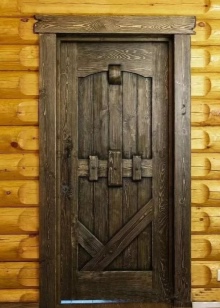

Choosing wooden doors for the sauna

What are the pros and cons of wooden doors in the bath? What are the characteristics of products made of Caucasian lime and aspen? Are carved solid wood doors topical? What sizes of entrance doors are considered average? When building your own bathhouse, it is necessary to pay attention to every component. Doors for the steam room must have certain technical characteristics. Despite the rich range of glass models, wood products remain at the peak of popularity.

Advantages and disadvantages

Wooden doors to the bath have the following advantages.

- Solid wood is a natural and completely safe material for health and the environment.

- The wood has an original and expressive pattern. It is also worth noting the high aesthetic qualities of raw materials. Each grade has a characteristic pattern.

- Products made of wood fit harmoniously into the decor of the bath. Such an element will complement the overall composition.

- The material is treated so that it is not afraid of high temperatures and moisture.

- Modern manufacturers offer a great variety of doors, made of various types of wood.

- Natural raw materials are easy to handle. Even if the doors are swollen or have changed shape, you can fix it yourself.

There are also disadvantages.

- If the manufacturing technology was violated, the doors will quickly fall into disrepair. Cracks, chips and other defects can appear on the panels.

- Some buyers believe that wood is not practical enough, and opt for glass or plastic options.

Overview of types

Manufacturers offer the following options for doors made of wood for the bath or sauna. Products differ not only in the quality of the material, but also stylistics and other characteristics. Customers can choose from carved models, as well as products in a laconic style.

Solid wood

Solid wood panels are the most common and high-quality option. Natural wood does not emit fumes. Some believe that wood has a strong positive energy that disposes to a comfortable atmosphere.

Modern technology makes it possible to make furniture and doors out of wood, that have a long service life. Manufacturers use special compounds that increase the practicality and durability of fabrics. Due to the fact that the steam rooms are constantly preserved high temperature and humidity, models made of solid cloth are ideal. Special tongue and groove boards are used for manufacturing.

The production process is as follows.

- Boards are placed vertically.

- The main material is securely fastened together with tongue and groove.

- To make the construction more reliable, it is supplemented with a bar, placing it diagonally.

Despite the many positive characteristics, products made of solid wood have a lot of weight.

Of linings

Products made of linings will be great for a blank door. The main The main distinguishing characteristics of such products are the thin slats (maximum thickness up to 22 millimeters). To connect them, manufacturers use studs or grooves. Quality material attracts attention with a presentable appearance and excellent noise insulation. It is also worth noting the environmental friendliness and safety of the linings.

Models used as interior doors are made of euro linings. To divert excess moisture, manufacturers equip them with special gaps (they can be found at the bottom of the product). If you choose the doors from the eurowoods correctly, there will be comfort and coziness in the room.

Combination

Combination options are also in great demand among buyers. In this case, brands offer a duo of wood and glass. In one product they combine the advantages of both materials. Combination models look as follows.

- The frame and the lower part are made of wood.

- The glass insert is placed in the upper part of the door.

A rich assortment offers a choice of shapes as well as colors and textures of glass. Transparent material allows light into the room, and the wooden base has excellent performance characteristics.

Varieties of wood

In the field of production of doors for the bath are used different varieties of natural material. Each of the options has certain technical characteristics and a special appearance.

- Variants made of oak can boast of excellent density and durability. These are options with a long service life. Oak doors have a high cost, which is quite justified.

- Models of linden Are not afraid of high humidity. This variety is resistant to rotting and warping. Under the influence of high temperatures, lime begins to exude a pleasant smell. The wood does not emit resin and you do not have to worry about splinters. Nowadays, you can find Caucasian linden options in almost every catalog.

- Versions of aspen combine affordable cost and optimal performance. When properly used, the cloths retain their integrity and marketable appearance.

- Another long-lasting variety is larch. It is also not afraid of moisture and high temperatures. Manufacturers use special impregnations that protect the cloths from rot and mold.

- Canadian cedar Has special healing properties. When heated, the wood begins to release beneficial substances, without resin. Cedar is not afraid of mold.

All varieties used in the manufacture of doors must have certain properties.

- Excellent fire safety.

- Noise isolation.

- Resistance to moisture and prolonged exposure to high temperatures.

Fittings .

Aside from natural raw materials, door production does not do without special fittings. Most often manufacturers use door handles made of wood. Due to the low thermal conductivity, this material is ideally suited.

Metal elements (handles, latches, locks and much more) are also used. However, they cannot be installed inside the steam room. Also Various latches and locks are forbidden because of the high temperatures inside the room. When placing elements made of metal inside the bath, burns are possible.

