All about finishing baths and saunas

Know everything about finishing baths and saunas is important for owners of country and many urban plots of land. If you understand what and how to decorate the sauna with your own hands, you can create a harmonious atmosphere. In addition to cladding with unedged boards and imitation beams, slabs and OSB plates, there are various other options.

How to decorate the steam room with your own hands?

Conditions in the steam room depend not only on what kind of furnace is installed, how it works. A very important role is played by how properly made the finish inside. Attention will have to pay not only to the appearance, but also the practicality of such decoration. Almost always the walls of the steam room decorate with wood. Only in rare cases use other materials.

Looks quite beautiful design under the log. Optimally solved this problem by decorating with sawn wood or sections of trunks. A very important role is played by the correct impregnation with protective compositions.

Fouling is also relevant - because under the bark gathers a large number of insects, it is unlikely to be pleasant. Manipulating the size and shape of the cuts allows you to decorate the steam room beautifully and originally.

According to many people, it is better to use a log cabin. The steam room will look chic in this version. But the wood will darken over time. Prevent such a situation can be prevented by special treatment of the inner lining - the choice of preparations is very important. Before describing specific solutions, it is necessary to understand the peculiarities of different types of wood.

It is often recommended to finish the steam room with cedar. This wood is praised for its attractive design. The essential oils of cedar are released when heated. Since there are relatively few resins, cedar wood will not burn. The shortened fibers eliminate cracking.

Additionally, it is worth emphasizing such advantages:

- decent appearance;

- excellent relaxation effect;

- excellent maintenance of geometry;

- absence of end cracks.

Lime is often used for finishing saunas - this method is characterized by attractive characteristics. Lime wood is easy to work with and hardly ever dries out. It is soft and quite comfortable. Finally, this wood has a graceful, creamy color that many people like, ranging from brown to white shades. The lime covering of high-temperature rooms is very effective. In favor of this option is evidenced by the lightness. You can do without particularly powerful frames and limit the load on the foundation. The pleasant aroma lingers long after finishing. In skillful hands, lime allows you to decorate the room extremely gracefully.

In some cases, the steam room is decorated with natural stone. Gathered in the mind, perhaps, the image of massive slabs is unequivocally wrong. After all, the same result is easily achieved with the help of small tiles, supplied by a variety of domestic and imported manufacturers. Brick, normal concrete or aerated concrete can be used as the basis. Laying tiles on wood or gypsum fiberboard is carried out only with auxiliary reinforcement.

On large areas, it is advisable to lay a brick base in advance. Primer, including heat-resistant primer, is not used near stoves. Tiles are cut either with diamond saws, or with an automatic cutting machine with a diamond cutting disc.

Additional application of protective compositions, which will allow saving the original color and texture, is useful.

But still much more often it is necessary to finish the steam rooms of baths and saunas with wood in stages. The basic sequence is as follows:

- wiring in the planned places pass in advance through the insulation and waterproofing (if they are already made);

- make purlins;

- install vapor barrier on top of it;

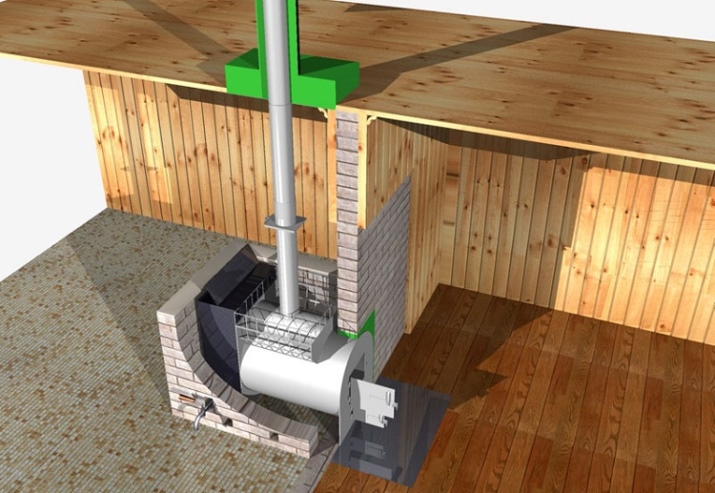

- Outline the area for mounting the furnace - it will be made out according to a special method and a little later;

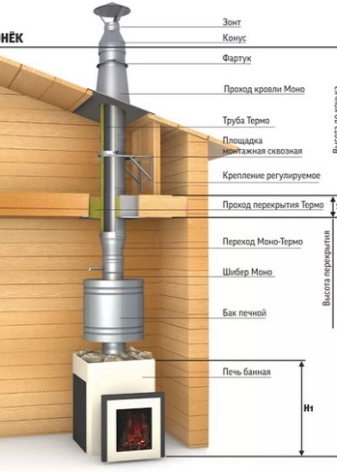

- Make holes for the chimney;

- Place the thermal insulation;

- close it with a vapor barrier membrane;

- form the base and walls for the furnace;

- the floor is made out;

- Put the frame for the door and the door itself;

- paneling the steam room from top to bottom;

- Finish the work by installing shelves, other parts of the sauna equipment and arranging the lighting.

