All about timber baths

The Russian bath has always been built of wood. Today it is not necessarily a log cabin, lately the bar is widely used, since this material has a number of significant advantages, which will be discussed in the article.

Pros and cons

Log cabins have an impressive lifespan. This option is something in between a frame and a log. It is easier to assemble and less time-consuming. At the same time, the building is reliable, durable and long-lasting.

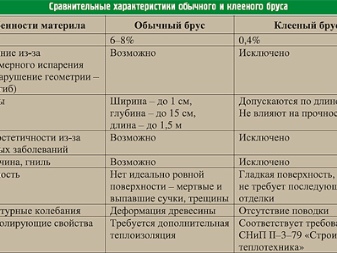

However, you should understand that Log house can be assembled from different types of timber, respectively, and the properties may differ. There are both advantages and disadvantages of log buildings, about which it is necessary to mention.

Conventional Bar.

In simple terms, a simple bar is a log with a square shape. Why exactly a square? It is much easier to lay, the tightness of the fit is higher, so a lot of caulking is not required. From the outside looks log sauna attractive, exterior decoration is required minimal, and you can even just treat wood with a stain or varnish.

Inside, the walls get even, so the user has the opportunity to save money on finishing the walls.

As for the disadvantages, there are quite a few, too:

- Over time, the structure sags a lot;

- If the wood is treated poorly, then over time there may be cracks in the material or it will deform;

- you will have to insulate the sauna, since even high-quality laying does not exclude the appearance of cracks;

- individual wreaths have a large area of contact, rot develops here;

- the length of a standard bar is 6 meters, in the organization of the bath of a larger size you have to connect individual elements, as a result of the formation of cold bridges.

Profiled bar

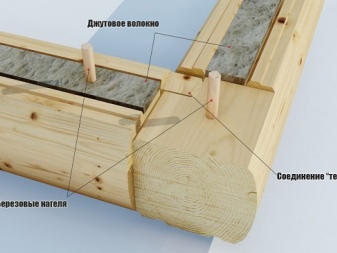

It is this in most cases is used to build baths. In simple terms - it is a solid, but a special shape, which gives it advantages when laying. There are grooves along the entire length of the beam.

The connection between the various elements of the bath is based on the principle of tongue and groove. Very similar to a construction set. The fit of the individual elements is very tight, hence the advantage of this type of building material over a log cabin.

If we talk about the advantages, it is not only durability and reliability, but also:

- low shrinkage;

- there is no need to use a large amount of insulation;

- inside for a long time keeps the heat, because there are almost no cold bridges.

However, it should be understood that such positive qualities of the bath will have only if the wood, from which the bar is made, is chosen correctly. The cost of the described building material is higher than even an ordinary bar. Without proper treatment can form mold.

A glued beam

From the profiled beam is not so easy to distinguish the glued beam externally, it's all about the manufacturing process. The described building material is obtained by gluing the individual lamellae, hence the name. Grooves in the design is not difficult to see, so the assembly of the bath with the use of laminated beams goes without much difficulty.

It is worth mentioning the advantages:

- there is practically no shrinkage;

- no wall deformation;

- thanks to the glue impregnation, the buildings have an impressive service life;

- rot, mold, and fungus are not afraid of laminated veneer lumber.

As for the disadvantages, and in this case, they could not be avoided. The quality of the building material largely depends on what processing technology was used. Once the manufacturer has decided to save money, then quickly become pronounced irregularities in the technological process. This is manifested by a simple delamination of the lamellae. As a result - the cracks in the beam itself. When the manufacturer is responsible for quality, the bath will last for many decades.

There is another significant disadvantage, because of which many people refuse glued beam - a chemical component. Despite the non-ecological nature of the material, it costs more than other options.

Comparison with a log bathhouse

Many even professional builders can not accurately answer the question, so what is better: a log or a log to use for the construction of the bath. There is nothing surprising, because both options have both pluses and minuses. If you compare the two options, it is worth taking into account several parameters.

Terms

A medium-sized structure with the observance of technology can be built in a period of 1.5 months. For a log bath takes the same amount of time, but provided that the building material is completely ready for use. The main difference is that with a log, you will be able to use the banya after an indefinite period, everything will depend on the humidity. When using a simple beam and profiled beam will need to wait for full shrinkage. This is not the case with logs. Such a sauna is ready for use no earlier than a year later.

Shrinkage

This point is very important in wood construction. With timber it can reach 10%. Glued material gives only 1-2%, so with it the bath can be used immediately after full assembly. Bar dried profiled shrinks by 5%, the one that comes with natural moisture to the previously mentioned 10%. Log house for the year will shrink by 12%, a minimum of 8%.

