Film under tile floor heating

Comfort of living in an apartment or private home depends largely on the microclimate in the rooms, so you need to take care of a good heating system. The best modern option is a membrane floor heating, which is perfect for laying tiles. It is a roll material, consisting of a dense base and heating elements. Depending on the type, the membrane floor can be an additional or main source of heat in the room.

Features and Benefits

The popularity of the film floor is due to the presence of a wide list of advantages, which include:

1. High efficiency. Due to high power, the system is able to heat quickly, and the maximum temperature can reach 50оС.

2. Minimal power consumption. The membrane floor consumes a small amount of electricity, which allows you to save in the cold season, eliminating the central heating. In addition, the automatic control system independently turns off when the optimal temperature is reached, but the heated surface of the tiles continues to emit heat.

3. Uniform heating of the room. The film covers 70% of the floor area, so the air warms up much faster, with the highest temperature remaining in the lower part of the room.

4. Affordability. Prices for the film floors have a wide range, so among the wide range of inexpensive materials is not difficult to find. Moreover, you can save money on the services of a master if you install the system yourself.

5. Versatility. Electric underfloor heating is suitable for any flooring, whether it is tile, parquet, laminate or linoleum.

6. Resistance to moisture. Heating cloths can safely be installed in rooms with high humidity - in the toilet, bathroom or kitchen.

7. Safety. Underfloor heating is not dangerous for the people around. They do not emit toxic substances, and do not ignite.

8. Simple installation. Install and connect the system is not difficult, you just need to follow the instructions exactly and follow the recommendations.

Under-floor heating of the film type is most often installed under ceramic tiles, as it has a high degree of thermal conductivity.

Types

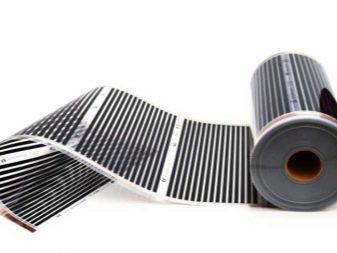

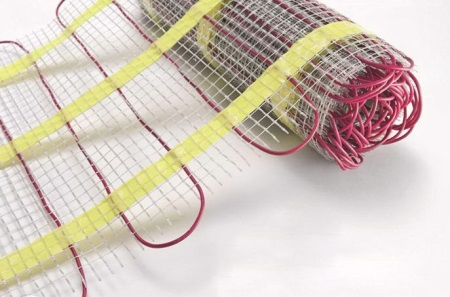

Rolled heating systems, which are installed under the tiles, can be in the form of a thin mat with heating elements, or two soldered films with carbon fiber between them. Both materials are quite effective, but to understand which one is better, you should familiarize yourself with their characteristics.

The carbon fiber model is made of lavsan film, which has high strength, elasticity and wear resistance. In addition, it is dielectric, which indicates its safety. Carbon paste and special additives are used to produce the heating element, i.e. carbon fiber. To increase the strength and durability of heating systems, some manufacturers cover the films with graphite spraying.

The carbon filler is placed in parallel strips and soldered between the two films. Then the products are equipped with conductors made of copper or copper-silver alloy, through which the current will flow to the heating elements, and they, in turn, are equipped with a parallel circuit. This type of film floor is also called infrared. It can be installed in just 2-3 hours, and just as quickly dismantled to move it to another room. The only disadvantage of the system is its high cost.

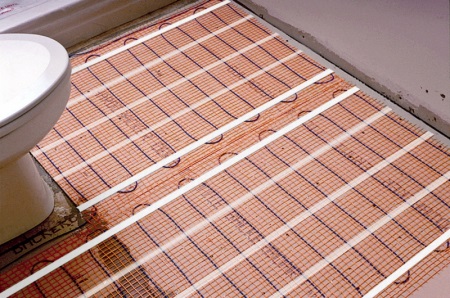

Thin heating mats consists of a heat-resistant mesh and a cable attached to it. The products are equipped with a conductor with a small cross-section, which can be single core unshielded, or double core with protection. This type of film flooring can be installed in a variety of rooms, regardless of their conditions. In addition, the mats will be a good choice for rooms with non-standard configurations, because their mesh base can be cut between the heating cable, and give the products the desired position.

