The heat exchanger for a gas water heater: why do we need a radiator, how to solder and clean it?

One of the main elements of the gas water heater along with the burner is the heat exchanger. And so problems with this part can worsen the quality of the work of the column or even put the unit out of operation.

Purpose

Such element of a natural gas-fired water heater as a heat exchanger is needed to transfer the heat from the gas burned in the unit to the water flowing inside the metal pipes.

Materials

Steel (different types) and copper are most commonly used to make heat exchangers.

Steel heat exchanger has these features:

- It costs less than copper.

- The material is very plastic, so it tolerates heat well, without changing its physical properties.

- It has a relatively low weight, which positively affects the efficiency of heat transfer.

- It is more resistant to corrosion than aluminum and copper.

The copper heat exchanger has the following properties:

- Thanks to its high heat transfer coefficient, it heats water much faster.

- The fewer impurities, the more expensive such metal will cost.

- Due to the presence of impurities in a low-quality copper heat exchanger, the walls will be heated unevenly, which will eventually lead to their destruction.

- Copper has a high resistance to corrosion.

- To make the part cheaper, many manufacturers resort to a smaller wall thickness and small tube cross-section.

- A copper heat exchanger weighs about 3-3.5 kg.

What is more profitable - repair or replacement?

If you take the cost of a new heat exchanger and work on its replacement, and then compare it to the price of a new speaker, not forgetting the costs of its delivery and installation, it is clearly seen that this repair is more profitable than replacing the entire speaker. On average, a new part costs 3,000-5,000 rubles, and for installation you need to pay about 3,000 rubles. At the same time for a new heater will have to pay from 8000 rubles or more, and then still pay for its connection.

Soldering the heat exchanger of a gas water heater

The duration of operation of the heat exchanger installed in the column is largely influenced by the welding of its pipes. To lengthen the life of the part for soldering is most often used hard solder MF9 (copper-phosphorus). A more modern method of welding, used by advanced companies, is ultrasonic brazing. It heats the structures to be joined evenly, which eliminates the subsequent destruction of the heat exchanger at the soldering points.

Often a gas torch is used for brazing, this process is shown in the following video.

How to remove?

Before dismantling the heat exchanger, the heater must necessarily be disconnected from both gas and water supply. Next, after removing the cover on the body of the device, disconnect the heat exchanger itself by unscrewing the screws securing it, the overheat sensor and the nuts that connect the heat exchanger with the hydraulic group. Now it remains to carefully remove the part from the column.

The dismantling process is clearly shown in the following video.

How to clean?

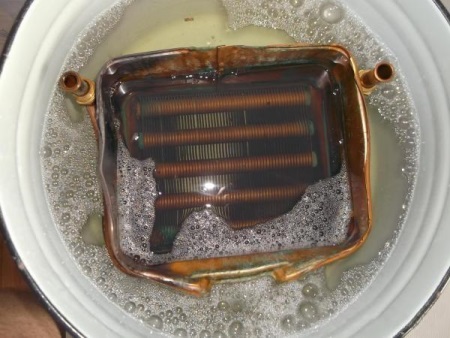

Since over time scaling begins to form and collect inside the heat exchanger, especially if the incoming water is hard and heated to a high temperature, the list of regular maintenance of such equipment includes cleaning from this scaling. It is recommended about once a year, and if the need arises (the column has become worse at heating water), then even more often.

At home, the best choice for cleaning is considered food citric acid, as it is inexpensive and common remedy without a pungent smell. Do not forget about body protection when cleaning the heat exchanger, so in advance prepare gloves and appropriate clothing.

Proceed as follows:

- Dissolve the powder from a large package of citric acid (100 g) in 350-1000 ml of water.

- Carefully pour the solution into the heat exchanger using a funnel, then put the part in a container and leave it for 15-60 minutes.

- For more effective cleaning, you can also heat the container on the stove to +60+80°C.

- Then rinse the part under cold running water, wait until it is completely dry and put the heat exchanger back.

On how to clean the radiator from soot, see the channel "TVorim" on Youtube.