Underfloor heating in the bathroom

Thanks to the use of a warm floor in the bathroom, the comfort of living increases, humidity decreases, and it becomes easier to maintain the air temperature in this room. In most bathrooms and toilets, the floor finishing material is tile. And since this material is quite cold, additional floor heating will only be a plus.

Nowadays, the floor heating is not something exotic - it can be installed in any bathroom. Such a source of heat will prevent the development of mold and mildew in the bathroom. You will not worry about the health of the household, and splashes on the floor will quickly dry up. Especially convenient is a warm floor during the period when the central heating is off, and the air temperature is low.

Heat will come from below, providing a comfortable microclimate in the bathroom. Hiding the system from view is considered an advantage compared to even the most modern radiator, which takes away space, and does not decorate the room. In addition, you will save resources, which is especially important for a private home. True, initially you will have to spend money on the arrangement of the system, but all the expenses can be called justified.

What kind of underfloor heating should I choose?

When you decide to make a warm floor in the toilet or bathroom, you need to decide on the type of system.

To insulate the bathroom floor, a special electric cable or electric element of the film type is used, as well as water heat transfer medium. In all cases, the system provides for the presence of a temperature sensor and thermostat.

Note that the variant of the water floor is a good choice for a private home in which autonomous heating works. Such a warm floor is practically not installed in multi-storey houses, because it is forbidden to connect to the central heating (additional load can be a factor leading to a failure in the heating system), and the installation of a separate boiler is expensive. Therefore, the use of electric systems is more often recommended for apartment buildings. Many people prefer the infrared version, as it does not require raising the floor level.

Pros and cons of the varieties

As already mentioned, all varieties of warm floors can be divided into 2 types - electric (cable and film) floor and water. Let's discuss the features of each, assessing the advantages and existing disadvantages.

Water

Water heated flooring is an environmentally friendly warm floor, which heats gradually and does not damage the tiles. It uses hot water and requires the installation of a special pump responsible for its circulation. Its costs are relatively low when compared to electric.

The disadvantage is the need for permission for installation (installation is not allowed in an apartment building), as well as the possible risk of leaks.

Electric

Electric floor heating is easier to install by placing a heating cable or film coating under the tile. You can do the installation yourself. It is most often chosen for heating small areas. This floor can be used for a very long time. When installing it, you do not need to think about central heating, so the electric floor is suitable for any room.

The disadvantages of such floors are the lack of environmental friendliness, the impossibility of laying a heating cable in the location of the plumbing, as well as the possible deformation of the tiles, as a consequence of rapid heating of the floor.

Choosing a film version, you will not have to raise the floor and do screed. And because the connection of heating elements is not carried out sequentially (as in the cable subspecies), and in parallel, even if one strip burns out, the function of the warm floor in the room will remain.

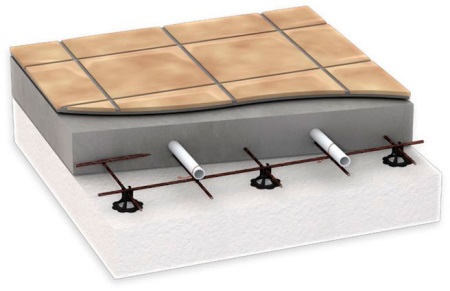

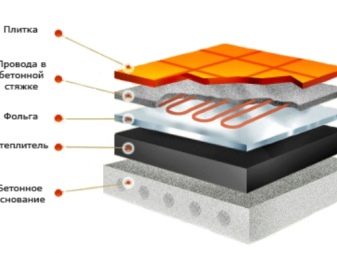

Peculiarities of installation: the "pie" of the underfloor heating

The surface must be well cleaned and level (only minimal irregularities are permissible). To ensure that the thermal insulation layer is not deformed, a solution of sand and cement, which is applied in a thin layer, is usually used for leveling.

Before starting the work, you need to find out whether the installation of underfloor heating in the bathroom in the building is allowed. If it is planned to build a screed, then on a cleaned basis lay materials that serve as a vapor and waterproofing. They may be represented by poured and rolled materials, as well as coating substances.