When using hinges, the choice is made in favor of products made of brass or other metal alloys. They are covered with special enamel to protect against rust. Also, doors are supplemented with mortise elements.

The nuances of choice

Given the fact that bathhouses remain popular, the demand for doors for steam rooms always remains high. When choosing a model, it is necessary to pay attention to the following characteristics.

- Of great importance is the type of wood. Each option has its own characteristics, with which you need to familiarize yourself before buying.

- Also consider the size of the doors, so that they fit under the doorway.

- If you make a purchase in a stationary store, carefully inspect the product for defects. Quality panels should be free of cracks, chips, knots and other flaws.

- Pay attention to the intended use. Entrance doors will differ from those installed in the interior space. Variants installed from the street may have metal handles. Also, outdoor models are tighter and wider.

- Remember that the bathhouse is a room where there is almost always high humidity and temperature. In the technical specifications you can find information about the maximum level of humidity and temperature that the door will withstand.

- Do not rush to choose the first model that caught your eye. The market offers a wide range of products, with which it is advisable to get acquainted in detail. Compare prices in different stores.

- When ordering doors over the Internet, contact only trusted manufacturers. If you have doubts about the quality of the products you offer, ask for the appropriate certificates.

At the entrance

Entrance door does not have to meet all the requirements of the model for the bath. When choosing such a product, experts recommend to be guided by the maximum preservation of heat. With frequent opening and closing, it is important to maintain the necessary mode inside the room.

As a rule, manufacturers use reduced or standard sizes. Such principles are adhered to in order to minimize heat loss. Non-standard products will have an increased cost.

Also, the size is influenced by the peculiarities of the structure of the room and its size. For example, small doors will look ridiculous in large buildings and vice versa. At the same time, there are standard values. The average width varies from 70 to 80 centimeters. Height - from 1.80 to 2 meters.

Note: some models can be supplemented with insulation.

To the steam room

Doors for the steam room can be smaller in size. Opt for options that open outward. The optimal width is between 55 to 70 centimeters, with a height of 1.50 to 1.70 meters.

When choosing a door for the sauna, you must always When selecting your door for the steam room, you will want to make sure you pay attention to the threshold. Its minimum height should be 15 centimeters. When buying a combined product, the glass insert must have certain technical characteristics. The minimum thickness of the glass is 0.8 centimeters. A special material that is not afraid of shocks and high temperatures is used.

To the washing room

Separately choose doors for the washing room. Despite the fact that in this part of the bath is kept moderate temperature, the level of humidity here remains high. This must be taken into account when choosing doors. In this case, the ideal limeWooden doors are ideal, complemented by inserts of impact-resistant glass.

Doors with a wooden frame of any kind are suitable if the room is fully ventilated.

How to properly insulate?

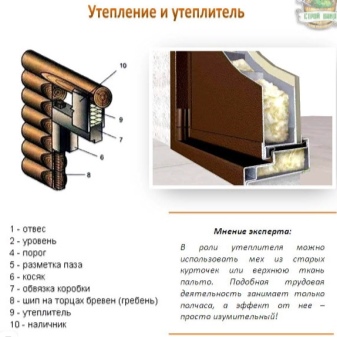

Using a frame.

There are several options for insulating sauna doors. The easiest and most practical way, which you can try on your own, is to attach a frame to the door. It is made from bars, the thickness of which varies from 15 to 20 millimeters. When choosing this method, it should be taken into account that the outer edge of the frame should be placed at a certain distance from the edge of the leaf by a quarter of the dash and another 1 centimeter.

This is not the end of the work. To the additional wooden element you need to add insulation. To fix it, aluminum nails are often used. You can also fill the void that was formed inside the frame.

As insulation, sheets of fiberboard are used. For a clear demonstration, look at the attached image.

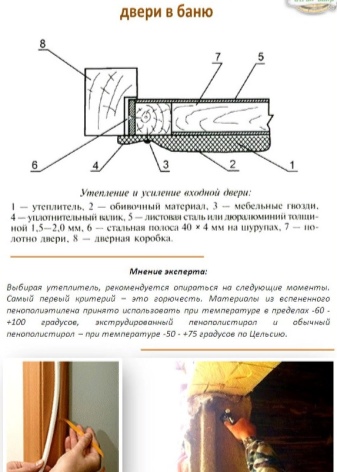

Using energy-flex

This option is recommended to choose for insulating doors in the bath. Press the selected material to the edge of the door, fixing it securely with a stapler. For the door to close without effort, it is not recommended to press the energy-flex hard.

After the construction is completed with metal battens. Despite the fact that the insulation work takes 10 to 20 minutes, the result is a reliable and practical insulation. If necessary, part of the insulation can be quickly replaced with a new one.

Another popular and common option is The use of a thermal curtain. This method is suitable for those who plan to insulate the door without the help of specialists, but do not have the proper experience in this area.

On how to choose a door, see below.