Connection and piping diagrams of indirect water heaters

In order not to have problems with hot water, no sudden shutdowns, interruptions set the boiler indirect heating. In addition to heating water to its functions also includes heating of residential premises. It can be not only a country house, as many believe. Boiler can be installed in an apartment, on the production site. The range of applications is very wide.

But the efficiency of installation of such a system is determined by the strapping scheme, and its installation is not necessary to deal with professionals. Installation and tying can be done by yourself. You just need to understand the complex scheme of tying.

Connection Rules

Indirect heating system - this is another circuit, in addition to the existing one, which produces heating of additional capacity, called boiler. It is fed the most common water from the water supply, which is heated using a coil. In such a system, there is no direct interaction between the coolant and the hot water produced. That is why it is called indirect.

Before proceeding with the installation, it is not superfluous to get acquainted with some rules.

- Water should enter the lower part of the boiler. And the output must be made from the top.

- The circulation of the coolant of such a system should go from the top to the bottom.

If you use these rules, the system will work with maximum efficiency.

The following video clearly shows some options strapping indirect water heater.

Types of piping

Under the strapping of the indirect heating boiler means the connection of the pipelines of the boiler itself with the water supply. The operation of the system as a whole depends on how the installation will be carried out.

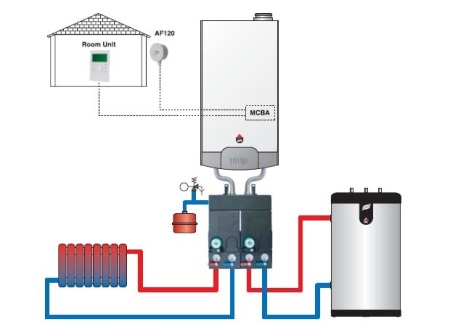

Binding with the servo and three-way control valve

This is the easiest way of strapping. It is used when a large amount of water is consumed.

The boiler is connected to the main circuit and an additional circuit. The first is used to distribute heat to the batteries, the second circuit heats the water in the boiler itself. The three-way distribution valve is connected for competent separation of flows.

The thermostat monitors the temperature of the water in the tank, and when it reaches a predetermined value, a signal is sent to the servo. And it already sends the flow of heated water to the main circuit, for heating. If the water temperature drops again, it will switch in the opposite direction and the coolant returns to the coil.

The most important moment of setting - the temperature set on the thermostat must be set higher than the temperature that is set in the heater! Otherwise, you will not be able to heat the water to the point at which it will switch to the heating circuit.

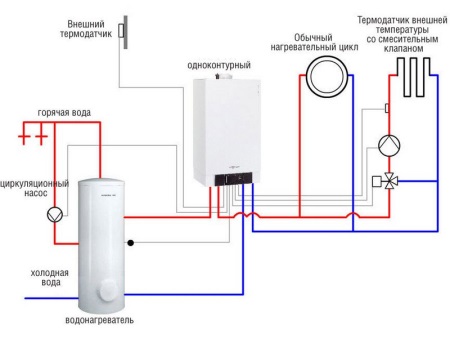

Double pump piping

Another option of piping is to use two pumps in parallel. One is mounted on the heating circuit, the other on the hot water supply. The control of the pumps as in the first case is entrusted to the thermostat. It performs switching of the operating mode.

The quality of heating remains at a high level. The main thing - when fitting two pumps be sure to mount non-return valves at the outlet of each. This is done so that there is no mixing of counter flow inside the coolant.

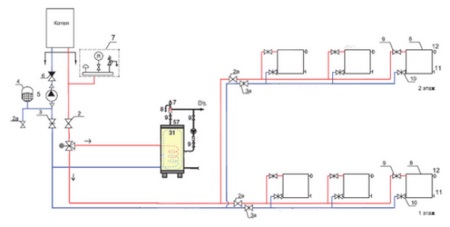

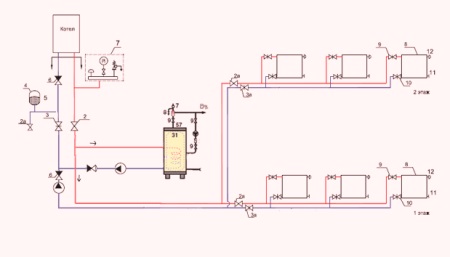

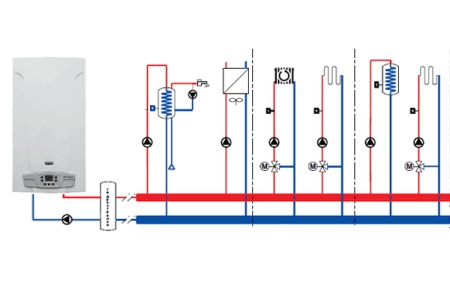

Bundling with a hydraulic arrow

If the heating system has many branches, such as a multi-circuit system of batteries or a separate branch to the underfloor heating, then it makes sense to use this type of strapping. To avoid difficulties with a system in which each of the circuits has its own recirculation pump, a hydraulic distributor is used.