If the poured material includes bituminous components, bitumen should be allowed to dry well before laying the thermal insulation foam material.

Rigid mineral boards, cork material, polystyrene foam or special foil are used as insulation. Laying them, it is important to avoid the formation of gaps and slots (if the mortar penetrates into them, this will cause temperature bridges).

Installing water underfloor heating

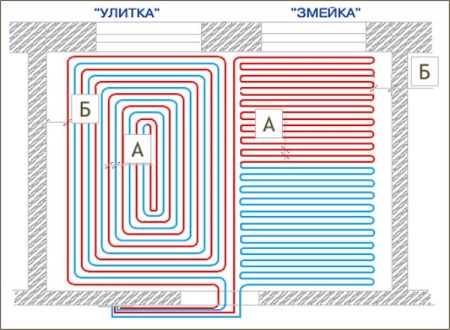

The first task will be to replace the iron risers that carry the hot water with plastic ones. After that, it is necessary to make a diagram of the future floor heating (location of pipes).

After laying waterproofing, a rough screed, located 5-7 centimeters lower than the final floor covering will be poured. To screed does not crack, it should be watered 3-6 days.

After that lay out the foil and proceed to the installation of the water floor. Referring to the scheme, fix the plastic pipes with a pitch between their coils of 15-20 cm. After connecting the system to the supply riser, equipped with a regulating valve, turn on the water to check the work of the mounted floor.

The last steps will be the installation of the second layer of screed and the laying of the finishing material.

Electric cable installation

The first step is to make a cable laying diagram, determining the location of the sensor and thermostat. The scheme is drawn on the plan, taking into account the bypass of plumbing fixtures and a certain step between sections of cable. This scheme must be maintained after installation.

The next stage of the work is thermal insulation. On a flat base (irregularities are allowed up to 7-8 mm) laid insulation, which is often supplemented by foil. If the base is uneven, a concrete screed is made.

To install the cable is convenient to use a metal mesh, on which it is fixed. Such a grid will give the structure rigidity, and also prevent the intersection of the coils of cable. It is also convenient to use ready-made thermal mats.

After checking the resistance of the cable, the electrical and thermal parts are connected close to the thermostat. When installing the thermostat, place the sensor in the corrugated pipe and place it above the level of the screed.

Next, after checking the resistance of the cable, the integrity of all parts and the connection sleeve, the base is poured with cement with an even distribution of it on the floor.

It is important to avoid the formation of voids in the screed, so as not to reduce heat dissipation and not to cause local overheating. The thickness of such screed will be 3-5 cm. The system is turned on not earlier than a month after the filling of the screed, otherwise it may cause cracks and cable damage.

Installation of the film floor

The film emits infrared radiation and is a strip width of up to 1 meter. Such strips are sold packed in polyethylene. If it is necessary to cut the material, it is done according to the markings on the film. The film coating can be installed under any finish, and since the thickness of this film is small, the level of the floor is virtually unchanged.

If the floor heating is installed as additional heating, it is enough to install the film only on 40-50% of the area of the bathroom. The film should not be placed under furniture, washing machines, plumbing and other items. It should not be placed close to the wall - it is desirable to leave a gap of at least 10 centimeters.

If you compare with the installation of water and cable options, this subspecies of underfloor heating is the easiest to install. That is why it is the most accessible for independent installation. After dismantling the old floor covering, assess the condition of the base. It is important to ensure the horizontal surface of the base with irregularities up to 3 mm. If the differences are larger, the coating can be sanded or filled with a self-levelling mixture.

Next, you just need to lay the heating elements down with the current-carrying side in the required amount on the waterproofing material. Usually leave an empty space of 5 centimeters between the strips. To fix the strips is used construction adhesive tape, which prevents the film from shifting during work. The cut lines should be treated with bitumen insulation.

After connecting the sensor and the thermostat, check whether the floor heating works. To insulate the heating strips you can use the wet method (install a screed) or the dry method (cover with protective foil). If a screed was used, the system is not turned on for a month.

A warm floor is a must if you have a first floor, your house is poorly heated and you have a child. We did, now we're not freezing and we're very happy.