Indirect heating boilers

Availability of hot water, no doubt, increases the comfort of life of modern man. And if in a city apartment hot water is easy to get, it is enough just to open a tap, for private houses it is often a problem. To provide households with warm water, use different heating devices. One of them is an indirect heating boiler, working in tandem with the heating system of the building.

Pros

- This variant of the heater is the most optimal in the presence of a single-circuit boiler, working on natural gas or solid fuel.

- Thanks to its installation, the occupants of the house can get heated water in large quantities without interruption. In this case, the warm water will go to several points at once.

- Such a boiler does not have a load on the power grid and saves electricity.

- With a large area of the heat exchanger and high boiler capacity, the performance of such a boiler is quite large.

- Water from the heating system is not in contact with the water coming from the boiler for sanitary purposes. The heat exchanger circulates water with a minimum amount of salts.

- Boiler, functioning on the principle of indirect heating, can use for their work in addition to the gas boiler and other sources of energy.

Cons

- The equipment has a rather high price, if you compare with conventional storage devices.

- Such a boiler, especially if it has a large capacity, takes up a lot of space.

- When a large volume of water is heated in the boiler, the temperature of the heating medium in the heating system decreases slightly.

- Installation of the device is disadvantageous if the house is heated with an electric boiler, as well as in the case of low water consumption.

Comparison with other types of heaters

Unlike a two-circuit boiler, the combination of a boiler with a single-circuit boiler, although it is more expensive, but provides a supply of water without changing the temperature and interruptions.

While the flow heater can supply water to only 1-2 points of water withdrawal, the device with indirect heating is much more productive and can provide heated water for the whole house.

In addition, the water temperature from the flow device can be unstable, for example, if you turn on the dishwashing tap and shower in the bathroom at the same time. As for the differences from storage boilers, the indirect heating device is distinguished not only by greater productivity, but also by a lower consumption of electricity.

The principle of operation

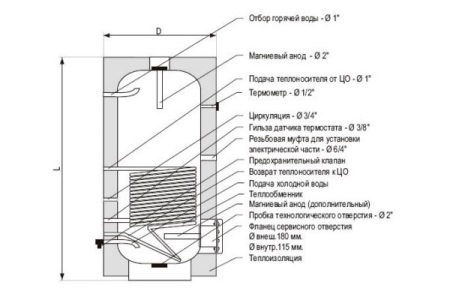

Heating of the incoming cold water inside the boiler is based on the principle of heat transfer. Located inside the tank heat exchanger flows hot water, which heats single-circuit boiler or other energy source. The heat from this coolant is transferred through the walls of the heat exchanger to the cold water, which enters the unit from the water supply. It is gradually heated and removed from the boiler through the outlet pipe.

About the structure of indirect heating boilers see in the video on Youtube channel "vitaly luzhetsky".

Characteristics

Buying an indirect heating boiler, the following parameters of this equipment are taken into account:

- Volume. It is selected depending on the needs of the family.

- Type of installation. Some models of boilers can be hung on the wall, others are installed on the floor.

- Dimensions and weight. They are important to consider for the selection of the place in which the equipment will be installed.

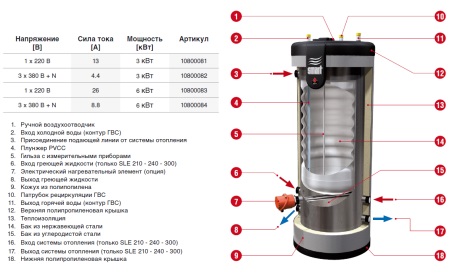

- The presence of the heating element and its power. The heater is needed to use the boiler in the off-heating season, and its power affects the speed of water heating.

Types

With a single spiral-shaped heat exchanger

Inside such a boiler there is a single heat exchanger, represented by a spiral. It can either be located at the bottom of the heater tank or it can be evenly spaced inside the tank.

