Repair of washing machines with their own hands

The washing machine is a common household appliance now found in most apartments and homes. And if it breaks down, it becomes an unpleasant problem that requires an immediate solution.

Calling a master, you can repair the machine rather quickly, but you will have to pay for his work. But sometimes, after understanding the possible causes of the breakdown, it is quite realistic to fix the problem yourself, fixing the technique with your own hands. And to do this, you should learn how washing machines are arranged, how they work, what breakdowns are most common and how you can repair the machine with your own hands.

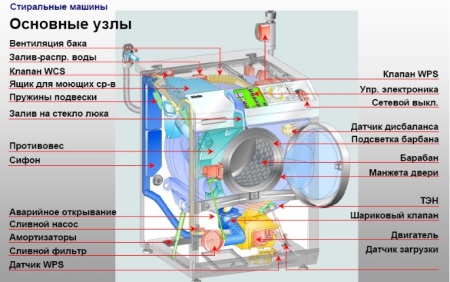

The device

In washing machines there are such nodes:

- The body with a panel for selecting the program;

- Dispenser for detergents;

- Door with latch and seal;

- Tank;

- Electric motor;

- Drum;

- Temperature sensor;

- Heating element;

- Drive belt;

- Water valves;

- Pump;

- Inlet valves;

- Spring Suspension;

- Supply hoses;

- Exhaust hose;

- Adjustable feet;

- Weights for balancing;

- Water level regulator;

- Water collector;

- Drainage riser.

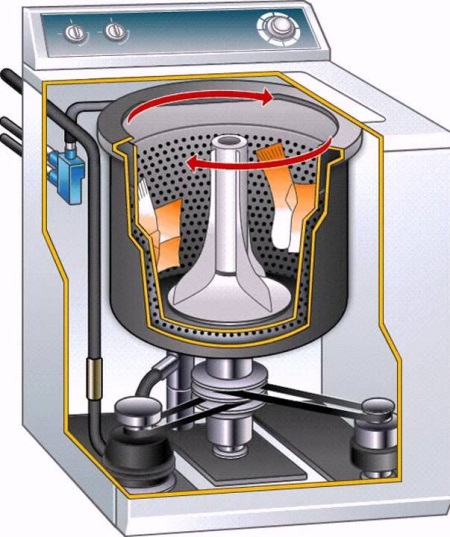

Principle of operation

Practically all devices work according to this principle:

- After opening the inlet valve, the necessary volume of water is poured inside the drum. Once the water is filled to the level determined by the regulator, the valve is closed.

- The water begins to heat up. If there is no temperature sensor, the heating element is switched off by a timer.

- At the same time, the electric motor turns on, as a result of which the drum begins to rotate in both directions, with its turns occurring with different time periods.

- The pump starts pumping dirty water, and then clean water is loaded into the drum.

- After the motor is switched on again, the laundry begins to rinse at low speeds.

- Then the motor is switched off and the water is pumped out again, and then the switched on motor picks up speed and the laundry is wrung.

You can learn about how the washing machine works by watching the following video.

What tools may be needed?

To independently check the serviceability and repair work with such equipment as a washing machine, you should have on hand:

- A flathead screwdriver and a Phillips head screwdriver;

- A service hook;

- Pliers for self-clamping clamps;

- Extended bent pliers;

- Tweezers;

- Phillips head screwdriver; Phillips head screwdriver;

- Pliers;

- Pliers;

- A small flashlight;

- Flat wrenches (8/10 and 18/19).

For the first things to look out for, check out the video with tips from the pros.

It does not turn on

|

The reason |

What to do |

|

Wrong washing program selected |

Check the program selector switch to verify that the pause mode is not activated. |

|

Start button does not work |

Using a tester, check whether the button operates when pressed. If it is defective, replace the button. |

|

Door not closed. |

Make sure that the door of the unit is securely closed. The seal may be obstructed. |

|

The machine is not plugged in or the circuit breaker in the switchboard is broken |

Check that the machine is connected to the mains and that the electricity is supplied to the house. |

|

The plug is defective. |

Disassemble the plug to make sure the contact connections are okay. |

|

Can't get water into the machine |

Look to see if the taps that should supply water to the machine are open. |

|

The wiring inside the machine is faulty |

With the unit unplugged, remove the outer panel, check the terminal clamps (if oxidized, clean them) and test the cord for breaks. |

|

Time relay is broken |

Rotate the program switch until you get the drum to start spinning. This will check the timer and if it is not working, replace it. |

The water is not heated

|

The reason |

What to do |

|

Problem with the water level regulator (the heater does not turn on when the regulator does not respond to fill the drum) |

Check the switch and if it is broken, replace it with a new one. |

|

Heater, heating element is encrusted |

Disassemble the machine, remove the heater and descale it, then put the part back in place and reassemble the machine. |

|

Heater is broken |

Check the condition of the contacts. If oxidation has occurred, use a fine sandpaper to clean them. If the contacts are loose, retighten them. If the problem is not with the contacts, after disconnecting one wire, test the heater for breaks. A burned heater will have to be replaced with a new part. |

|

The thermostat that turns off the heater when the water reaches the desired temperature is not functioning |

Test the thermostat and replace with a new part if necessary. |

The heating element can be replaced at home. On the process of replacing the heating element in the washing machine Ardo, LG with front-loading and tips on buying heating elements see in the video of Vladimir Hotuntsev.

