Underfloor heating under the tiles with his hands

Warm, cozy, comfortable atmosphere in all respects in the house depends largely on the presence of a modern heating system. It can be a traditional option of heating the room with an even distribution of heat through the pipes. However, this option of heating is not the only one. For example, today, many people have already had time to appreciate the scheme of heating, for example, in the bathroom, by installing warm water floors under the tiles.

What is this heating system?

The device system

Modern underfloor heating is an incredible comfort and safety. This is a worthy alternative to all traditional types of heating in the house, allowing you to achieve a constant and even heating of the room. The correct scheme of heat distribution in the house - is the key to the health of the household. In such a house will not remain cold zones. Works on installation of the system can be done by yourself, especially if you already have experience in repair works of this kind. The finished system works without failures, provides a fairly economical power consumption and allows you to control the temperature regime in the house.

Design features of under-tile bathroom floor heating

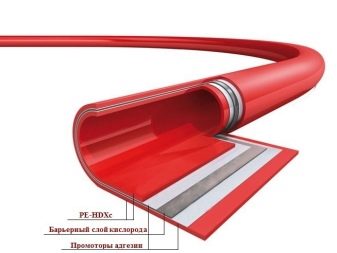

A real underfloor heating consists of several layers:

1. A layer of gyroinsulating substrate to create a warm floor. Materials for waterproofing may vary depending on the method of installation. The material can be laid on the ground, on top of which the screed will be carried out. In this case, you can use roofing felt or thick polyethylene. You can do without screed, but then you will need to lay a waterproofing membrane.

2. A layer of insulation. A special dense layer of polystyrene foam provides an insulating effect. Sometimes basalt wool is used as an insulation layer. But this material is used last, as it is hygroscopic and in the case of leaks can get very wet. Such insulation quickly loses its original insulating properties.

3. Next you need a reflective foil layer. This can also be metal plates with special channels.

4. The presence of pipes.

5. The quality of underfloor heating is affected by the presence of a solid base. If you do not make a screed under the system, then for a solid base it is necessary to lay several moisture-resistant sheets of plywood. For example, it can be gypsum board, OSB.

It is important to keep in mind that as a base for installing the system you can use both wood and gypsum board only with good thermal insulation qualities.

Warm water flooring in finished form can have different thicknesses. Here, much will depend on the type of installation. You also need to consider the presence of pipes, the thickness of the insulating material, screed (if any), laying sheets of plywood on the subfloor. The thickness of the screed at the base of the floors has no more than 3 cm. The thickness of the insulation may vary depending on the material used and the place of installation (on top of the ground, on top of the slab). Plasterboard sheets or mats are laid no thicker than 8 cm. For pipes in mats (or sheets) there are special channels, the depth of which depends on the thickness of the pipes. The thickness of the pipes themselves can be disregarded.

Structural features of underfloor heating systems

The system of floor heating under the tiles is arranged as follows:

- A boiler is installed. Today, different types of boilers are installed in homes. For example, electric, as the most affordable option of equipment. Although most homes install gas boilers, as the most common option for bathroom heating systems and the most economical. When choosing a gas boiler, you need to pay attention to models with a closed furnace, which provides protection of the room from the products of combustion.

- The presence of a manifold in the system. It is necessary if the floor heating is the only source of heating in the house. That is, there are no other pipes and radiators in the room. In this case, the heating area is taken into account. So, for one floor circuit (40 m), 100 m of pipes are required. The circuits are connected to the manifold. In this way each circuit in the heating system is regulated. And in each circuit is installed two combs, consisting of supply and return pipes, as well as air valves and adjustment cocks. For all this construction with loops, a special niche or a manifold cabinet is allocated.

- Availability of a pump. For a floor heating device, a pump is necessary to ensure the circulation of heat from the boiler to the manifolds. The pump is just between them and is equipped with a water purification filter.

- Installation of the floor heating. The design consists of pipes (metal or polypropylene) with a cross section of 1.6 cm to 2 cm. The pipes are laid in coils in a spiral around the perimeter of the room. In the center of the room, the coils are turned and the return is started.

Advantages and disadvantages

The heating system in the house in the form of water-heated floors affects the comfort of all household members. But as with any technology, water flooring can have its advantages and disadvantages.

What are the advantages of a heating system with underfloor heating?

- This is one of the options for heating the room, which provides a wide coverage of the area at a relatively low energy cost compared to the system of radiators for heating.

- Water floor heating allows you to abandon all other methods of heating and can replace other heating devices in the house.

- Underfloor heating when properly installed provides an even distribution of heat in the room.

- Underfloor heating system is designed for long-term operation. The warranty for the heating system is 50 years.

- With underfloor heating it is easy to create a warm atmosphere in the house at a comfortable temperature and normal humidity.

- In addition, thanks to the underfloor heating system, there is no need to install unaesthetic structures in the house for additional heating. It expands the boundaries of space and makes the room more comfortable, not limited in layout.

- At the same time, underfloor heating does not limit the owners of the house in the choice of additional heating systems, if necessary.

- The floor heating system makes it easy to regulate the temperature regime in the house.