The "tank-in-tank" type device

In such a boiler there is no coil, because it is replaced by a slightly smaller container installed inside the tank. This tank receives cold water, and in its surrounding cavity circulates water heated in the heating system, which transfers its heat to it.

With two heat exchangers

The design of such models provides two tubular heat exchangers. One of them is connected to the boiler and takes the coolant from it, and the second can be connected to some other heat sources, such as a solar collector.

Well-known manufacturers

Drazice

Brand from the Czech Republic, which produces boilers for over 60 years. The inside walls of the tank of devices from Drazice are covered with enameled glaze. The line of models of this manufacturer includes both floor-standing and wall-mounted horizontal boilers. They are reliable and ergonomic, their design is pleasing to the eye and their dimensions are compact.

Protherm

Brand from Slovakia, the products of which are very popular in our market. Inside the boilers of such manufacturer is covered with protective enamel. Among the range of Protherm there are both wall-mounted and floor apparatuses with indirect heating.

ACV

Is a Belgian brand that offers wall-mounted boilers with a capacity from 100 to 240 liters and floor models with a capacity of 130-300 liters. The advantages of products from ACV is a reduced heat loss due to the 50mm insulation made of polyurethane, as well as high-quality body, the availability of protection against overheating and the possibility of connecting a heating element or heat pump.

Baxi

Brand from Italy, the products of which are in demand in 70 countries. The company produces wall-hung boilers, and floor units with indirect heating of 100-300 liters. The tank in Baxi equipment is made of stainless steel. All boilers have safety sensors to monitor the operation of the device and the level of water heating.

Valliant

Brand from Germany, which produces equipment for water heating for over 130 years. Boilers with indirect heating of this manufacturer are represented by wall-mounted devices, as well as rectangular and cylindrical floor models with a capacity from 115 to 500 liters.

Bosch

A German brand, known for its quality. Its indirect heating apparatuses have an attractive design, the volume from 120 to 500 liters, an internal enamel coating of the tank, the possibility of connecting a heating element and different ways of installation.

Thermex

The Italian brand, which has been producing water heaters for more than 60 years and is constantly introducing new technologies. In the range of this manufacturer has boilers of different volume. On the inside they are covered with bio glass. The advantages of these boilers are also the presence of a recirculation spigot, two magnesium anodes, high-density thermal insulation, and a heating element.

Popular sizes and prices

100 liters

Boilers of this capacity are very common and most often purchased when there are 2-3 people in the family. Water from such equipment enough and for washing dishes, and the daily shower for all the household. If one of the family wants to take a bath, the water is enough for only one person, but will remain for other household needs, and for the second bath will not be enough.

Devices with this volume cost from 11 thousand rubles. For example, a boiler of 100 liters from Gorenje costs 11-20 thousand rubles for the unit from Drazice need to pay 26-37 thousand rubles, equipment from Protherm will cost 20-30 thousand rubles, a boiler brand ACV is about 39-40 thousand rubles, a product of Vaillant 120 liters of volume costs 30-50 thousand rubles, and for a boiler from BAXI should pay 43-53 thousand rubles.

150 liters

This is one of the most popular volumes when buying a boiler of indirect heating. Water from such a device is quite enough to provide a family of 4 people. Such volume is sufficient to wash, wash dishes and take both showers and baths.

Boilers with such a capacity cost at least 15000 rubles. For the device from Gorenje you need to pay 15-25 thousand rubles, boiler from Drazice for 160 liters costs 30-40 thousand rubles, a boiler from Vaillant will cost 50-100 thousand rubles, the device production of BAXI costs about 46 thousand rubles.

200 liters

This volume of boiler is enough to supply a private house with 4 or more people. Water from such equipment will be enough for several bathrooms, as well as for kitchen needs. All family members can wash hands and dishes, take a shower or bath.

