Why does the gas water heater turns on with a pop and what to do?

Any gas equipment requires very careful handling. This also applies to such familiar household equipment, as a flow-through water heater. After several years of use, users often begin to forget about the basic rules of safety, not to mention regular maintenance and preventive inspection of the device.

Such behavior is extremely irresponsible, since it can lead to serious consequences, including life-threatening ones. Therefore, it is very important to pay attention to any changes in the "behavior" of the gas boiler, especially the appearance of extraneous sounds. Today we will tell you what you should do if you hear a popping sound when you turn on the appliance.

Causes

The problem, which will be discussed in today's article, is most often faced by owners of gas water heaters of older models. Flow-through water heaters of the new model also sometimes turn on with a pop, but with them it happens much less frequently. Clap when turning on is heard because the gas accumulated in the heat exchanger ignites. If the malfunction is more serious, then gas from the heat exchanger penetrates the gas tube and even partially occupies the chimney.

Most often the accumulation of gas occurs for one of the following reasons:

- There is no or very little draft in the chimney;

- The valve that slows the ignition is defective;

- the flame in the ignition wick is deflected to the side (this is relevant for devices with piezor ignition);

If your home has a more modern modification of the gas water heater with the function of automatic ignition, the causes of slamming can be:

- Discharge of energy sources in the control module;

- microswitch in the water unit is defective;

- the spark plug is not positioned correctly.

What to do?

The first thing experts recommend doing is to check the presence and strength of the draft in the chimney. Most flow-through water heaters have a casing, in which there are holes designed specifically for this purpose. If you have not been able to find such holes, try checking the draft near the gap that is under the chimney hood. You can also feel the draught directly in the chimney at the hatch for cleaning.

The draught is usually checked with a lighted match. If the flame deflects well to the side, the draught is normal, if it only flickers, the draught is weak. Fixed flame means no draft - in this case, you can not operate the gas boiler in any case.

New type boilers with automatic ignition

Flow-through gas water heaters equipped with an automatic ignition system are much more economical in terms of gas consumption. They operate under the control of an electronic module that receives commands through micro-switches located on the water and flame controls. Such devices are considered very reliable, but they also have disadvantages, such as costly and complicated repairs.

So, what should you do when you hear a gas explosion?

- Check the condition of the power sources. A "bad" spark, resulting in the fact that the gas does not ignite immediately, may be a consequence of low battery charge. This problem can be solved very easily and does not require the intervention of a craftsman.

- Check the micro water pressure regulator. This device is designed to tell the control module that water is flowing and you need to ignite the gas. The microregulator can break down and give wrong signals if water gets on it. You can diagnose such a malfunction with a multimeter or ohmmeter. If the reading does not correspond to the norms, then the microregulator is broken and should be replaced.

- Check the position of the spark plug. This part can be deformed under the influence of high temperatures or due to temperature fluctuations. It is quite easy to correct its position because it is fixed on a single screw. It is necessary to loosen this screw a little and set the spark plug so that the spark gap is about 0.4-0.5 cm. In this case the ignition should happen at the first attempt.

- Check the condition of the ignition retarder. Gas can build up because the valve that brakes the flow of water is broken or poorly adjusted. The part in question is a small metal ball that partially covers the bypass channel in the water pressure regulator. When in good condition, the ignition retarder should move freely (this can be checked by audibly shaking the cover). If this does not happen, you can try to set the ball in motion by hooking it with a flexible cable passed through the hole in the channel. If the retarder does not yield, you can try to remove it and clean the channel, but it is advised to do this only as a last resort.

- After any repair, all connections should be checked for leaks, and if necessary, sealed with rubber rings or special sealing compounds.

The cost of a micro pressure regulator varies on average from 50 to 200 rubles.

Old type boilers with an ignition wick

Flow-through gas heaters of the old type "pop" quite often. This is due to the peculiarity of their design. They are considered less safe and comfortable than new gas burners, but they are much easier (and cheaper) to repair.

The most common cause of gas accumulation in the cavities of water heaters of this type is the wrong position of the wick for the igniter. In this case, the flame becomes too small, so it cannot reach the edge of the main burner - most often because not enough gas is supplied to the wick. The gas supply may be obstructed because the gas nozzle is clogged.

You can remove the clog yourself, but to do this you will have to disassemble the device. Most of the columns of this type are arranged similarly, so the technical details of repair of different models will differ little. Proceed as follows:

- Block the flow of gas and cold water into the device.

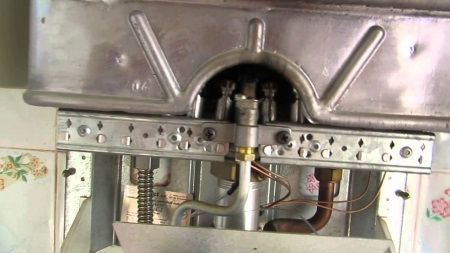

- In order to gain access to the internal structure of the gas water heater, remove the upper casing.

- Find the faucet (tee) of the ignition wick - it is the source of the problem. The tee is needed to mix the air in the gas, while the gas enters it through one tube and the air - through the other. If there is no traction, the top of the water heater accumulates combustion products, which then go into the mixer on the tube, designed for air. Oxygen in this case, of course, almost does not come so the flame can not ignite, and immediately goes out.

- We find the wick guide tube and unscrew the pair of screws fixing it. Next, unscrew the nuts that hold the gas supply and traction sensor tubes.

- Pull the tee out of the groove that holds it in place. If any of the o-rings remain in place - it is not a big deal, if necessary, it can be easily removed.

- In the lower branch pipe there is a gas nozzle (it looks like a small metal screw with a thread). Take out the nozzle from the nozzle.

- Clean the dirt from the hole in the nozzle. For this we need a thin wire. As a rule, after this procedure the gas popping stops. Repeat it monthly or annually - it all depends on the quality of gas you use.

In order to maintain a good technical condition of the gas boiler, we also advise cleaning the nozzles of the main burner at intervals of once every two or three years. It is recommended to clean these elements in the following sequence:

- Unscrew the nut fixing the thermocouple of the solenoid valve.

- Remove the brackets fixing the main burner frame, just loosen a few screws.

- Unscrew the fasteners that connect the gas and water parts of the heater, then unscrew the large nut that regulates the flow of gas from the solenoid valve.

- Bend forward the gas block, pull it out of the grooves and carefully remove it with an upward movement.

- Now we have access to the jets we need. To carry out the cleaning, it is not necessary to remove them from their sockets, we remove impurities without removing the jets from the frame. It is also recommended to clean the burner itself, using an ordinary stiff brush or bottle brush.

Tips

- If turning on the flowing gas water heater is accompanied not only by a pop, but also a change in the color of the flame from blue to yellow, it means that the heat exchanger is clogged with soot and soot. In this case, it is necessary to clean the holes through which the air is supplied to the speaker. This procedure should be carried out only with the participation of an experienced technician.

- If you find any problems in the operation of the gas burner, including popping when switching on, it is better not to take any independent repair measures (except visual inspection), but immediately contact specialized services.

It is recommended to disassemble the device by your own hand only in case of emergency.

The author of the following video tells and shows how else you can solve the problem of noises when igniting the gas boiler.