How to cut tiles?

Preparing for the job

Ceramic, glazed, porcelain and gypsum tiles - quite a convenient material for finishing walls in the living room. But before you begin its direct installation, you need to learn how to properly cut tiles at home. After all, the flatter the tiles are cut, the better the end result will be. Rarely can a tile be so well sized that it does not have to be cut. When tiling, for example, an apron in the kitchen, to lay only one piece of tile is unlikely to be possible, especially at the corners, projections, locations of pipes and outlets.

Before you start cutting tiles, it is necessary to take it out of the packaging, carefully inspect and sort it, since in any batch of even the highest quality goods there are small errors and defects, such as:

- mismatch of shades

- unevenness of the glazed surface

- discrepancies in length, width or corners of tiles

- chips and cracks received during transportation

Of course, with the above in mind, Material should be bought with a reserve, usually enough extra 10%. By the way, on the discarded material you will be able to practice and "get a hand", if for you cutting tiles is not yet a well-established skill.

After sorting, the tiles should be soaked in water for a period of one to three hours (the more modern the cutting tool, the less soaking time is required).

During this time, you should prepare:

- a table, stool or board for cutting

- a pencil, marker or felt-tip pen (for marking)

- a long ruler or measuring tape

- square, ideally metal

- respirator

- goggles

- earplugs/headphones (for use with a machine or grinder)

With what to cut?

To begin, let's list the most common and available tools for cutting tiles:

- roller glass cutter

- cutters

- hacksaw

- electric jigsaw

- handheld tile cutter

- mechanical tile cutter

- electric tile cutter

- circular saw

- angle grinder

If you need to cut just a few tiles for personal use, then the simplest tools that are available in almost every home are enough. But if you want to earn money on laying tiles and, accordingly, its cutting, it will be necessary to buy the appropriate professional power tools.

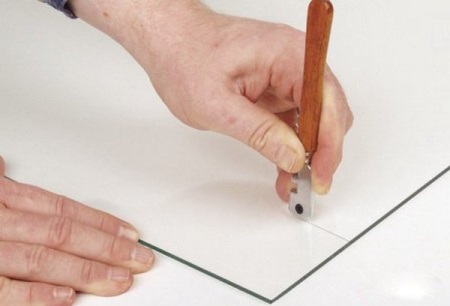

Roller glass cutter is a wooden handle with a small diamond rotating wheel at the end. Cutting tiles with a glass cutter is the most well-known, though not too simple method. It is used for small amounts of work and on not too thick and strong tiles. To cut a tile with a glass cutter, you need to use a ruler, with pressure to move the roller from edge to edge along a predetermined line. It is not allowed to tear the tool from the tile surface, and It is not recommended to run the glass cutter over a line that has already been cut once.

The glass cutter will not cut the tile all the way through, it will only scratch the stripe. Next, you need to carefully, taking your time, break the tile, placing it with the cut line on the edge of the table or board, lightly tap it with the handle of the glass cutter and press on the hanging edge. As a result, the material should crack just along the outlined line. After separating the parts, the roughness can be sanded down with sandpaper or a file.

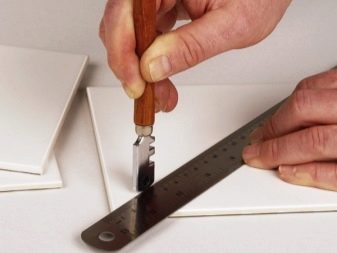

Pliers are usually used to break off pieces of tile. They are used when it is necessary to cut the tiles for openings in different places: under pipes, platbands, window sills, outlets, etc. Pliers do not cut in the direct sense of the word, but break off small pieces of tile along the cut line. The cutters themselves have two carbide-coated clamps in their design - the upper one cuts through the shiny glazed layer on the tile, and the lower one serves as a support. Working with cutters is as follows: the outline of the cut is drawn on the tile, clamp the tile with cutters, clamp both halves of the tool and break the tile along the marking. If necessary, clean the resulting cut with a file.

You can also cut the tile with a hacksaw. It is better to buy a special hacksaw for ceramics, outwardly it does not differ much from other varieties of hacksaws, such as metal or wood, with the only exception that its blade is covered with a special coating of tungsten carbide. The main advantage of using a hacksaw is that the cut edges come out flat, without chips, nicks or roughness and therefore require almost no additional sanding.

Jigsaw - Quite versatile and functional tool. You only need to buy a special abrasive saw (so-called "rope") to work with tiles. It can be used to cut tiles evenly and accurately, as well as to make holes and shaped cutouts in the product. To cut a tile, first fix it in place, then turn the jigsaw on medium speed and make a through cut along the pre-defined contour.

Manual tile cutter Reminds in its appearance pincers, only with the difference that one of their tips has a ledge, and the other - a characteristic cutout. In addition, at the edge of the tool is placed a roller diamond cutter. Using such a tile cutter is simple enough. First you need to cut through the glazed side of the tile with the roller. Then, clamping the tile with pliers, break the cut exactly along the line. It is important to make sure that the overhang is on the front glazed side, and the notch is on the back matte side.

