All about the floors on spiral piles in the bath

The guarantee of longevity of any construction is a strong foundation. Hammered piles made of wood back in the ancient ages were used in the construction of baths, today they have been replaced by metal screw analogues - they have cone-shaped tips, as well as blades on the surface, it allows you to dive into the foundation more quickly and easily.

What are the requirements for the flooring in the bath, located on the screw piles, tell us in our review.

Features

To begin with, it is necessary to understand in what situations screw piles are needed, what are their positive and negative sides.

The pile foundation is used in special cases:

- When the soil at the construction site is permafrost or too heavily watered;

- when the building is built on the shore of a lake;

- in areas with frequent and severe flooding;

- When the future construction site has a sharp drop in elevation, or the bath is built on a slope, hillside or any other complex terrain.

The positive aspect of creating a screw pile foundation - It can be used on any type of soil, even very porous soils.

The most important thing is to choose the right material for the piles, then the features of the foundation, as well as the level of groundwater table will not be able to have any effect on the construction.

Advantages Screw piles are considered to be quick installation works and the possibility of their implementation with a minimum number of helpers or even independently. This does not require any special technical skills, because the pile foundation does not need the construction of formwork and other additional structures. In addition, you do not have to wait for the concrete solution to dry out, as in the case of strip foundation - you can start building the bathhouse immediately after installing the last flashing.

Other advantages include:

- achievement of maximum stability;

- ability to work under any natural conditions;

- screw piles provide natural ventilation in the bathhouse floor from the outside;

- convenience of engineering communications.

In addition, the screw foundation it is durable, practical and reliable.. With the competent installation of the floor, the walls of the structure will be reliably protected from the adverse effects of sediment and melt water.

However, there are also disadvantages.

- When installing the piles, it is very important that they have a level vertical position. When working alone it is very difficult to achieve this. In case of minimal deviation, the load-bearing capacity of the pile decreases by 15-20%, and this causes sagging of the building.

- There is no possibility to equip a full-fledged basement or cellar under the floor.

- Screw supports are made of steel, so they become a conductor of cold. When installing the floor is very important to make high-quality insulation of the structure.

- On the durability of the screwed pile foundation, the arrangement of the floor has a great influence. It should provide for both heat, and hydro, and vapor barrier layers, and its design should effectively remove water outside the building.

What are they?

For the arrangement of the floor in the baths on screw piles, most often use hardwood and softwoodThe floor material should be chosen carefully, although concrete screed has become very popular in recent years. Taking into account that any sauna is a room with special operating conditions, the selection of material for the floor should be approached as carefully as possible. So, the construction of concrete will be a reliable and practical base. However, its installation will be much more expensive than the arrangement of wooden flooring.

Boards made of softwood easily withstand the effects of moisture and temperature fluctuations, but they will have to be regularly covered with antiseptics, flame retardants and other protective compositions.

The service life of such a floor does not exceed 10 years, at the end of this period it will have to be replaced.

Despite this, wood flooring is considered more economicalSince at any time it can be repaired by simply replacing a damaged part without disassembling the entire structure. Timely treatment of the surface with fungicidal preparations increases the operational period of the flooring at least two to three times. In the bath it is possible to arrange a combined floor. For example, in rooms characterized by high humidity (in the steam room and shower room), it is better to make a concrete screed, and in all other rooms - a wooden floor.

How to do?

Preparing

Before proceeding to the installation of the floor, it is necessary to Treat all elements of the structure. Both piles and wooden workpieces are covered with antiseptic impregnations, flame retardants and other protective compositions. This helps to prevent the appearance of rot, mold and other pathogenic microflora. All further work can be carried out only after the boards and piles are completely dry.

Insulation

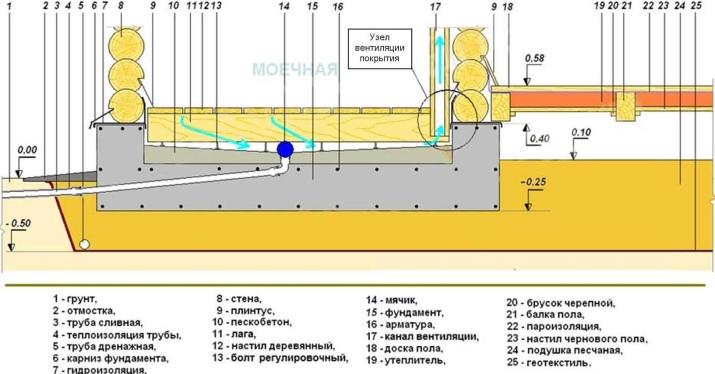

The best option for insulating the sauna room from below will be laying of thermal insulation. It is laid between the rough and finish structures, installed on the joists together with the waterproofing film.

