Safety valve for boiler

It is very important to follow all recommended safety precautions when operating any piece of heating equipment. This applies not only to large units used in construction or production, but also to compact units such as domestic water heaters.

If you ignore the safety rules, the consequences can be very serious - it is not only about your life, but also about the lives of those around you. Safety valve - this is a very important thing in the home water heater equipment, which, unfortunately, many people forget about. In this article, we will tell you about what this device is needed for, how it works, as well as how to operate it properly.

Purpose

To understand the purpose of the safety valve, to begin with, let's remember elementary things from school physics course. It is known that water tends to increase in volume when heated. If you heat water up to 80 degrees (the approximate maximum temperature of hot tap water), its volume will increase by 2 or 3% - it depends on what temperature was at the beginning of heating.

Since the vessel in which the water is heated in the boiler is sealed, the strong heating inevitably increases the pressure inside the vessel. The result of an uncontrolled increase in pressure can be an explosion of the device. This is where the safety valve comes to our rescue. It performs the following functions:

- prevents hot water from flowing back into the water pipes;

- normalizes the pressure inside the water heater, minimizing the probability of water hammer;

- gets rid of excess water by discharging it as soon as it exceeds normal pressure and temperature values;

- Allows water to be safely drained from the boiler for maintenance purposes.

If you are faced with the question whether to install a safety valve on the boiler, we offer you a video Gennady Myagkov, in which he explains why and when it is necessary to put a valve and how it is designed.

Device and principle of operation

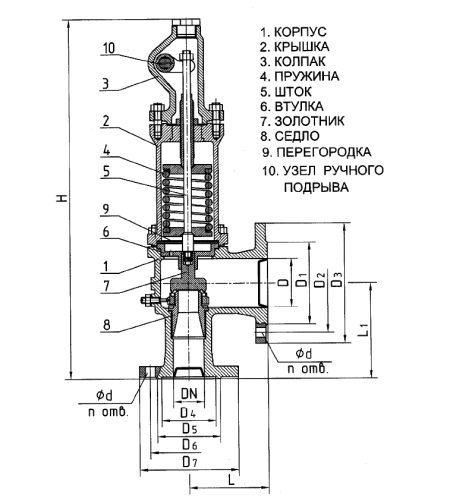

Despite the rather wide functionality, the safety valve has a very simple device: its main elements are two cylinders - large and small.

- The large cylinder represents a kind of "check valve". Inside it there is a flap, which is called a "disc valve". This valve is actuated by a small spring. On both ends of the large cylinder are fixed threaded parts, which are needed to connect the safety valve with other elements of the boiler.

- The small cylinder is fixed perpendicular to the large cylinder. Both ends are plugged and there is a drainage tube on the body. There is also a check valve inside the small cylinder, which works in the opposite direction to the first cylinder.

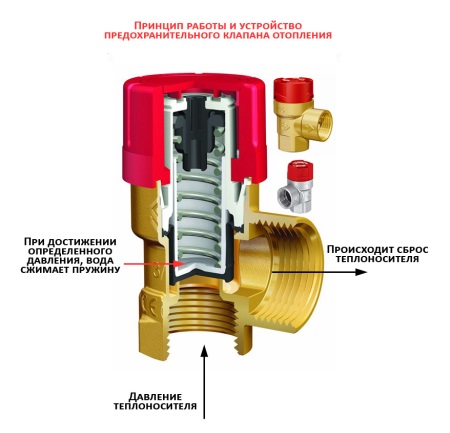

How does the safety valve work? An increase in water pressure inside the boiler actuates the check valve spring. It opens, allowing water to fill the tank. Once the water reaches the desired level, the pressure inside the water heater increases and the check valve slams shut. As the water in the tank is used up, it will be replenished automatically.

The check valve inside the small cylinder is designed for higher pressure. As soon as this becomes critical, a spring is actuated to open the valve. In this way, the excess water will be discharged.

Types

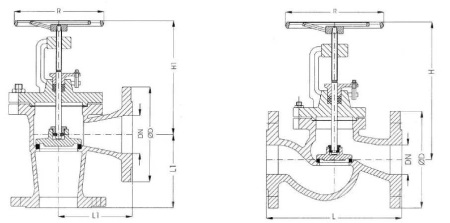

There are several different modifications of check valves for boilers. They differ according to certain key parameters. For example, according to the method of installation, check valves are divided into:

- non-return check valves;

- receivers;

- steel;

- ball valves.