Mechanical tile cutter is similar in principle to a large glass cutter with additionally attached guides and a lever. When using a mechanical tile cutter, the tile is placed on the stand under the guides and the lever is pulled back to the nearest position. The tile should then be aligned with the line and the cutter roller positioned on the edge of the marked line. Then you need to gently move the pick roller with the lever forward along the line, pushing it slightly in the process. At the end of the operation, the tile itself splits exactly along the cut line. However, the disadvantage of such a tile cutter is that they will not be able to cut a piece of less than 5 mm.

Electric tile cutter at home is used quite rarely, it is mainly in demand there, where you have to cut tiles on an industrial scale. Tiles are cut with this tool by means of a rotating diamond-coated disc, which is permanently wetted with water from a special container. The material must be fed to the disc carefully, otherwise the tile may crack.

The main advantages of such an electric tile cutter are the absence of dust during work, as well as a perfectly smooth shape of the cut, without chips and cracks. Significant disadvantages, however, are that this tool during work makes a rather loud roar, rotates very quickly, as well as dribbling sparks around itself. Therefore, special precautions must be taken when working with it.

Circular saw is also rarely used at home, as a separate workshop is needed to work with it. Such a tool is a full-fledged machine, equipped with a toothed disc. For cutting tiles, a special diamond disk for dry cutting is required. In the process of cutting, the prepared tile is pressed against the table and gently pushed forward along the planned line.

But in almost every household you can find a grinder. With this tool it is also possible to cut tiles, you just need to take care to buy a diamond cutting disc and set it in the direction of movement of the tool. For cutting, it is necessary to preliminarily draw a marking on the tile, and then carefully make a cut in it, gently advancing the tool at medium speed "from yourself". The disadvantage of working with a grinder is a large amount of dust and sparks, so it is necessary to observe all possible safety measures at work. In addition, the edges of the tiles after cutting with a grinder can form small chips, which will need to grind.

Methods of cutting at home

Professionals prefer hydro-abrasive and laser cutting, which are performed on special machines. Their advantage is that there is practically no significant mechanical or thermal impact on the surface of the material being processed. Waterjet cutting mixed with abrasive or a laser beam controlled by a modern computer are mainly used in metal work, but they are also unbeatable when cutting particularly hard floor tiles. A wide variety of shapes can be cut perfectly on these machines.

Curved and curved cuts (e.g. rounded corners, diagonal or 45°) can also be made at home. In this case, it is best to use an electric jigsaw or an electric jigsaw with a diamond thread. With their help, it is possible to perform quite fine work, even on such a particularly durable material as porcelain stoneware.

With ordinary thin glossy tile wall tiles can work with a glass cutter with a roller. But if there are a lot of such tiles, it is better to buy a special tile cutter. Also, if you do not have power tools, you can try working the cuts of ceramic tiles or mosaic tiles with pliers, and then grind them thoroughly. The main thing is not to "bite off" the nicks in very large pieces.

Gypsum tile "like a stone" is the easiest to cut, as the gypsum-polymer material, of which it is made, is quite plastic. Gypsum tiles can even be cut with a regular wood saw, but a fine-toothed hacksaw will work best for cutting such tiles.

How do I cut a hole?

When cutting holes (for example, for pipes) an ordinary drill can help. The most high-quality and even holes are obtained with the use of an attachment in the form of diamond crowns, but the high price of such products does not allow you to purchase them to perform small-scale work.

If it is necessary to make a through hole in the tile, you can also use a special drill, called a "ballerina". It resembles an ordinary compass and functions on the same principle. To obtain the hole, first remove the glaze from the face of the tile with a hammer and chisel, drill a hole, and then manually adjust the desired diameter from the center of the cut element to its cutting edge. You should drill only at low speed, as too high speed of rotation provokes mini splinters on the edge of the cut.

Tips

To achieve a perfect result, only a good tool is not enough, it is important to know a number of nuances, with which professionals of their business can introduce. Here are a number of tips on how to cut a tile quickly, qualitatively and with minimal losses.

With manual methods of cutting tiles, it is recommended to additionally use the so-called chair - a rectangular box with special slots (straight and at an angle of 45 degrees) on the sides for a more accurate and even cut.

If you do not have a sturdy ruler to draw the line, it can be replaced by another tile with a straight edge.

The tiles should be cut with precise and precise movements. А To avoid splitting the tile when breaking off a cut piece, you can duplicate the shallow cut line on the underside of the tile. This can be done with any cutting tool you have on hand.

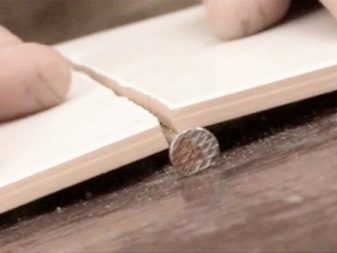

When cutting an especially strong tile (such as porcelain tile) with a grinder, experts recommend that, after making the cut, set under the tile stop (for example, a nail or a thin rod of metal), and only then, pushing on both parts, break it.

When making a curved cut with a grinder, you should not try to work large pieces of tile at once. It is better to begin by breaking off the piece with cutters, and only afterwards to trim it with a file and sandpaper.

You can also see the ways of cutting a tile in the following videos.