Waterproofing must be paid special attention, as its quality largely determines the duration of operation of the structure.

In the bath on piles, several types of waterproofing are laid.

- In the case of concrete screed, it is resorted to melted roll-type waterproofing. You can also use a coating composition in the form of bituminous mastic.

- When installing wooden structures on top of insulation is usually laid waterproofing membrane or PE film.

Mounting the plinth

Insulate the floor at the screw pile foundation can be done by Insulating the basement along the entire perimeter. The main task of the basement is to isolate the space under the floor and not let the cold air masses into the room. In addition, it makes a much better look of the building.

Basement cladding is usually performed by means of thermal insulation boards, on which decorative panels are attached - they can imitate all kinds of natural materials (wood, stone, masonry). As a plate heat insulation is usually used foam plastic or foam plastic.

Once all the panels are fixed around the perimeter of the structure, the joints should be sealed with installation foam.

Arrangement

The most common construction for a bathhouse on piles is considered A spill/covered floor. However, it needs quality thermal insulation, especially when you intend to use the bath year-round. All the spent water in this case drains to the floor, and then leads to the drainage or sewage system through a drainage pipe, placed at a slight slope.

There are two main varieties of spill design. It can be completely wooden or combined. In the first version, the boards are fixed on top of the beams so as to provide between them a gap of 4-6 mm.

Under the flooring there should be a drainage layer - its role can be performed by crushed stone, laid on a sandy cushion. As for the height, it should not reach the bottom of the floor by about 10-15 cm.

During the operation of the bath, all the dirty water is taken out into the rubble, so there is no need to additionally install a sewage system.

However, this method has its disadvantages. In the wintertime, it will be cold in the room. In addition, the quality of water removal largely depends on the presence of sand in the ground.

More comfortable and practical is considered construction of the flooded floor, mounted above the concrete screed with a drainage hole installed in it. In this case, on the ground, laid at a slight angle to the drain hole, lay a layer of crushed stone, cover with a reinforcing mesh and perform screeding.

After that, the only thing left is to strengthen the beams and make the boardwalk.

Laying wood or pouring concrete

For year-round use of the sauna, you can also envisage Installation of a dry floor. For this purpose, pairs of boardwalks are made. One acts as a rough surface, on top of which a layer of insulation is necessarily laid, which is covered above and below with waterproofing material. The second (finishing) flooring is made of hard tongue and groove boards. Most often for its manufacture, coniferous wood is used.

When installing a concrete floor, first of all it is necessary to conduct sewer and water pipes, as well as to fix the drainage hole.

After this, the base is tamped and poured with a concrete mortar with a layer of 4-5 cm. Dried concrete is covered with a film, put insulation, waterproofed again and poured the second layer of screed, it should be reinforced with a metal mesh.

Finishing

To finish the floor in the bath on the screw piles is often used Tile or ceramic floor tiles. Usually under it put a second-rate board, plywood, chipboard and other materials that can be secured to the floor with a bar.

Under the tiles, you can additionally mount a floor heating system - for this purpose, an electric infrared or hydraulic system is used.

At the same time, the tile has its own disadvantages.

- under the influence of water, it becomes slippery, so when used in wet rooms, it is better to give preference to panels with a grooved surface.

- quickly heats up, and this makes it impossible and its use in the steam room.

Finally, the tiles does not match the style of traditional Russian baths, That is why most of the users prefer the wood paneling with a beautiful texture.

Preventive measures

The bath on screw piles is characterized by a high level of humidity, so it is very it is important to make the flooring as protected as possible from fungus and mold - they inevitably appear where water stagnates. To this end, even during the construction it is necessary to cover all elements of the construction with a double layer of special antiseptic compositions. In addition, the floor in the steam room must be treated with with fire retardants. In the finishing phase is applied water-repellent varnish or special wax.

In addition, the piles themselves every 5 years must be serviced. To do this, each of them is dug in at 40-50 cm and covered with corrosion-resistant composition. If you neglect such treatment, the service life of foundation will be significantly reduced.

As the installation of floors on screw piles, see below.