The machine stopped during the washing

|

The Reason |

What to do |

|

Wrong program of the machine |

Inspect the panel, making sure the switch is not on pause. |

|

No power supply |

Using a tester, check the power supply voltage in the socket as well as whether the circuit breaker in the switchboard is disconnected and the plugs are working properly. |

|

The hoses are clogged. |

Check the condition of the inlet hose as well as the outlet hose, and after finding a clog, flush the hoses. |

|

Pump is broken or clogged. |

After removing the pump, inspect the impeller, and if necessary, replace the defective pump. |

|

Inlet Valve Dirty or Broken |

The first step is to clean the valve and if faulty replace the part with a new one. |

|

Drainage of water through the discharge hose (water entering the machine due to siphoning immediately flows out of the machine) |

Check how well the outlet hose is connected to the riser pipe. |

|

The thermostat is broken |

Check whether this part is functioning and replace with a functioning thermostat if necessary. |

|

Heater element is broken |

After checking the electrical circuit, replace the element if necessary. |

|

Programmer timer is not working |

If this part does not work, you will have to replace it with a new timer. |

|

The electric motor is broken |

Remove the drive belt, then turn on the wringer and, after plugging the machine in, check that the motor has started to rotate. The faulty motor must be disassembled, and then check the operation of its elements. |

Pump replacement can be done with your own hands. Vladimir Hotuntsev will tell you about replacing the pump in a Bosch washing machine with a vertical load in the following video.

The drum doesn't rotate

|

The reason |

What to do |

|

Wrong mode |

Check if the selected program is paused. |

|

The drive belt is out of place |

Check the condition of the drive belt (how tight it is) - if you have pressed the belt and it has shifted up to 12 mm, everything is fine. When you find that the belt is not tight enough or has come off, move the electric motor down slightly, tighten the belt (making sure it is not overtightened), then tighten the bolt. If the machine does not have a tensioner, you will have to replace the drive belt with a new one. |

|

The door lock is broken or stuck |

Press the knob several times to make sure the latch is not jammed. If pushing has no effect, then the part is damaged and needs to be repaired. |

You can replace the belt yourself using a video by Vladimir Khatuntsev.

Problems with water

No water coming

|

The Reason |

What to do |

|

Closed valves responsible for water supply |

Open the valves, making sure they have been closed beforehand. |

|

Inlet hose is deformed |

Look at the hose and if it is flattened, you should flush the part and bend it if necessary. |

|

The intake filter is clogged. |

After closing the intake faucet, disconnect the intake hose. Using pliers, remove the filter and then rinse the part under running water. Put the filter and then the intake valve back in place and then connect the intake hose. |

|

Intake valve ruined. |

If the filter is unable to trap dirt, it will get onto the valve and cause it to malfunction. In this case, the valve will need to be replaced. After disconnecting the intake tubes, locate the valve and replace it. |

|

The switch that shuts off the inlet valve after the machine reaches the correct level of water is broken (the tube may be damaged or clogged) |

Check the tube that is attached to the switch - if it has a hardened end, cut it off and reattach the tube to the switch. Blow into the tube to check how the switch works - you should hear a click. Next you need to loosen the clamp on the hose that secures the pressure chamber to the reel. Inspect the chamber and flush it thoroughly until the inlet as well as the outlet is completely clean. Check it for any damage. Verify that the switch is in good working order using a multimeter. If it is broken, replace the part with a new one. |

|

The motor is broken |

Depending on the breakage, it can be repaired or replaced with a new one. |

If the water does not pour into the washing machine, watch the video channel "Washing +".