The manifold should balance the pressure in each direction and prevent heat shock. As for this type of piping, there may be difficulties. Therefore, such a task as the installation and subsequent adjustment of such a system is better to trust professionals.

Recirculation of the coolant

In the case where hot water is needed as quickly as possible, then it will be better to apply the recirculation system. Due to the fact that the system is formed in a circular line of coolant. The constant movement of water through it leads to heating. That is why the waiting time for hot water is minimized.

To ensure the continuous movement of water, a recirculation pump is installed in such a system. Such a flow of hot water must be mounted so that it passes through installations that constantly need heating. A floor heating heater is an example of such an appliance.

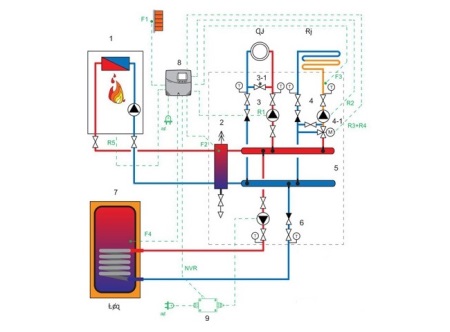

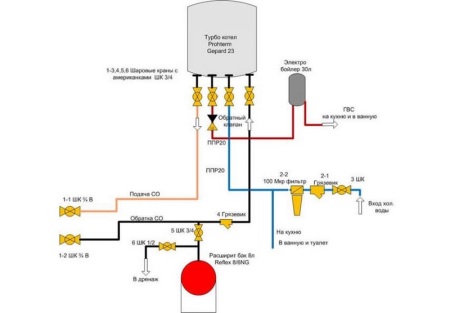

Connecting the boiler to the gas boiler

For the proper functioning of the boiler with a gas boiler, it has a temperature sensor. To make them work together connect the three-way valve. The valve regulates the flow between the main circuit and the DHW circuit.

To a single-circuit gas boiler

For such a connection, piping with two pumps is used. It is able to replace the scheme with a three-way sensor. The main thing is to separate the flows of the coolant. In this case it would be more correct to say about synchronous operation of two circuits.

To the two-circuit gas boiler

The main thing in this connection scheme will be two solenoid valves. The bottom line is this - the boiler is used as a buffer. Cold water comes from the water supply network. The valve for the DHW inlet is closed. If you open it, first the water will come from the buffer, which is the boiler. The buffer contains heated water, the consumption of which is regulated by the capacity of the boiler and the set temperature.

Scheme with the use of a hydrocollector

To balance the flow of heat in systems using multiple circuits, there is a device called a distributor or also called a hydraulic manifold. It allows you to balance the different pressures in the circuits. It can be excluded, but this will cause additional difficulties associated with adding balancing valves to the scheme. And this complicates the installation and adjustment of the entire system.

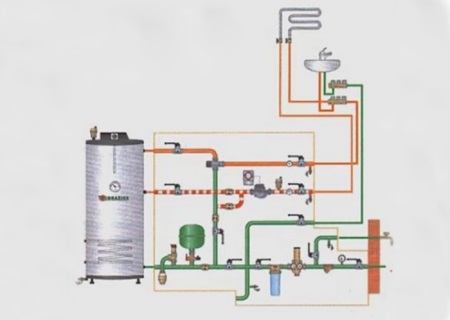

Binding of the solid fuel boiler with a boiler of indirect heating

Connection of the water heater with a solid fuel boiler solves two problems at once:

- getting hot water;

- getting a way to discharge the coolant in case of an accident.

Due to the fact that such a system is placed on the radiator thermostatic valve, increases comfort. But there is a risk of overheating the boiler. The same danger occurs in case of power outage. If a boiler of larger capacity is installed, this process does not pose any danger. Because extra heat is consumed to heat water in the water heating tank. Accordingly, for the normal operation of this system you need a boiler with natural ventilation.

One of the options for strapping a solid fuel boiler with a boiler, see the following video.

Frequent installation mistakes

When installing or in the process of adjustment, you should try to avoid a number of mistakes:

- Boiler and boiler are installed far from each other. Their installation should be made not only as close to each other as possible. But, and to simplify the installation, properly aligned sockets.

- Incorrect connection of the pipeline with the heating medium.

- Improper installation of the circulating pump.

Competent installation, adjustment and tuning will guarantee a stable hot water supply and allow all systems and appliances to work normally. Which will prevent wear and tear parts and save on premature repairs.