Grout joints of ceramic tiles in the bathroom with his hands

Grouting the joints of glazed tiles in the bathroom is both simple and responsible. It is necessary to know the correct implementation of this process and the right selection of grout mixtures.

Violated technology of grouting tile joints will lead to unsightly appearance, as well as the appearance of mold and mildew due to high levels of moisture.

Purpose

Grout mixture for tiles is a dry material based on cement. It is used to fill the joints between the laid tiles, which gives the surface a decorative appearance and protects it from moisture penetration.

Before applying the grout, tile joints are prepared and thoroughly cleaned of tile adhesive. Floor tiles must be vacuumed. The grout mixture is diluted with water to a creamy consistency and applied to the joints with a spatula.

Then, using a sponge or damp cloth, the grout is given a concave shape and smoothness. All the remains of the grout are removed from the surface of the tile until it hardens.

Choosing the right grout mix

The necessary grout mixture is selected after becoming familiar with its composition and properties. In the conditions of use in the bathroom, its moisture resistance is very important.

There are currently two types of grout available on the domestic materials market. The first is made on a cement base, and the second consists of epoxy resin.

Cement-based

Permeate moisture and are afraid of cleaning chemicals. By color, such grout is available in gray as well as white.

When using cement grout in the bathroom, use a hydrophobizer, which will make the surface waterproof.

Epoxy .

Composed of a resin and a kind of hardener. Joints made of such grout are resistant to various damages and the use of chemicals. They retain their color for more than 50 years. The cost of such grout greatly exceeds the price of cement-based material, so it is rarely used in domestic applications. Most often such grout is used when the width of the joints is more than 6 millimeters.

With latex

Joint grout with a small amount of latex added is also available in stores, which requires a coat of moisture-resistant varnish after application. In this case, the grout retains its natural color for a long time.

Leading manufacturers

Today, dry grout mixes on the domestic market are supplied by many manufacturers.

Almost a third of the domestic market is occupied by the company for the production of grout mixtures Knauf. Sales of products from this manufacturer are increasing year by year. In Russia, this company is known for over twenty years. Its branches are located around the world.

Dry grout mixes from the manufacturer Volma Widely enough known to Russian consumers. They are represented in dozens of denominations. The company is in the second place on the domestic market of grout mixtures. It has five working factories.

The most famous manufacturer of the modern line of grout tile joints is a German company called Henkel. It is engaged in the production of a whole range of finishing materials called Cerezit. All products of this popular brand have excellent quality, which is quite peculiar to German production.

Grout mix "Ceresit" ("Ceresit") does not absorb various contaminants and has a high frost resistance. This allows its application in the open air, as well as in rooms with an increased level of humidity. This grout mass is also used when finishing with modern tile flooring in any room.

The manufacturer of modern cement-based mixtures is a group of companies called Unis, which is in second place by total volume of products. All products have a five-year warranty on the results of finishing work with the materials produced.

Located in Russia, a branch of the famous French manufacturer Saint-Gobain produces large amounts of high-quality dry grout mixtures. The company's products are in demand in more than 42 countries.

Porous tile

When repairing the grouting of tiles with a relief pattern is made carefully, because the grout that has fallen on the surface of the tile clogs the applied relief and leads to damage to the material.

When working with this type of modern tiles, the grout mixture should be applied with a finger wearing thin rubber gloves. All grout remaining on the tile surface should be washed off immediately.

A small portion of the wall or floor covering should be set aside for the first batch of work. If a positive result is obtained in this area in the process, then you can safely perform the entire amount of work.

Selecting the color of the grout mixture for ceramic tile joints

Of great importance is the color of grout, which is used to grout the joints of ceramic tiles. Every modern manufacturer produces a wide range of colors of grout mixture, with the help of which the desired color is selected.

Joints of tiles with standard parameters, most often treated with a mixture of contrasting colors, giving the surface a rigorous and expressive look. In case of low-quality installation of tiles, such a color will emphasize all the deficiencies that have arisen.

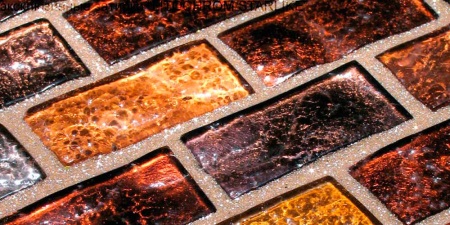

For fashionable smooth mosaic with a relief structure, the color of the grout mixture is selected in one tone, which allows you to make the structure noticeable. In this case, the contrasting color emphasizes the size of such a tile. Glass modern mosaic is most often treated with a transparent grout mixture.

To easily determine the color, a piece of ceramic tile is purchased to which the grout is matched. If it blends perfectly with the tiled surface, it can be purchased for the entire area to be treated.

Transparent tile grout

Colorless grout consists of hardener, glass crumb and epoxy resin. Keep in mind that this grout is not completely transparent.

Because of the glass fines in the composition, light passes through the grout with the transfer of the color of the material inside the joint. This grout is very handy for processing small joints of about 2 mm in mosaic compositions. Sometimes the mosaic can be glued on the grout.

The main purpose of such grout is to maintain the appearance of the magnificent appearance of the tile mosaic, the seams of which do not stand out, so it looks natural. The solution of transparent grout is prepared in small portions using electronic scales. This is required for a uniform, correct application and easy leveling, as well as for timely cleaning of the tiles from the remaining material.

If this is not done, within a day the epoxy grout will harden and a whitish film will appear, which can only be removed with an acid chemical cleaner. After two days, the residue can only be removed with chemical acids. After a week, the remains of the grout can only be removed with a grinder, which will damage the interior. The work carried out with such grout requires slowness and accuracy. First, it should be carried out with a trial run.

Instructions

When repairing tile joints are grouted in several stages:

- Materials are mixed to make a mortar.

- The mixture is allowed to stand for a better soaking.

- The mixture is mixed again.

- The distribution of the working mortar is carried out.

- The tile is cleaned of excess grout.

Grout for tile joints is prepared as follows:

- Liquid is poured into a dry bucket.

- Gradually added dry material, mixed with the help of an electric stirrer, which should be completely immersed in the solution to prevent air from entering into the mixture.

- After the entire mixture has been mixed with the added liquid, the resulting mortar is allowed to stand for ten minutes.

- The grout is thoroughly mixed until there are no lumps.

The implementation of grouting of tiles is carried out as follows:

- The prepared material is placed as a heap on the tiled surface.

- The mortar is distributed on the surface with a grout grinder, which is held at an angle of 30 degrees with respect to the tile.

- Then, using the grinder, the grout is pressed into the joint to fill it more densely.

The grout is used to fill any voids near the tiles that have formed after the glue layer has been applied.

It turns out that it's not hard to grout tiles.