Gas water heater water assembly

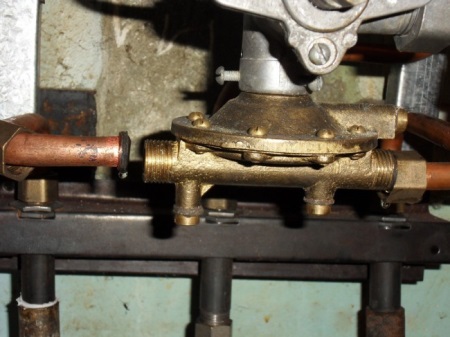

The internal structure of a gas-fired boiler is quite complex and is represented by a lot of parts. One of them is the water unit, which is also called the water reducer, water node, water regulator or "frog". It is located inside the speaker in front of the heat exchanger and is responsible for regulating the operation of the speaker, depending on the flow of water into the unit.

Types

Depending on the material of manufacture, the water block is:

- Brass, that is, made from an alloy of copper and zinc. Brass is often used in the creation of sanitary appliances.

- Plastic. Such a unit is very practical and has a long service life.

- Polyamide. Additional durability of such a unit is provided by the glass fiber present in its composition.

Working Principle

The main task of the water node in the gas heater is to start the heater after opening the faucet, as well as to ensure its normal operation while the faucet is open. Also, this node is important to regulate the flow of incoming water. If the water pressure is insufficient, the reducer will also perform a protective function, preventing the heater from overheating.

The water unit's function is based on the effect of the water flow on the parts of the reducer. The water flowing into the column affects the diaphragm as well as the disc (also called the mushroom). Changing their position affects the stem, which activates the valve of the gas assembly, so that gas starts flowing to the burner.

As soon as the hot water tap is closed, the pressure acting on the diaphragm and the mushroom decreases. This reduces the effect on the gas valve, which cuts off the gas supply and shuts down the appliance. When the gas heater is not turned on, the water assembly does not function.

Design

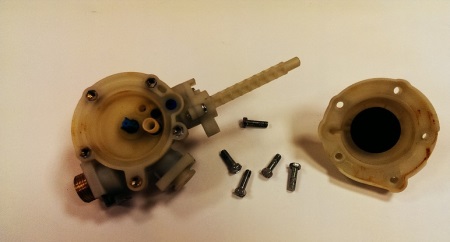

The water reducer consists of:

- A base and cover with screws.

- Diaphragm (diaphragm) with a disk (plate) attached to the stem.

- Flow regulator.

- Venturi nozzle.

- Flow control valve.

- Temperature selector.

- Hot water filter.

The following short videos show the construction of the small and large water assemblies.

Typical malfunctions

Failure of the water unit is considered one of the most common faults in gas water heaters. The most common cause of unit failure is deformation or contamination of the diaphragm. Salts can be deposited on it, and cracks can form. With such damage, the unit stops functioning, which prevents the access of gas to the speaker.

Also quite a common problem is clogging of the water reducer filters, and due to frequent switching on and off of the device, the unit wears out, which leads to leaks in the location of the seals.

You should definitely check the water assembly if:

- The water pressure is normal, but the speaker does not turn on (the diaphragm is damaged or the stem is dirty).

- The cold water pressure is normal but the hot water flow is very weak (clogged).

- The hot water tap is open, but the speaker only starts working after a while (problem with the flow regulator).

- The hot water tap is closed, but the speaker still works for some time (problem with the flow regulator).

- Column shuts down during operation or does not reach the desired power (diaphragm is damaged).

Repair and maintenance

For the gas boiler to function properly, the water unit should be periodically disassembled and cleaned, as well as inspected for timely detection of areas of deformation and small cracks. Replacement of the membrane in the water reducer is recommended even with the slightest deformation of this part.

After disconnecting the heater from the water and gas supply, open the hot water tap to release the pressure. After that, it is necessary to remove the casing of the device and find the water reducer on the cold water pipe. After unscrewing the nuts fixing the part to the pipes and the screws fixing the reducer to the gas assembly, the regulator can be removed.

To open it, unscrew the screws located in a circular pattern that hold the two parts (usually eight). After inspecting the membrane and the housing, perform the required manipulations (cleaning, replacement), after which the unit is assembled and mounted in its place inside the column. It is important not to mix up the connection pipes (inlet diameter must be larger). You should also make sure that all connections are sufficiently sealed.