- Constant heat and uniform heating of the room leave no chance for fungus and mold to develop.

- Floor care does not require much effort. It is enough to make a quick wet cleaning.

- Warm water flooring guarantees safety, provided the installation is carried out competently.

And yet, despite the many advantages of warm floors, you should not forget about the possible disadvantages of the system.

What are the disadvantages of heating with underfloor heating?

There are not many of them:

- In an apartment building, the installation of underfloor heating is not possible due to the design features of the central heating system.

- Installation of underfloor heating in the house requires certain skills of work. Therefore, to ensure the smooth operation of the system, you need the help of a specialist.

- For the functioning of the heating system with water floors requires the installation of a water pump.

- As a result of illiterate installation of the system, leaks and their consequences are possible.

Preparation for installation

In order to ensure the smooth operation of the underfloor heating system, it is important to prepare the substrate before laying the pipes. Initial preparatory work ensures the quality of the overall system. Therefore, it is important to clean dirt and debris from the subfloor for the installation and remove all kinds of potholes, chips, unevenness and protrusions over the entire area. Without this, the floors will have height differences that will lead to uneven heat distribution in the room. Levels are used to adjust the height of the floors.

At the next stage of preliminary work on the preparation of the base of the installation is performed screed. It must be perfectly flat, of equal thickness along the entire perimeter of the base. This can ensure the quality and even distribution of heat. Then you can proceed to the work on the laying of the thermal insulation layer. This material is necessary to minimize possible heat loss. Waterproofing film is laid all around the perimeter of the room. For this purpose, a special tape with a width of about 10 cm is also used.

After this you can carry out full thermal insulation. The thickness of the insulating material depends largely on the design features of the floors, on the location of the room. In some cases, the thickness of insulation will have to be increased to ensure the preservation of heat. Thermal insulation can be carried out with a variety of materials, for example, you can lay a strong and dense foam.

Technology and installation

Installation of warm water flooring is carried out in two ways:

- laying of pipes is carried out on a concrete base;

- The laying of pipes is carried out on a polystyrene base.

The principle of operation in each method of laying the system is almost identical.

The water floor is installed in the following sequence:

- The rough floor is prepared. It is cleaned from dust and debris, then a layer of insulating material (it should be at least 30 mm thick, with a density of 35 kg/m3) is laid on it. For example, it could be extruded polystyrene foam. Today, other materials with ready-made grooves for pipes are also popular.

- Throughout the perimeter of the room, a damping film is laid. It helps to compensate for possible thermal expansion of the screed.

- The next step is the laying of the compacted polyethylene film.

- Now you can start laying the reinforcement mesh. Reinforcement is needed to fasten the system. For pipes, a network of expansion joints, which additionally protect the corrugation. The grid is also sometimes laid on top of the pipes with another layer to give the construction greater rigidity.

- Then the installation of the warm floor directly from the pipes is carried out in a snake at the rate of - 5 m of pipe per 1 m2 of the area. The larger the area of the room, the greater the number of diverter loops required.

- Then follows the pressure test. Test the system is carried out with a view to possible defects in the work, which must be eliminated. One day is enough to test the system.

- The next step after the pressure test - the filling of the screed (thickness not less than 6 cm), which ensures optimal heating and eliminates cracking of the floors.

- The final stage is the laying of the final coating (tiles).

Tile laying

When installing underfloor heating systems, traditional materials are usually used:

- ceramic tile,

- stone,

- ceramic tile, stone, porcelain granite.

Underfloor heating provides the laying of smooth tile, which provides the least heat loss. When laying such tiles, it is important to ensure that there are no voids under the material, otherwise this will lead to further temperature deformations - the tile will simply begin to crack.

You can put the tiles after the pressurization and testing of the system, when the concrete screed finally dried up. To speed up this process, you can use a heat generator. This will also provide a stable temperature in the room for this time.

The tiles are laid according to the preliminary marking on the base of the floor. According to another scheme, the tile is laid from the center of the room or from a corner. The tile from the underside is treated with a special adhesive with a toothed trowel. The tile should be immediately pressed to the substrate and so hold for the first few seconds until it fully sets. For this purpose, regular tile glue is used, and the joints are grouted with a special compound.

After laying tiles, it is necessary to treat the seams. It is necessary to achieve their evenness and uniform thickness (1-3 mm). To do this, you need to use plastic crosses, which are placed in the corners of the tiles.

When laying tiles, it is important to achieve a result without flaws. Therefore, it is best to use special flexible mixes in the work, ensuring the quality of the laying.

Now that the main work on laying tiles is done, it is necessary to wait until it dries completely. If necessary, you can once again perform grouting of the joints.

Rating of manufacturers

Modern manufacturers of underfloor heating offer potential buyers proven systems with a high quality guarantee and increased service life. Still, when choosing a heating system should be based on the rating of manufacturers.

The most popular of them to date are the following brands:

- German brand Rehau

- Italian manufacturer Valtec

- Finnish brand Uponor

- Another German manufacturer Oventrop

It is important to note that all work on laying tiles is carried out only when the heating system is turned off.

You can see the process of installing the water floor with your own hands in the following video.