Devices with this volume cost from 20,000 rubles. Boiler from Gorenje costs 20-29 thousand rubles, for a device from Drazice need to pay 33-58 thousand rubles, the equipment for 200 liters from Protherm will cost an average of 42 thousand rubles, for a boiler of this volume brand Vaillant should pay 39-66 thousand rubles, and for a similar boiler from the brand ACV need on average pay 47000 rubles.

300 liters

Equipment with such a volume is in demand for large houses, where several families live. Water from this boiler is enough for all household needs. With such a heater, all household members can wash and wash dishes without any restrictions, and do not have to choose between a shower or a bath,

Boilers with a similar capacity cost at least 48000 rubles. For the device at 300 liters from Drazice need to pay 60-90 thousand rubles, equipment of such volume from Vaillant costs from 62 to 120-125 thousand rubles, the apparatus brand Protherm costs about 48 thousand rubles, and for 300 liters of equipment from BAXI need to pay 66000 rubles.

With an electric heater

Boiler, which, in addition to being connected to the heating circuit, is equipped with a heating element, is called combined. Such a device works all year round, and in the winter time the coolant enters it from the heating boiler, and in the summer the water is heated by the heating element, as in the usual storage device.

The power of such a heating element is 2-6 kW. Its inclusion is regulated by the thermostat, when the device detects a decrease in water temperature inside the tank. Some models have a timer for turning on the heating element, which allows you to save electricity.

Selection tips

The first question that is important to decide when choosing an appliance with indirect heating is the necessary volume of the boiler.

To calculate the required capacity of the device, you need to know that one person spends per day:

- for washing - about 5-15 liters of water;

- for showering - about 60-90 liters;

- for bathing - from 160 to 200 liters.

- To wash the dishes - on average 20-25 liters.

Do not forget that in the boiler will be water with a temperature of 80-90 °, and in the process of using it will be mixed with cold, so the flow of water from the device will be almost half as much. By counting the number of household members and rounding up the figure, you will get the right volume of the device.

The next question about the choice of boiler should concern the place of its installation. It will have to take into account the capacity of the device, because devices with a volume of over 200 liters are usually represented by floor models.

Wall-mounted boiler can be:

- vertical;

- horizontal.

When choosing a manufacturer, it is best to buy a boiler of the same brand whose heating equipment you have installed. In this case there will be no problems with the installation work.

It is important to pay attention to the materials from which the parts of the boiler are made:

- Stainless steel tank is a little more expensive, but has a longer service than units with a tank of steel coated with enamel. A good alternative to stainless steel is a tank coated internally with vitrified clay.

- For insulation, which is located in the unit between the tank and the body, in cheaper boilers use foam rubber, and in models more expensive - polyurethane.

- For the manufacture of the body use steel, stainless steel and plastic. The last two options are more resistant to external influences, so boilers with such a body last longer.

- The heat exchanger pipe comes in steel and brass. The steel coil is usually welded to the tank, and the brass part is more expensive, but can be removed for cleaning.

Installation

Detail wiring and types of bundling of boilers of carpet heating Were discussed in another article.

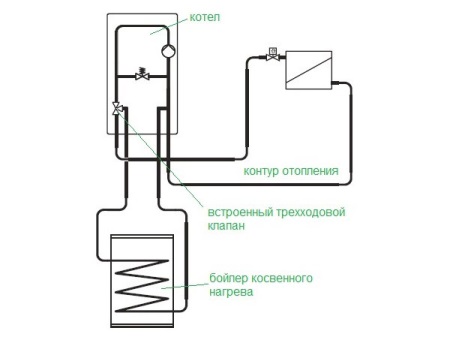

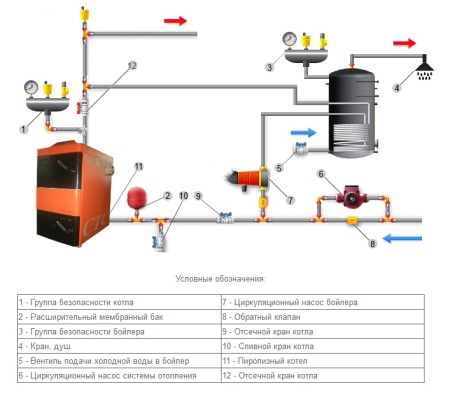

Most often, the installation of the boiler is performed using two circuits - one for heating and the second for hot water. To regulate the heating, in this case uses the three-code valve and the thermostat. If the temperature in the boiler drops, the valve redirects the coolant to the boiler, and after reaching the desired water temperature the main flow of the coolant is sent to the heating system.

