How to match tiles and laminate flooring?

Combining two types of flooring in one room is an interesting solution. In this way you can bring a highlight to the interior of the room and divide it into zones. Most often combined laminate and ceramic tiles, which decorate the floor in the kitchen, but such combinations are also used in the hallway and living room. To create a high-quality and aesthetic flooring from different materials, you need to know the subtleties of their docking and proper installation techniques. Despite all the difficulties, to combine tiles and laminate flooring will be in force even a novice master.

Advantages of combining tiles and laminate

The use of several finishing materials in one room at once has a number of advantages, which makes this method of repair quite in demand:

- Creation of a unique interior design. Skilled possession of tools and knowledge of the subtleties of laying tiles and laminate allows you to create an original floor covering in the necessary color scheme.

- Room zoning. The floor finish with different materials can divide the room into several functional zones, for example, into a working and dining area in the case of the kitchen.

- A visual change in space. Through the proper placement of materials and combination of colors can visually change the geometry of the room and its area.

- Practicality. As tiles are durable and easy to care for, they are laid in places where there is an active passage, or an increased risk of surface contamination. For example, in the kitchen is a working area, where directly the preparation of food, in the hallway - an area near the door, where tenants and guests get undressed, and in the living room - the loggia or area near the fireplace. Laminate covers other areas of the floor that are less exposed to stress, because it has a low resistance to abrasion and mechanical stress.

- Reduced financial costs. Ceramic tiles are more expensive than laminate, so partial floor tiling can save on repairs, and at the same time bring a highlight to the interior of the room.

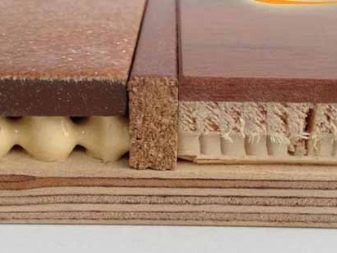

To create a high-quality and aesthetic flooring, you need to carefully select the finishing materials, paying attention to their thickness, color and texture.

Requirement for joints

The location of finishing materials on the floor can be almost any, it is important only to connect them correctly. Formalize the joints between the laminate and tile should be in accordance with the following requirements:

- A level surface. Upholstered floor should not have sharp differences in height, so you need to select finishing materials of equal thickness or use special devices for smoothing the surface.

- Durability. The joints must be watertight, otherwise you will soon have to make repeated repairs. In addition, a connecting material with a long life span should be used.

- Careful preparation of tiles and laminate boards. Depending on how the materials are joined, they must be cut evenly and well, especially if you plan to design shaped joints.

- Aesthetics. The finished floor surface should look like a single whole cloth - for this purpose, the connecting elements should be selected in accordance with the color and texture of the finishing materials.

According to the form of joints can be straight and wavy, but zigzagging connections are not recommended, as they do not look aesthetically pleasing and rude, in addition, in the corners will accumulate dirt. Straight joint is the best option for the connection of ceramic tiles and laminate boards. It is easy to perform, and can be located not only in the center of the room, but also in the doorway. As for the wavy joints, they look more interesting, but the performance of mating materials in this way is quite difficult, and it requires special preparation of finishing materials.

Joining options

There are several ways to combine different floor coverings in a high-quality and beautiful way:

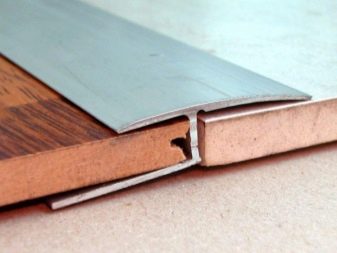

- Threshold. Registration of joints with thresholds, also known as moldings, is the most popular option. Such products are easy to install, disguise uneven cuts of finishing materials and smooth out small differences in height. They can have different shape, size, height, color and texture. Moldings are made of plastic, wood and metal. On sale there are straight and curved products, so you can use them to decorate not only flat joints, but also shaped ones.

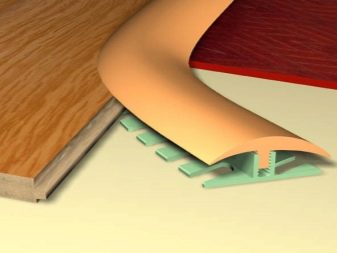

- Flexible profile. The main advantage of flexible profiles is the ability to design joints of almost any shape. The use of such a product is possible only if the height of tiles and laminate is the same. Profiles have different widths and colors, so it is not difficult to choose the best option for aesthetic finishing of the floor.

- butt joint. Floor cladding laminate board and ceramic tile is often made without the use of thresholds. But to lay the materials butt joint, they must have the same height, and they must be carefully prepared. The most difficult to perform is a wavy joint, as the finishing materials must be properly trimmed and neatly sanded.

