Gas direct heat boiler

For a comfortable stay in the house or apartment it is important to have both cold and warm water. To heat water in the present time in demand appliances of different types, using for their work different energy sources. Since natural gas is one of the available energy resources, boilers, working on this fuel, are quite common.

Features

- In a direct-fired gas-fired boiler, the increase in water temperature inside the tank is due to the direct effect of the heat released from the combustion of gas.

- The performance of the gas boiler is quite high.

- Such devices are more economical than electric boilers for direct heating.

- Installation of such a boiler presents some difficulties. First, it is necessary to agree with the regulatory agencies. Secondly, the installation of a gas boiler requires the presence of the chimney.

- According to the method of installation gas boilers can be wall-mounted (such models hold up to 150 liters of water) and floor (more voluminous devices).

It costs a gas boiler is much more than the electric models.

Design and principle of operation

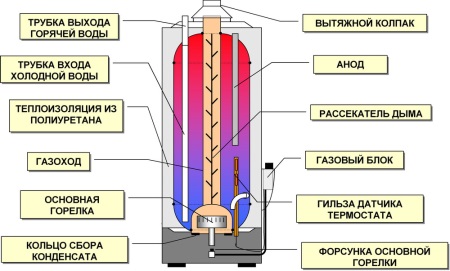

The main element of the gas boiler is a gas burner, located in the combustion chamber under the water tank. From it through the tank of the boiler is a pipe, through which the products of combustion are drained. Heat is transferred to the water in the tank both from the burner itself and from this pipe.

The power of the burner directly affects the productivity and capacity of the boiler. Wall-mounted units usually use gas units with a capacity of up to 5 kW, and floor-mounted units - over 6 kW.

The outer casing and tank of most modern gas boilers are made of metal. It can be both stainless steel and other metal with enamel coating. On the inside, the walls of the storage tank are often treated with a coating that prevents corrosion - glass ceramic, titanium or other.

Between the water tank and the outer casing of gas boilers there is a thermal insulation layer. Its function is to keep the temperature of the water that is heated in the boiler for some time after heating. On the top of the body there is a control unit.

Water enters the tank of a gas boiler through the inlet pipe and is extracted from the top of the unit through an outlet pipe connected to the hot water tap.

Inside the tank in all boilers there are details such as a magnesium anode (it is needed to protect the walls of the unit from corrosion and must be replaced regularly) and a thermostat (it determines the temperature of the water and regulates the gas supply to the burner to turn it on or off).

In addition, each modern gas boiler has a safety group, which includes a safety valve (it resets the excess pressure), overheat protection, as well as a water sensor. In addition, the safety group of such equipment must necessarily have a sensor that determines the draft in the chimney.