Electric cables can only be used in one piece. Any connections, even terminals or soldering, are inadmissible. All the more so, twisting is prohibited. Attachment points and connections of lighting systems must be properly insulated. You can illuminate ceilings, shelves or corners at your own discretion. Small windows often help to illuminate the steam room during the day.

But because of them the loss of heat is accelerated. That is why you must either make a very small hole, no more than 30x50 cm, or refuse to do this idea at all. Trusses are attached in such a way that is associated with the chosen direction of the lining of battens. The thickness of sheathing must match the thickness of the insulation. It is mandatory to use a vapor barrier membrane, which provides "breathing" insulation.

Chimney ducts are made either in the ceilings or in the walls. Around them form a heat-resistant gasket. Classic steam room can be lined with wood decking. But in a more modern version, tiles are used, which last longer. Continuing the theme of materials, it should be noted that the sauna can be finished with solid alder. It is relatively expensive, but it has excellent quality. The smooth finish will be devoid of defects. The surface will look exquisite and functional.

But many people believe that it is much better to use larch. Its unique pattern and structural strength are the main characteristics that condition such a choice. It is worth noting, however, that larch splits easily. The possibility of damaging it is very high. Finally, it has a relatively high thermal insulation.

Another option - cladding pine, though, it has more disadvantages than advantages.

Finishing the shower room

To decorate the washing area it is quite possible to use unedged board. Despite its apparent simplicity, it looks original and has an aesthetic appearance. Proper stripping and processing is very important. If you do not clean the surface of the bark, you will still have to use protective impregnation and antiseptics. However, such finishing material is better reserved for the facade, and inside it is more correct to use lime decking as a more attractive solution.

Lounges and rest rooms can be trimmed with hardwood and softwood in equal measure. The most in demand are:

- oak;

- pine;

- aspen.

These species are very durable and biologically inert. They are climatically resistant and mechanically strong. Such material looks acceptable on all surfaces and planes. It is also worth emphasizing that for finishing showers, along with wood, you can use:

- tile;

- majolica;

- fiberglass wallpaper;

- natural stone;

- decorative plaster.

The floor is often covered with decking boards - both "deck" and "corduroy". All the difference is related only to the appearance of the surface. In terms of dimensions they are identical. It is best if the board is made of larch. The resins it contains will perfectly stabilize the material and protect it from rotting.

An even more advanced and durable material is thermal wood. It can belong to any species. A special treatment guarantees an almost "stone" hardness and a noble shade. Regardless of the chosen flooring and wall covering, you should carefully calculate the need for it.

It is recommended to use cast waterproofing as an underlayment - it is the most reliable option.

Walls made of wood in the washroom can be protected with special paints and waxes. This alone is enough to double the total time of use. Oil compounds penetrate deeply into the wood and protect it from the inside. Several thin layers will reliably protect the structure from water. In addition to the usual common species, it is sometimes worth using and expensive exotic abasi, which stands out for its original texture.

Black alder serves a long time. Not only that, it is often noted that over time its aroma intensifies. In favor of this solution is evidenced by the absence of the feeling of overheating. However, the usefulness is less than that of linden. Yes, and the cost is noticeably higher.

Among the valuable species for the sink also includes ash. But it:

- Will not darken;

- differs visually elegant texture;

- It is curative in case of respiratory system illnesses.

More expensive than almost all encountered species is Canadian cedar. It is used only in the baths of the elite level. The fragrance of this tree is pleasant. It is not difficult to handle. Another important advantage is the aesthetic appearance. You can save significantly by buying pine or spruce wood. The normal cost of felling from them does not exceed 300-400 rubles per square meter.

For your information: it is also possible to finish pine blockhouse beautifully from the outside. Birch solid wood cannot be used. It is only suitable for dry rooms.

Cladding the room for recreation

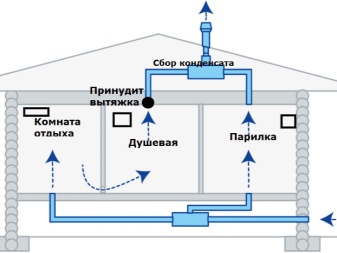

Do not think that the interior of this room is less important. For fire safety reasons, decorative stone is often used there. Aesthetically, it is also quite pleasant. A very important role is to think through the device of ventilation (in this case - the point of exit of ventilation pipes). It is worth remembering that even the rest room is often filled with humid air and steam, so we must use boarding with special impregnation, which blocks the humidity.

The boards themselves are oriented according to your choice - both flat lines and diagonally. Decorating with natural stone is quite expensive. But there is a reliable protection against aggressive influences and even fire. In some cases, moisture-resistant gypsum board is used. Paint or wallpaper is applied on top of it, and decorative plaster is another option.