- Liquid cork. One simple way to decorate the joint between the tiles and laminate - its filling with construction foam, mastic or silicone sealant. This way you can fill the gap of any width and depth. The only disadvantage of liquid cork is the need to dismantle the entire joint if you need even partial repair of the floor. Filling gaps with liquid materials requires skill so as not to stain the laminate and tile, because, otherwise, they will be difficult to clean.

- ПCork expansion joints. Among the most practical ways to design joints include the installation of cork expansion joint. It combines well with ceramic and laminated surfaces, but it can not mask the unevenness of the surfaces, so the finishing materials for the floor must have the same height.

The choice of docking option will depend on the characteristics of the purchased tiles and laminate boards, the shape of the joint, as well as personal preferences.

Types of profiles and thresholds

Elements for the aesthetic combination of different floor coverings are classified according to shape, purpose, material and method of attachment. Products can be straight or curved, and there are also flexible products that create wavy joints. Depending on the purpose, the thresholds and profiles are as follows:

- classic - devices for straight joints between laminate and tiles of the same height;

- levelling - leveling thresholds that compensate for small height differences, and allow you to smooth the transition from laminate to tile as much as possible;

- decorative overlays - Self-adhesive plastic or rubber thresholds;

- finishing - products for masking joints when creating catwalks, or finishing differently tiered surfaces.

Several types of materials are used for profiles and thresholds, which have different performance characteristics.

- Metal. Joint elements are made of aluminum, brass or steel, these materials are durable, strong and resistant to abrasion. The most popular among consumers are aluminum thresholds, they are of high quality and more affordable.

- Plastic. Products made of plastic belong to the budget options, because they do not have a high resistance to wear and tear and durability. Nevertheless, their popularity is quite high, which is due to the good plasticity of the material, and the possibility of designing curved knocks. In addition, this type of thresholds is presented in a wide range of colors, so pick a suitable shade to the flooring will not be difficult.

- Wood. Wooden connecting devices are the most in demand due to their aesthetic appearance. Their cost is significantly higher than similar products, despite the fact that they require special care, including periodic sanding and re-lacquering.

- MDF with laminated coating. Thresholds made of laminated MDF are an excellent substitute for wooden products. They look similar to natural wood, but they are resistant to moisture and do not require special care. In addition, MDF thresholds are affordable, which increases their popularity in the market.

Profiles and thresholds for connecting tile and laminate can have an open and hidden mounting system. The first option is easier to perform, but at the same time the heads of the fasteners are visible on the surface. Hidden system involves fixing products without the use of screws, or their fixation to the inner side of the threshold. Such finishing joints look more aesthetically, but it differs difficult installation, which must begin before laying laminate and tile.

How can you make a joint with your own hands?

Beautiful and high-quality design the joint between the tile and laminate board is possible without the help of a professional master. All that is needed is the possession of construction tools and the exact adherence to the instructions for the installation of materials. The first thing to do is to prepare the subfloor, namely - to remove the old coating and level the surface. If it is planned to create an even joint, then the laying of laminate boards and tiles is made in advance. To create a curvilinear joint, first a profile is installed, then the floor finish is performed, and the materials are trimmed to the shape of the junction line.

Installation of connecting devices, depending on their type, is carried out as follows:

- Metal threshold. The plank already has holes for fasteners, so all that is needed is to measure and cut the necessary length of the product, then install it butt to butt and fasten with screws. Previously in the floor at the level of the existing holes you need to make indentations for dowels. To protect the flooring from moisture, the connecting strip from the back side is treated with silicone.

- Plastic profile. The product is suitable not only for flat, but also for curved joints. Measuring the required length, cut the profile, put it to the joint line, push it to the stop against the tile and mark the place for the fasteners. Drill holes in the floor for dowels, and then attach the lower part of the profile with screws. The upper part of the docking products placed in hot water for 10-15 minutes for his softening, and then connect to the bottom, already attached, part.

- Flexible profile made of metal. In the lower part of the device there are special legs, with which it is attached to the subfloor. Applying the profile to the base, and giving it the desired shape, mark the holes for dowels, and then fasten it with screws. Laying of finishing materials is carried out in accordance with the placed metal profile, while the tiles and laminate boards are cut to the shape of the planned joint.

- Cork expansion joint. The product is selected according to the width and height of the gap between the finishing materials, which, in turn, must be carefully sanded. The sealant should be evenly poured on the bottom of the gap, and only after that the cork expansion joint should be placed, gently pressing it down with a press. When the sealant dries, the excess jointing material should be trimmed, sanded and painted with a special tint. To protect the cork from moisture, it is covered with wax, varnish or oil.

To form high-quality and beautiful joints between tiles and laminate boards, it is necessary to level the subfloor, correctly select materials and carefully prepare them. When performing repairs, there is no need to rush, in addition, it is recommended to think in advance, what will be the joint and make a scheme with measurements.

You will learn more about the rules of docking by watching the following videos.