Boiler Safety Group

When installing a boiler in a residential building, it is necessary to pay great attention to the safety of its use. It is important to remember that this device at one time there is a significant volume of water with a very high temperature. To the walls of the boiler is not affected by too high pressure, resulting in the heated water leaks from the device, in such equipment has special parts, called the safety group.

Purpose

The main function of the safety group of water heaters is to ensure the right pressure in the system and control it. Thanks to such equipment, it is possible to urgently release the pressure when it exceeds the maximum allowable parameters.

Composition

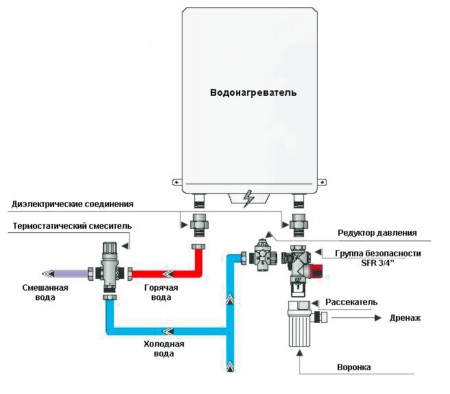

The elements of the water heater safety group include:

- Excess pressure valve, which is also called a safety valve.

- Check valve, which prevents the return of water from the boiler to the water system.

- Shut-off (stop) valve.

- Adapter through which flexible hoses are connected.

These components can be installed separately or presented together in one body.

In large volume boilers can be installed hydroaccumulator.

Types

Buying a safety group for a boiler, you can choose among these options:

- OSO equipment. The set OSO KV, designed for pressure up to 9 bar, includes a special shut-off valve and a special redundant valve that acts as a non-return and safety valve. In the set OSO BS there is a valve that acts as a thermal mixing and non-return device. Hot water is diverted from the spigot located at the top of the equipment. Such a safety group can be installed in case you use multiple boilers.

- Equipment Watts. Designed for pressure of 7 atmospheres, in the package has a guide for drainage. The advantages of such safety groups are high reliability, good quality and affordable cost.

- SYR equipment. Such equipment is designed for pressure of 6-10 bar, depending on the model. SYR 330 DN set is able to withstand temperatures up to +95ºC. The SYR 24 DN and SYR 25 DN kits are soundproofed to class 1 and include a backflow prevention system, safety valve and shut-off valve as well as a pressure reducer and an expandable drain funnel. The equipment is made of pressed brass.

- SDM GB kit. This safety group optimally protects closed circuit heaters. The single compact casing contains non-return valve, safety valve and shut-off valve. The set can be installed on a heater with a capacity of 200 to 3000 liters. It is able to effectively protect the boiler from hydraulic overload, withstanding a pressure of 6-10 bar.

- ACV 10800102 kit. Its use speeds up installation and start-up of the boiler, as this set includes not only a safety group, but also a special mixing valve, and other specialized parts for the installation of the heater.

Application

A safety valve is mandatory on any storage water heater, and if the safety group on the appliance is missing, it immediately voids the warranty. When the valve trips, it causes a small amount of water to be released, which reduces the pressure in the system. Valve actuation pressure settings are usually fixed and set by the manufacturer. They also include a manual pressure release option.

Installation and Mounting

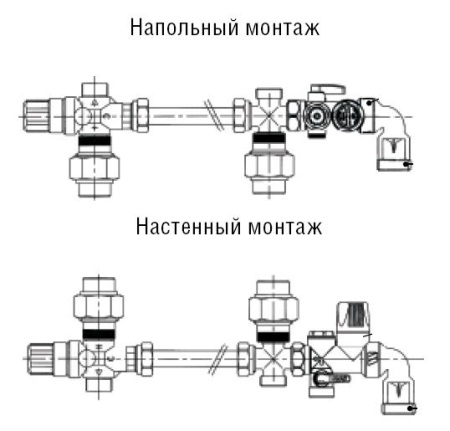

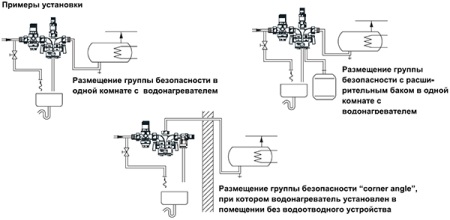

When choosing the right safety group for your boiler, it's important to consider the pressure its safety valve is rated for. In order to effectively protect the unit from overfilling with water, the safety group is mounted on the incoming pipe that carries cold water. In this case, install the parts so that the coolant moves in the direction indicated by the arrow on the body of the safety group.

In the following video you can see how to assemble a store-bought safety valve for a boiler Vaillant.

Safety rules

- It is important to remember that the parts of the safety group are heated, so there is always a risk of burns upon contact with them.

- Regular maintenance of such equipment is recommended, which is carried out in conjunction with the maintenance of the boiler.

Both the installation and maintenance of the safety group should be handled by professionals.