A modern and very elegant option is the use of photo wallpaper. They are available in a stunning assortment. But again, not all of their options can tolerate a lot of moisture. If it is a serious problem, it is worth looking at the stone wallpaper. In terms of decorativeness, they are at least as good as other options. Alas, using OSB boards in finishing - as opposed to roughing - is not advisable. Even a small emission of toxic substances, meeting the standards, is undesirable. In the case of roughing, the necessary protection is guaranteed by vapor membranes and waterproofing.

But even with their use, you can not make the subfloor of OSB. Prior to finishing, the stone surfaces of the walls are smoothed, and wood is treated with special substances. Trim ceilings are formed from battens, although the moisture-resistant gypsum board is also not bad. Often use stretch ceilings that perfectly fit into any environment. On the floor, only materials that are resistant to abrasion and water ingress are put.

Many experts consider moisture-resistant tiles with minimal slip as the ideal option. Ceramics last a long time, maintaining an attractive appearance.

The problem when using tiles with a pattern is the need for careful pre-layout. It is even useful to take a special photo of such an arrangement, so that it can be harmoniously repeated. Fixing is done either on branded tile adhesives, or on manually prepared cement mortar. The tile markers allow you to maintain a precisely defined spacing. You will have to wait several days for the flooring to get the necessary strength - this should be taken into account in advance when planning the repair and finish.

An economical option for finishing is laying laminate. It can be fixed with your own hands without wet work. On the walls are often mounted panels of PVC or MDF. Alternatives - vinyl and quartz vinyl tiles, wallpaper. Sometimes goes and paint, all of these options allow you to imitate different types of natural wood.

What to wrap the outside?

Siding

This cladding material has proven itself perfectly in the finishing of baths and other auxiliary buildings. The vinyl material consists of two levels: the outer one protects from negative factors, and the inner one provides a reliable joint. Wooden siding is treated with additional additives. It looks quite attractive. But every year you will need to renew the treatment to protect yourself from insects that pose a greater threat.

Block Haus

The length of this material is from 2 to 6 m. Its strips (boards) are divided into 4 categories. Of course, the higher the category, the higher the price and aesthetic characteristics. The block-house is required to be mounted with waterproofing and crates. It is extremely important to ensure a firm fastening of the material and treat it after installation with antiseptic substances.

Imitation bar.

This option looks as if you actually put an old-fashioned log cabin. Regardless of the specific substrate material - brick or stone, aerated concrete or frame construction - imitation beams look attractive. The width of the product is from 15 cm. The design provides enhanced thermal insulation. Warning: if a substandard material is used, it often "leads".

Wooden linings

This type of exterior finish is quite common in the construction of baths. It is environmentally friendly and lasts a very long time. It is not difficult to install wood paneling. When using wood, antiseptic treatment is necessary. The base - a framework of thin wooden slats.

Plastic panels

This approach to the material:

- fast;

- cheap;

- easy to maintain;

- provides solid insulation;

- wear-resistant;

- does not require constant application of antiseptics.

Warm Plaster

It is praised for:

- optimal combination of warmth and soundproofing qualities;

- decent adhesion to almost any substrate;

- resistance to baking and rotting processes;

- mould resistance;

- No need to level the substrate thoroughly.

Finishing of the Russian bath differs significantly from the finishing of the sauna. Its authentic look is maintained by decorating a log cabin or its imitation. Paint and varnish is the easiest to apply. However, its resistance to meteorological influences is low. Log structures can be finished only after caulking.

The use of slab cladding is also becoming more popular year by year. To use it to cover the outside of the bath, initially requires disinvestment. It is better to entrust this task to professionals, because you will have to work with toxic substances. The bark will need to be removed by yourself. However, just this is not particularly difficult.

To conclude the review of options is quite appropriate for the cladding of baths profiled sheeting. High-quality corrugated board looks attractive and serves for years without losing its protective qualities. This material is even suitable for the formation of an increasingly popular now "ventilated facade. After installation, it looks at least as good as decent siding.

In areas with severe frosts it is better to use a sandwich panel, in which the sheet will be only a shell.

Useful tips

Not any wood can be used for upholstery on all surfaces, but only carefully dried wood, ideally in industrial chambers. Only bricks and tiles known to be non-combustible should be placed near the stove. Tile floor is cold, but this defect can be corrected by placing a removable wooden grate. Shelves are made of thick board with stud or nail fasteners. Do not nail or mount them with screws!

Additional recommendations:

- The tiled floor should be done before the work on the walls begins;

- it is better to insulate all surfaces from the inside with mineral wool;

- doors should preferably be made of glass;

- floor of pebbles looks unusual and actually massages the feet;

- It is necessary to choose a clear style, and even from his appearance to determine the materials.

Examples

- Sheathing bath outside siding, imitating the logs - a very solid and beautiful visually solution. The composition, especially in combination with the sharp part of the roof and the protruding terrace, is perceived quite well.

- The photo shows the combination of stone and natural wood in the interior of the sauna. The lighting is very original thanks to the lighting.

- And yet the walls are much more often covered with wood, but on the floor, as shown here, it is more correct to put tiles.

In the following video you will find the main mistakes when finishing the steam room in the bath.