Design and principle of operation of gas water heaters

Solving the issue of hot water supply in an apartment or house, many people choose to buy a gas water heater. In order not to make a mistake in choosing the right equipment of this type, it is worth knowing how it is designed and how it functions.

The main elements

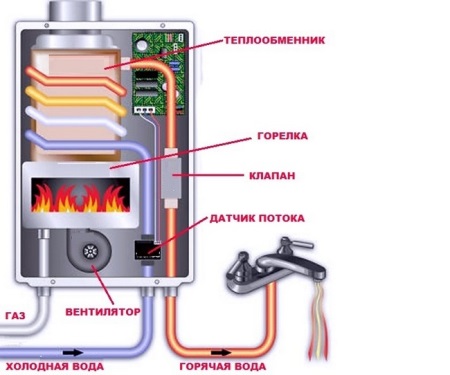

In gas-fired water heaters, there are the following components:

- The main burner. The best option is called the burner, made of steel.

- The system of pipes in which the water circulates (heat exchanger). Usually it is made of copper, but it can also be steel.

- Housing with power and water flow regulators.

- Ignition unit, associated with the ignition burner and power unit.

- Control unit. Some models also have a display on which you can see the parameters of the device.

- Tubes - one for the water supply, the second for the gas supply to the unit and the third for the hot water outlet.

- Diaphragm gas valve.

- Safety System. It includes sensors that actuate in case of lack of water, change in water pressure, overheating of the heater, lack of draught and other dangerous situations.

- Combustion products removal unit (flue gas collector, connection to the chimney, draught sensor). In turbo boilers it includes a fan and a coaxial pipe.

How does the gas water heater work?

Gas water heaters refer to flow-through water heating devices, that is, the water is heated while flowing inside such a device, rather than accumulated in it. Water enters the column through the incoming pipe, then flows through the heat exchanger, which is affected by the heat from the gas burner. As the water moves through the pipes, its temperature rises, resulting in hot water of the desired temperature from the outlet pipe to the faucet. Waste gases are removed from the speaker through the chimney.

The ignition of the main burner in different models of modern speakers can take place in different ways:

- From a piezo element. The user presses a button on the body of the speaker, which causes a spark to ignite the burner. Inside the device, the igniter burns constantly, consuming a small amount of gas. If the ignition burner is switched off, you have to press the button again to act on the piezo element.

- From batteries. This is an electronic ignition method in which normal batteries provide an electric spark to ignite the burner. When the appliance is not in operation, the igniter does not light and no gas is wasted. Batteries should be replaced every 6 to 12 months.

- Hydroturbine. Burner ignition is caused by a spark, in the appearance of which plays the role of a miniature turbine, which begins to work from the flow of water when you turn on the speaker. Such models are very sensitive to low water head.

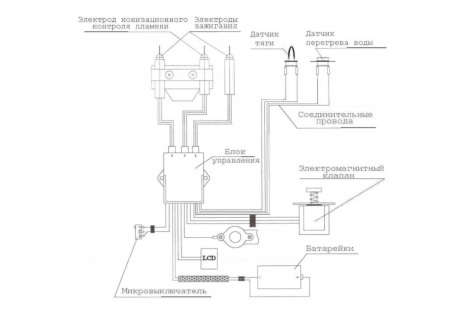

Electrical diagram

An example of the electrical circuit of a gas-fired column is shown in the following figure.

Performance

This parameter is often estimated in liters per minute - in this case, it shows how much hot water the device is able to heat for one minute. In addition, the performance of the unit is directly related to the power of the selected column.

Most often the capacity is estimated by the temperature drop during heating by 25°. For example, if the capacity of your model is 11 liters per minute, it means that for one minute the temperature of the water entering the column in the volume of 11 liters will increase by 25° when it comes out of the hot water tap. Usually when calculating the approximate incoming water temperature choose 10 °, so the water should be heated to 35 °.

To determine the right productivity for your home, you should remember that the approximate flow of water by one faucet is 6 to 7 liters per minute. It turns out, to provide hot water for two points simultaneously (for example, a sink in the kitchen and a shower in the bathroom) requires models of columns with a capacity of at least 13 l/min.

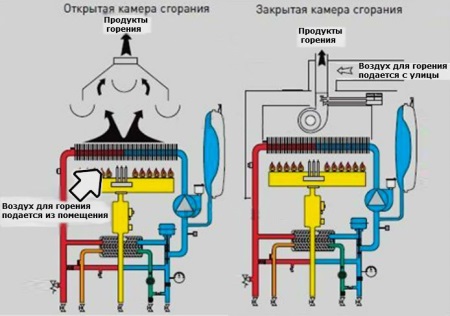

Combustion chamber

In different columns, it can be:

- Open. Such a device operates on a natural draught, drawing air from the room in which it is installed. The exhaust of the combustion products is also due to natural ventilation.

- Closed. It is present in turbine heaters. In such devices there is a fan for forced draft. Exhaust gases are extracted through the coaxial chimney, which also provides an air flow into the speaker from the street.

The gas used

Water heating units most often use natural gas to work, but many of the models can be reconfigured to consume gas in cylinders (liquefied). This is especially true and in demand for hot water to the country or vacation home that is not connected to the gas line.

Gas flow rate

This parameter is directly affected by the power of the device, as well as the possibility of regulating it. You can find out the gas flow rate for the selected model in the certificate on the heater. It is stated in cubic meters of gas per one hour. If you want to calculate how much gas a column with piezo ignition consumes, add about 25%.

Required water pressure

The minimum pressure required to turn on the selected speaker is indicated in the documentation of the equipment. It is especially important to pay attention to this parameter when installing a heater in old houses, built in the 60-70's, as the pressure in their pipes is often insufficient for the heater. If the manufacturer states the minimum pressure requirement of more than 0.15 bar, in an old building with the functioning of the heater may have problems.

Another point - the speaker's ability to withstand the hydraulic shock, which periodically appears during the water supply. This is called a short increase in pressure in the pipes, which can cause leaks and damage to the connections. At a value in the range of 11-12 bar, the speaker is able to withstand such changes.

Power modulation

Choosing a speaker with a modulation option increases the comfort of using such equipment. If there is no modulation, when you open the second tap the water pressure and temperature will decrease, which will affect the performance of the speaker. If there is modulation in the unit, water pressure jumps will cause automatic regulation of the burner power, and the water temperature at the outlet of the speaker will not change.

Note that such modulation has its own limits. Its maximum value is limited by the maximum allowable power of the column, and the minimum is influenced by the features of the water fittings in the device (sensitivity and elasticity). The most optimal range for modulation is called 40-100% of the power.

Features of operation

For a long and effective work of the gas water heater, it is important to observe the following rules:

- Take into account the hardness of the water that goes into the unit. If required, you should take care of its softening and purification.

- Set a comfortable water heating temperature. It is not recommended to heat water too much, as it stimulates excessive scale formation.

- Perform maintenance work on the heater once a year.

In the following video on the example of the Neva Lux 5611 gas water heater model explains the device and the principle of operation of most automatic gas boilers.