What tile drill bit to choose?

The best finishing coating for the bathroom is considered a tile. It is strong enough, durable, not afraid of moisture and easy to clean. During or after tiling, it is often necessary to drill holes in the tiles to fix a mirror, furniture, faucet or outlets. For this purpose, special tile drills are sold, which come in different types.

Types of drills

Today you can buy the following types of drills on tiles:

Spear-shaped .

With their help, you can simply make holes for dowels, which serve as fasteners to install various objects. Drills can be used to work with porcelain tiles, but they wear out quickly. Since their cost is quite low, they are well suited for small jobs.

The characteristic features of such drills are:

- high efficiency;

- resistance to wear and tear;

- hole depth - up to 12 mm;

- affordable price.

Carbide drills

Such products are used to work with simple tiles and porcelain tiles. The main difference is the 1-sided sharpening with a sharp angle. This allows you to work rather quickly and efficiently.

Circular

They are also called "ballerina", because during operation they rotate and resemble the movements of a ballerina. They are used to work with different types of tiles, and the diameter of the holes can be 30-90 mm. The product consists of a main and an additional drill, a cutting plate. It is necessary to work with it at a low speed without strong pressure. So it will last much longer.

If you need a large hole

Sometimes you need to accurately drill a large opening for a pipe, socket or other purposes on the tiles. In this case, ballerinas or crowns are used.

The ballerina is made up of several components, the main one being the cutting drill. When the centering part is fixed to the drill, the cutting part is driven in a circular motion and breaks the working surface. This product is best used when you are not in need of non-standard openings or grooves. The drill should only be used without the percussion function and at low speed to avoid damaging the tiles. Also, using the device at high speeds can damage the ballerina. The disadvantage of the product is that with its help it is impossible to get an opening with an even edge.

But with the help of crowns you can get a surface with almost perfectly flat edges. The device device can consist of an alignment part or without it. If such is available, it is quite easy to drill a hole, because it is sunk into the work surface and does not let the crown move on the surface. Crowns can be drilled as a simple tile, as well as porcelain tiles, stone, marble.

Types of crowns

Today you can buy the following types of crowns for drilling large holes:

- With a diamond coating. They allow you to make slots of size 10-70 mm, but there are products and larger sizes. It is necessary to work with them in a water-cooled machine and to buy them with a centering part. It is possible to drill with them different tiles and stone, but when working with the second material, the product quickly comes to wear out, as it is quite hard. The drilling rpm should be between 200-500.

- Carbide-tungsten. They are excellent for working with tiles, porcelain tiles, bricks and stone. The result is excellent grooves that can be used to attach various shelves, sockets. The kit comes with 4 different bits.

Alternatives

There are also universal drills, used to create any holes in various materials, natural or artificial. Such products have a deep spiral on the sides, through which dust and other materials are removed from the hole. They are made of special steel. A special sharpening technique makes these drills maximally durable and effective for working with materials of any density and hardness. You can sharpen the drill bit yourself.

Selection tips

Since any tile - it is quite a fragile product, it is necessary to approach its drilling with the utmost care. First, you need to choose a working tool. If you need one or two small holes, it is preferable to use a hand drill, which does not produce vibrations when working. But not everyone suits this option. Then a hand drill without a percussion function is used.

The question of choosing a drill is decided depending on the work to be done. Lance-shaped products are better used when it is necessary to make small holes. When making a purchase, it is necessary to pay attention to the fact that the cutter of the drill should be harder than the working surface. Specialists advise to choose products with a diamond coating. And although it is slightly more expensive than other types of drills, its high quality allows you to use it for a large amount of work. And to make a couple of holes once a year, you can buy an inexpensive drill bit with a pobedite tip.

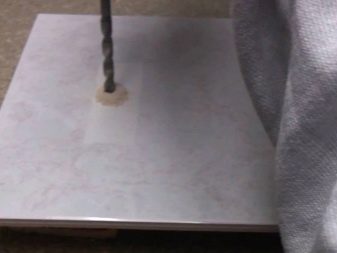

Drilling Technology

Incorrect drilling technology can cause damage to tiles or other materials.

To get a hole on the laid tile with the most even edges, it is necessary to minimize the pressure on the drill. Otherwise, the material may crack. The same applies to the lowest rpm to avoid vibration and drill backlash.

When drilling deep holes, surface heating can occur. Therefore, it is necessary to stop work for short intervals and moisten the drill bit and tile with water. The tool is then disconnected from the power supply.

Since tiles have a slippery surface, it is not always possible to make the hole where you want it the first time. There are the following tips for this:

- At the marked point, you can make a small depression with a hot screwdriver or file.

- You can put painter's tape on the tiles.

- Correcting pencil for stationery makes a special mark, which will have a slight roughness.

It is easier to perform drilling on unplaced tile. To do this, it is soaked in water for about 30 minutes to avoid splitting. The drilling itself is done on the back side, where there is no glazed coating.

Peculiarities of porcelain stoneware

Porcelain stoneware is much stronger and harder than ordinary tiles. The general technology of its drilling is the same, but with some nuances. So, to work with it, drills or bits with a diamond coating, made by the diffusion-vacuum method, are used. Such products are as strong as possible and resistant to wear and tear. Drilling takes place with a simple drill or a rotary hammer drill without a blow function.