Depending on the principle of operation the following varieties of check valves can be distinguished:

- direct;

- indirect;

- two-position check valves;

- proportional.

Finally, there are several other types of check valves for boilers according to the height of the lift of the shutter:

- full-lift;

- medium lift;

- low lift.

With a release handle.

One of the most common options for check valves, which are equipped with water heaters, is a valve with a release handle. Let's tell briefly about its device and principle of operation.

In the design of the check valve with the descent knob there are the following elements: the body, the fitting for water discharge, the handle of forced pressure release, the spring of the safety valve and the check valve spring.

Water pressure causes the check valve spring to compress, causing the poppet valve to rotate and allow water to enter the tank. After enough water has been drawn in, the check valve returns to its original position.

The release knob is used to release the pressure inside the system by force if necessary. As soon as the pressure exceeds the permissible maximum, the safety valve is actuated, through which the excess water is discharged, thereby normalizing the pressure.

For an indirect water heater

Many apartments are equipped with indirect water heaters. Indirect heating occurs not in the boiler itself, but in another device, most often - a heating boiler. Thus, the work of the indirect water heater and the boiler are closely related. For this type of water heaters, it is required to choose a suitable safety valve.

All the characteristics we need are listed in the technical data sheet of the device, so before buying, be sure to study this document. It is important to know the permissible operating pressure of the device - it is necessary to be guided by it, not by the pressure in the water pipes.

Can the safety valve be replaced by the return valve?

Users of domestic water heaters often ask the question: "Is it possible to install a return valve instead of a safety valve? Technically it is possible, but do not do so in any case. If you make such a replacement, the boiler will turn into a balloon, which at any time can burst.

For example, when the water is heated to 150 degrees the boiler can easily withstand the rapidly increasing pressure. However, if at that moment you open the tap with hot water, the pressure inside the water tank will begin to drop rapidly. Then the boiling point will drop to 100 degrees, but it will not have time to cool so quickly. As a result, the water will instantly boil, a huge amount of steam will be released, the pressure will jump up and there will be a fairly strong explosion.

Selection tips

When choosing a safety valve for the domestic water heater, use the recommendations that were made for you by experts.

- Among the variety of designs, the most reliable is the spring mechanism, as it is able to resist the water pressure well.

- Do not forget about such a factor as the flow capacity of the valve. We advise you to give preference to the device of low or full lift.

- Take into account the arrangement of the water and sewage systems in your home. If the excess fluid will be discharged into the atmosphere, choose an open safety valve, but if in a specially equipped pipe, choose a closed one.

- When choosing a safety valve, you should keep in mind the maximum allowable pressure in the water heater system. If it will be higher than indicated in the certificate of the device, the valve will not be able to function properly.

Functional check

At home it is quite easy to find out if the safety valve installed on the water heater is working. To do this, you only need to set the temperature regulator to the maximum value, and open the tap with hot water. If after the water in the water heater heats to the desired temperature, the excess liquid begins to flow out through the safety valve, then it is quite suitable for operation. If water does not flow through the valve, it is most likely faulty.

How to fix it?

Most safety valves are designed so that once installed, they can not (and do not need to) be adjusted. However, there are some models that need to be adjusted from time to time. First of all, this applies to devices equipped with an adjustment screw, which is able to set the pressure force on the spring and, consequently, the threshold value of the valve actuation.

Before beginning adjustment, carefully read the valve performance data in the accompanying documents. Knowing the operating pressure, you can set the correct screw position.

Installation

We have compiled for you a brief instruction that will help you yourself to install the safety valve for a domestic water heater.

- We disconnect the boiler from the power grid and drain all the water from the tank.

- Find the material that we will use as a sealant for joints (such as ordinary oakum or FUM tape).

- Armed with a wrench, screw the valve into the connection between the water pipe and the boiler.

- Make sure that the valve is installed in the correct position. The direction of water flow should coincide with the marking on the device in the form of an arrow.

Rules of operation

- Do not install locking mechanisms in the area between the safety valve and the boiler inlet.

- The safety valve must be secured no more than 2 meters from the water heater inlet.

- The use of a flexible drain tube made of transparent material will allow you to check if the safety valve is working properly with just a visual inspection.