Metal outer corner for tiles

Assignment and advantages

When installing tiles, there are various nuances, which at times cannot be avoided. Even the fact that you have purchased the most expensive material does not mean that when you work with it, it will not break off and leave you with the indignant impression of poor quality goods. Therefore, such a little thing as a corner, you will need in any case.

So, corners for tiles have a number of advantages:

- Will help you to hide incorrect corners;

- Your material will be reliably protected from condensation and the formation of various kinds of microorganisms (fungus, mold, etc.);

- the appearance of chips and cracks will be minimized;

- Tile less wear and tear, and the view becomes more elegant;

- easy installation;

- no sharp corners;

- resistance to accidental impacts.

Types

There are a huge number of models of corners.

By design, outdoor varieties can be divided into the following categories:

- soft - material: polyvinylchloride base and silicone edges. Have a different design. Are usually used under a different decor to emphasize the features of something or hide flaws;

- rigid - material of manufacture: aluminum. To use them, all the walls must be flat, and the corners correspond to 90 degrees. Properties of these corners: lightness, strength and corrosion resistance.

- semi-rigid - are made of PVC. They are used in straight and curved connections. Properties: convenience and elasticity in use.

It is worth separately identify corners made of brass and stainless steel. Brass corners are very heavy and used mainly for that category of tiles, which is very bulky and the load on it is very high, and the corners themselves from this material is almost impossible to bend. The use of corners made of stainless steel is reduced to those designs where you want to reinforce. A distinctive quality of these corners is that they are not subject to oxidation and corrosion.

Installation

Assembling the floor bracket

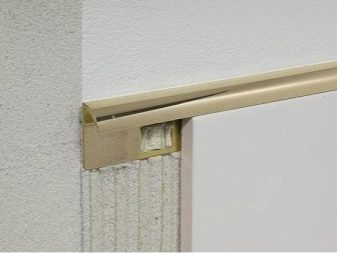

Aluminum corner is mounted as follows: it goes to a distance of 2-3 cm under the tile and is fixed with glue in the space from the floor to the ceramic.

In areas where people are constantly present, such a corner would be reasonable to strengthen with a self-tapping screw.

Mounting the wall bracket

Measure the walls and floor. You need to find the deepest points, because the gap may not be calculated correctly. If this is not done, then you can end up with a lack of space for tiles, which will lead to cutting the wall, or, conversely, will have to deal with plastering. Fasten the wall corner begins from the ceiling towards the floor. It is necessary to connect with self-tapping screws and corks, previously hammered into the wall. The interval of screwing screws varies approximately from 3 to 4 places for each meter of the wall. It is necessary to place each corner in parallel to the previous one. Initially, you need to nail the fastening tools - screws, and as soon as you achieve maximum accuracy, only then they should be completely screwed.

Recommendations

Selection of the outer corner should be made according to the thickness of the tile material. In addition, it is necessary to deal with the issue of the joints, what it will be - cut or flat. It is important to know that the corner combines as two cut corners, one flat and one cut and two flat. Take measurements in advance and go to the store with them, because you will need different pieces of corners. These elements of fasteners should be bought with a reserve of length, because during installation some of them may get damaged.

Companies that make tiles, recommend certain manufacturers of corners, as these recommendations are based on specific tests of this tile and this corner. This is worth paying attention to.

Do not forget to ask for a certificate of quality from the seller - so you protect yourself from fakes.

On the installation of the corner on the tile with their own hands, see the following video.