It is very slow to fill

|

The reason |

What to do |

|

The inlet hose is pinched |

Check the hose and straighten the deformed area. |

|

Inlet hose is clogged. |

Rinse hose until clogged. |

|

Water pressure is insufficient |

Check whether the valve responsible for the water supply is fully open. You may be suffering from low pressure in the mains. If this situation occurs in a detached house, installing a pressure tank in the attic can help. |

Not draining

|

The reason . |

What to do |

|

Wrong programme selected |

Make sure that you have not pressed pause on the machine, and that you have not activated the delayed wash. |

|

The water level switch does not work |

After checking its function, install a new switch if necessary. |

|

Discharge hose is clogged or kinked |

Check the hose and rinse it to make sure there are no foreign objects in it. |

|

Exhaust filter is clogged. |

Depending on the level of clogging, the filter can be washed or replaced. |

|

Pump is clogged. |

Place a rag under the machine, disconnect the clamps from the hoses which are secured to the pump and make sure they are not clogged. Using a pencil, evaluate the rotation of the impeller - if a tight rotation is detected, open the pump using suitable tools. Inspect the impeller chamber, flush it, and then reassemble and reinstall the pump. |

|

Pump is broken |

Replace it with a serviceable part. |

|

Problems with electrical installation |

After disconnecting the machine from the mains, make an inspection of the contacts. If necessary, tighten and clean them. |

|

The timer is broken |

Replace this part with a functioning one. |

If the washing machine stopped during washing and won't drain, see the Washing + channel video.

Small leakage

|

The reason |

What to do |

|

The hose clamp is loose. |

Carefully inspect the clamp, seeing if there is any water around it. Loosen the clamp first and move it slightly, then tighten it. |

|

There is a crack in the hose |

If you find a crack in any hose, replace it with a new one. |

|

The door gasket is loose |

Replace the door seal with a new part. |

|

The tank packing is leaking |

Completely disassemble the machine and replace the bearing. |

How you can replace the bearing in a washing machine, see in the video of Vladimir Khatuntsev.

Heavy leakage

|

The Reason |

What to do |

|

The outlet hose slipped out of the drain riser |

Inspect the outlet hose and put it back in place. |

|

The sewer is clogged |

Check the condition of the drain, clean it and make sure it is draining properly. |

|

Discharge hose is disconnected |

Check the hose and put it back in place. |

On how to fix a leak in the washing machine, see the video by V. Khatuntsev.

If the washing machine constantly drains water and does not pick it up, see video by Vladimir Khatuntsev.

Strange Noise

|

The Reason |

What will be the noise |

What to do |

|

Small objects got into the drum |

Knocking or ringing, and if the sound has become squeaky and harsh, it is likely that an object has penetrated the tank and hit the heating element |

Be sure to check all clothing pockets before washing. If metal objects get inside the machine, it can cause serious damage to the machine. |

|

The door latch is broken |

There are sharp, frequent clicks or a buzzing noise, no vibration |

Push on the door and if the sound disappears, it is a sign that the latch should be repaired. |

|

The drive belt is loose. |

Whistling, squealing, or rustling, accompanied by a slight vibration |

Belt should be tightened or replaced to correct the problem. |

|

Drum or motor bearings are broken |

Quiet, rattling or knocking, with infrequent, low-level vibration |

Such a breakdown requires replacement of the bearings. |

|

Water intrusion into the electrical system of the machine |

A hissing noise, no vibration, possibly an ozone odour |

Without delay, completely de-energize the machine and do not touch it. With time, release water from the device and take things out. |

You can see the bearing replacement procedure in the video by Vladimir Khatuntsev.

For possible causes of loud noises when washing, see the following video by Vladimir Romanchenko.

Bouncing when washing or spinning

|

The reason |

What to do |

|

Too many things loaded in the drum |

Remove excess clothes from the machine and henceforth follow the manufacturer's recommendations on loading the machine. |

|

Clothes are not evenly distributed inside the drum |

After removing the items from the machine, untangle them and distribute them evenly, removing very heavy clothes. |

|

The machine has been placed on an uneven floor. |

Adjust the height of the feet of the machine so that the machine does not wobble. |

|

The ballast mount is loose |

Ensure that the bolts holding the ballast to the tank are sufficiently tightened. If the ballast is broken, it needs to be replaced. |

You can unscrew the broken bolt yourself. Refer to the video of Vladimir Hotuntsev.

The door does not open.

|

The Reason |

What to do |

|

Lock is on |

Most often, the lock is turned off within 2 minutes after the end of the wash. |

|

The switch that locks the door is broken |

When the machine is de-energized, the door lock will disengage and you can remove the laundry. Some machines have a cord that provides an emergency door release. When it is missing or you can not pull it, you will have to partially disassemble the machine by removing and repairing the door. |

|

There is water left in the tank. |

Make sure that the water has drained out and you have set the washing program correctly. In addition, check whether the pump is working, as well as whether the pipes are not clogged. |

If you need to replace the shock absorbers, repair them yourself using the video channel "Maxs K". The entire process is shown on Samsung brand washing machine shock absorbers.

Breakdown prevention

The most effective way to deal with washing machine malfunctions is prevention of malfunctions. It includes:

- Install the machine on a horizontal surface and adjust the height of the feet.

- Correct connection of the machine to the water supply, as well as control of water drainage from the machine to the sewage system.

- Evaluate water hardness and regularly apply descalers to the heating element.

- Careful inspection of the exterior and interior of the machine after each wash.

See Vladimir Hotuntsev's video on how to assess water hardness.