most lubricants are interchangeable, you only need to pay attention to the main component of the composition. Silicone and titanium greases are popular, which are good at repelling water and can withstand temperatures up to 200 degrees.

Instructions for use

To replace the packing or renew the grease, you will first have to almost completely disassemble the washing machine, pull out the tank and remove the drum from it. On how to do this, we told in detail in the article "How to remove the bearing from the drum of the washing machine?"

When replacing worn bearings and seals with new ones, we need to make sure they last as long as possible. To do this, we need to properly apply grease to the oil seal. First, apply a thin, even film of grease to the outside surface of the case. Then proceed to the inner surface. The layer should be a little thicker here. After that, the packing can be installed in place.

See the following video to see this entire process in detail.

What can replace the grease?

Sometimes it is not possible to find a special grease for oil seals. In this case, craftsmen replace it with similar oil-based means, such as solidol or lithol. Specialists warn against using these greases, as they contribute to quick wear of oil seals. Such lubricants are used in the automotive industry, but they do more harm than good to household appliances. Therefore, it is better to spend time and money to purchase specialized products that have a lasting effect and are completely safe for washing machines.