Fittings for WC with bottom feed

The cistern of the toilet bowl with a bottom connection is a container, from the bottom of which the hose with water enters. In this tank and stores water until the procedure of draining. On top of the tank is a lid. In modern toilet bowls on the lid is a flush button, but in some models it is mounted on the side, if the cistern is located high above the bowl. The bottom supply line is considered the most inconspicuous and attractive option for the toilet. Nevertheless, it is quite difficult to create. To do this, first connect the tank to the water supply, and only after that you can mount the tank to the wall or the base of the toilet bowl.

Used in the toilets with a bottom supply are divided into two categories:

- Shut-off;

- Drain.

Types

Shut-off .

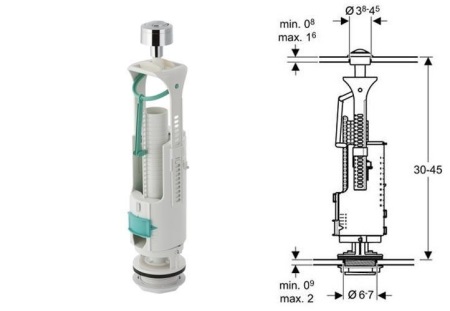

The design of this fitting includes:

- Float;

- Guide;

- Stem;

- Glass;

- Diaphragm valve.

This toilet has a drain that works as follows:

- When the tank empties after draining, the float goes down the guide;

- Then the thrust exerts force on the valve, thereby opening it;

- Water from the plumbing fills the tank capacity;

- The float chamber thus begins to move to the level restricted by the thrust;

- The valve closes and the water flow stops.

Drain

The drain fitting is a system for draining water. In the cistern it is attached by means of a coupling nut, mostly made of plastic. To seal the joint, the pipe drain valve put gaskets. And this should be done before mounting the valve itself. There is also a gasket between the bowl and cistern, which allows you to make the joint airtight and prevent water from leaking on the floor. The shape of the gasket used depends directly on the model of the toilet bowl purchased.

The tasks of the drain system:

- Provide a drain when the appropriate button is pressed;

- Provide an emergency discharge (a special gutter is provided).

Design features

To remove the flush mechanism for models with the top location of the button, it is necessary to rotate it counterclockwise, after which the button is easily removed, as well as the entire lid.

Not uncommon are the cases of toilets with a lower supply, where there are two buttons. This is done in order to save water when draining. The small button drains a little water, the big one drains twice as much.

There are different internal contents of the tank. Sometimes a direct flush is used, where the water from the tank goes into the bowl. Other designs have a reverse flush, where the direction of water flow is reversed, which adds noise.

Advantages

- Have an attractive appearance, because the pipes are hidden from the eyes of the user.

- The toilet itself with such a connection is often made in an original form and with an unusual design.

- The system makes practically no noise, there are no annoying sounds of pouring water.

- The most practical option, because it is highly reliable and rarely needs repair and maintenance.

Disadvantages

- Difficult-to-install.

- The need in some cases to completely dismantle the system to repair the cistern.

- Despite the rare cases of failure, if it happens, it is difficult to replace a single design element. It is better to change the whole unit at once.

- Such toilets are focused mainly on America and Europe, so with connection problems may arise because of the unique adapters, unusual for our region couplings. Therefore, the toilet bowl and all the accessories for connecting is better to buy at once in the same store.

Installing .

It is quite possible to perform the installation yourself. However, please note that this process is characterized by increased complexity, if compared to the toilet with a side supply, for example.

Anyway, the sequence of your actions should be as follows:

- Each product has its own data sheet, where there is a detailed installation instruction. Familiarize yourself with it.

- Carefully study everything that came with the toilet bowl. As a rule, the manufacturers provide the necessary fasteners and connectors.

- Install the lower part of the toilet bowl, fixing it in the right place and position. Make sure that the length of the pipes is enough, and the supply line will reach their places.

- Now the cistern is mounted. Just at this stage it is necessary to install the internal structure.

- As practice shows, the first to mount the fill valve, and at the junction of the tank. For this you will need sealed rubber gaskets and adapters.

- In some cases, simultaneously with the filling valve mount the inlet valve. But it depends directly on the chosen model of the toilet bowl.

- To assemble the other elements will not be difficult, if you have at hand the instructions. The toilets are often unique in its design, because we can not give general advice on assembly.

- All structural elements assemble exclusively by hand, tools are not required. At the same time, make enough effort to ensure that the connections are strong.

Frequent problems and troubleshooting

- Over time or with improper installation, leaks may occur on the outside of the drain spigot, when flushing or from the cistern itself. This phenomenon indicates only one thing - the gasket is leaking. To fix the situation, tighten the plastic nut that connects the tank and the spigot a little. If after that the leak did not stop, then shut off the water, unscrew the nut and pull the branch pipe down. Pull, the gasket should show up shortly. Remove it, and at the tip of the spigot make about 10 wraps of FUM tape. Put the element back in its original position and tighten it with the same nut.

- Water is not coming out. Check the level of liquid inside the tank. According to the rules, this should be the top level. If it is small, sometimes it is enough to adjust the angle of the float lever. To adjust, turn the plastic valve screw. A screwdriver will be needed here. For brass products, the lever is unbent by hand or the nut on which the float is attached is loosened and shifted upward.

- Drain is jerky. Inspect the drain lever fasteners. It is probably loose, and then the lift rod will not rise vertically. To fix the problem, simply tighten the bolt and adjust the lever in the desired position.

- The release lever is out of order. There are special universal elements for replacement, which are not a problem to buy today. In some cases, substitutes have to be shortened. The main thing is the absence of coupling between it and the siphon block.

- Lime scale. Get rid of it can be improvised means - citric acid and water. You need to remove water from the drain siphon, apply a paste of the above ingredients. You will have to leave it for the night. Such a mixture is excellent for dealing with plaque.