In addition, it is often recommended to connect the boiler to the heating system as a parallel circuit with the inclusion of an independent circulation pump. Such a connection will make the unit independent from the heating system and allow you to completely disconnect from the heating circuit if necessary.

The installation diagram and recommendations on the order of installation should be seen in the data sheet supplied with the appliance. First connect the cold water supply to the boiler tank, then install the part responsible for hot water outlet. If you decide to buy a wall-mounted model, its installation should be raised to such a height that the top of the boiler was below the bottom of the boiler.

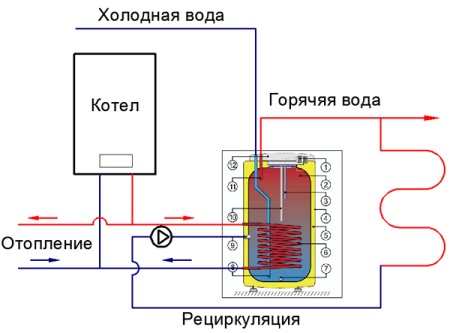

With recirculation

Some models of boilers have the ability to connect a recirculation line, which will allow hot water to flow instantly, and the need to pre-drain the cold water will not be necessary. In addition, it will be possible to install a towel warmer.

It is important to note that such a scheme is only suitable for a looped line, in which water is constantly flowing. In addition, for the recirculation loop, you must install a circulation pump. It is also necessary to install an expansion tank and a safety valve.

See the following video on Youtube channel "Termostar Valentine" for the little tricks of connecting a carpet heater.

Maintenance

Inside the indirect water heater there is a magnesium anode to protect the tank and internal elements of the device from corrosion. It should be replaced regularly, because it "eats away". Instead of such anode you can resort to the use of cathodic protection, but to do this the boiler must be permanently connected to the mains.

Twice a year (before the heating season and immediately after its end) it is important to perform preventive maintenance of the device. Manufacturers recommend contacting a service center for this purpose, but you can determine the degree of contamination of the heat exchanger with limescale, as well as perform its cleaning yourself.

To do this, measure the temperature of the coolant at the inlet to the unit, as well as at the outlet of the unit. If it differs by more than 15°, it indicates normal heat transfer inside the unit. If the temperature difference is 12-14°, the heat transfer is hampered by a layer of limescale.

With such a difference, a "heat shock" will help remove limescale - after draining the water from the appliance, run a coolant into its heat exchanger for ten minutes, then fill the boiler with cold water, resulting in a large temperature difference between the heated heat exchanger and the water that will surround it. This will cause lime scale to come off the tube, after which the tank should be flushed.

If the temperature difference between the incoming and outgoing coolant will be less than 12 °, it is a sign of a very large layer of scale, which requires special chemicals to remove. According to the manufacturer's recommendations, they are diluted in water, poured into the boiler and wait the required time, then rinse twice with cold water.

Is it possible to do with your own hands?

Creating a boiler of indirect heating with their own hands is quite a real task. For such a homemade device you need:

- Select a suitable tank, which will serve as a tank and body. Often such a tank is chosen from an old washing machine. Also a suitable option would be a plastic barrel or can holding 100-150 liters.

- Make a coil of the heat exchanger. To do this, you can bend a copper pipe of suitable length.

- Purchase fittings, valves, check valves, couplings and fittings.

- Insulate the device to increase its efficiency. For this purpose, mineral wool and foil insulation material is most often used.