Installation of underfloor heating is performed quickly and easily, because you only need to unroll a thin mat, connect it to the network, and then you can lay the tile. When tiling the floor, a small amount of cement mortar is used, it will be enough not only for gluing tiles, but also for reliable fixation of mats, because the mixture will penetrate through both their cells, and heating wires to the base.

How to choose?

Filmed warm floors, designed for laying tiles, have many similar characteristics, which complicates the choice for consumers. Therefore, in order to determine which system will suit the best, you should pay attention to their differences.

For example, the carbon fiber film has the following features:

- The material can be dismantled and installed in another room;

- Furniture and other objects can be placed directly above the installed system, and they will not interfere with the emission of heat rays;

- the electromagnetic field is practically zero;

- if the heating elements are damaged, the whole system continues to work, except for the failed section;

- can be the main source of heating.

As for the thin mats, their positive differences include only simple installation and affordable cost. Thus, the film with infrared radiation is the best choice. But it should be taken into account that mats for floor heating will be good if there is a main source of heat in the room. In addition, they cost much less than a film with a carbon heating element, which for most consumers is an important selection factor.

Preparatory work

Before the installation of underfloor heating, it is necessary to prepare the base. The first thing to do is to remove all objects from the room and clean it. Then use a level to check for irregularities on the surface. If there is a significant curvature of the floor, then it is better to make a screed, using self-levelling mortar, and in another case, local application of putty will be sufficient.

If the room has a wooden floor without visible damage and rotting, then it can be left, but before installing a membrane floor, it is still recommended to perform scraping. In another case, it is necessary to remove the old coating and perform a concrete screed, or replace it with GFB or plywood.

Another important step is to draw up a scheme of laying the heating material. As a rule, it is placed almost on the entire floor area, retreating from the walls by about 20-30 cm. It is important to remember that when laying thin mats, you should take into account the placement of furniture, because there should not be heating elements under it.

Laying

To install a warm membrane floor, you need to prepare additional tools and materials:

- scissors;

- tape measure;

- hole punch;

- plastic corrugated pipe;

- hammer;

- dowels;

- asphalt tape;

- polyethylene tape;

- reflective tape;

- electrical wiring;

- connecting clips;

- temperature sensor;

- thermostat.

The first thing to do is to determine the location of the thermostat, and then using a hole puncher prepare a small trench in which will be placed the corrugated pipe with electrical wires. Then, in accordance with the scheme, lay a reflective film on the floor, on it, place sheets of heating material, connect them together and install the temperature sensor, and then connect to the thermostat. Finally, the system is covered with polyethylene film, and fastened to the floor with plugs. After that you can start laying the floor tiles. It should be noted that when installing thin mats it is not necessary to use polyethylene film, you can immediately proceed to the finishing of the surface.

Installation

Assemble the foil floor heating can be done independently, it is only necessary to have a little knowledge in the field of electricity. In the case of heating mats, everything is quite simple - the material placed on the floor is already connected by one wire, it only needs to be connected to the thermostat. As for the foil with carbon fibers, its elements should be connected by wires with special clips, and then insulate them with bitumen scotch tape. Additionally connect the temperature sensor, which should be placed near the thermostat on the heating element or under it.

Requirements and recommendations

When installing a warm membrane floor, it is important to observe the following

- It is important to inspect the material for damage;

- Do not bend the membrane;

- Do not touch the heating elements while cutting the products;

- The floor surface must be dry and clean before installation;

- it is not recommended to install a section of the film more than 15 m;

- for convenient replacement of the temperature sensor, it should be placed near the corrugated pipe.

Before you start laying tiles, it is necessary to check the functionality of the system by connecting it to the mains. It is possible that the heating elements are damaged, which will need to be replaced. Turn on the system will be possible after the cement mortar dries.

We suggest that you watch a small video tutorial on the installation of underfloor heating.