Labor intensity

The coveted bath can be built with your own hands, if you use a profiled beam. Included with the bath is a detailed drawing of where and how each element is installed. They, in turn, are all numbered. For the construction it is enough to take two more people and some mechanized improvised means. As for the log cabins, it is impossible to complete the task without professionals. Ignorance of some features leads to the fact that the structure turns out to be of poor quality.

Finishing

No less important issue - finishing. Depending on what kind of timber is used, finishing may or may not be necessary. If it's an unprofiled ordinary building material, you'll have to buy caulk as well. With logs, it's unambiguous, sanding and caulking are needed. Builders have a lot to say about this. Solid logs are more expensive, the construction process from it is time-consuming, but the result is a quality bath, durable.

For some people it is not price and time costs that play a role, it is durability that determines the factor. Regarding the foundation, the timber frame sauna weighs less, so it has a small load on the base. Accordingly, you can save money on the foundation. There is no definite answer as to what is better than a log or a log is able to retain heat.

As for additional treatment with antiseptic agents, it is necessary in both cases.

Designing

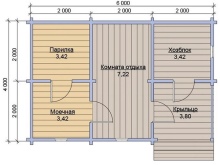

When drafting a bathhouse, you must immediately decide on the size, shape, and type of roof. A small one can be either rectangular or square. Recently, a small corner design has become increasingly popular. The construction of such a simple cheap bath is not a complicated process. Most often the foundation is mounted on piles.

Mini-baths are ideal for a cottage or a small family, elite ones are designed for a large number of guests and can reach the height of two floors. As for the roof, the most inexpensive variant will be a bath with a one-piece roof, but it is possible to provide a more complex version under the project.

Inside, the project provides for several rooms:

- steam room;

- rest room;

- shower room;

- changing room.

The steam room is designed based on the number of people. 200x200 cm is ideal. There are variants more or less.

When designing, you should take into account the possible number of guests, the necessary rooms, the number of floors. Since the bath takes additional space on the plot, it is tried not to make it too big. The most common options are 3*4 and 6*4 meters. This is enough to create a functional room.

It is advised to design a vestibule, as it will play the role of a dressing room, so you do not have to allocate space for this. Be sure to include a recreation room in the project. The recommended area is at least 6 square meters. The room should be comfortable and cozy, which is why it is desirable to provide a window in it. The bath must have a washing area. If it is not an area with a pool, but a simple shower room, then it is enough to allocate 3 square meters.

What kind of timber can be used?

By type of wood

Depending on the type of wood will differ and the properties of the finished building material.

Pine

For suburban construction, it is this wood that is most often used, since it is widely distributed throughout our country.

Of the advantages:

- ease of processing;

- baths from aspen beams do not lead, they do not deform;

- Pine has the necessary moisture resistance;

- low cost.

Of the disadvantages - too much resin content in the wood. As a result of increased temperature begins the process of release of resin. Moreover, if not additionally treated with such a bar with special agents, it will begin to rot.

Spruce

Spruce is used as often as pine, but it does not darken and for a long time retains its attractive shade. Since there is less resin in this species, it is more susceptible to fungal infestations. Moreover, spruces are too knotty, which could not but affect the quality of the building material.

Larch

Also a coniferous species. It is valued for its durability, hardness, small percentage of shrinkage, resistance to fungus and mold. Larch contains phytoncides, so the buildings made of it have beneficial effects on human health. Of the significant drawbacks: high cost and resin content, which sometimes has a bad effect on the health of allergic people. Otherwise, a bathhouse made of this wood is always a worthy choice.

Cedar

Cedar lumber is a luxury that not everyone can afford. This is because the harvesting of such a forest is limited. The uniqueness of cedar as a building material lies in its fibrous structure. As a result, the walls are minimally susceptible to deformation.

It is worth mentioning other advantages of cedar beams. It has a high resistance to rotting. Withstands rising temperatures and high levels of humidity. It is impossible not to mention the aesthetic component. The color of the wood is very attractive. Additional health effects due to essential oils, as one of the positive qualities. The disadvantage of such a timber is only one - the price.

Lime

For the construction of the bath, this species is not often used. Despite the fact that it is easy to process and there is absolutely no oil in it, it does not cope with a lot of moisture. Aroma and low heat capacity, due to which the room heats up twice as fast, do not cover such a negative quality, as short-lived. It darkens quickly, in addition, it is susceptible to mold and rotting.

Use lime can be used to finish the sweat room, but the structure is not long-lived, although it does not give much shrinkage.

Aspen

Aspen timber is similar in characteristics to linden, but it does not crack when dried, it is more moisture-resistant. It also shows minimal shrinkage and has a bright ginger tint.

Of the disadvantages:

- It is difficult to handle;

- it is not always possible to keep track of quality.

In our country, aspen grows rotten inside, so most of the wood is imported, hence the cost.

Oak

The uniqueness of this wood lies in its hardness and strength. This kind of timber has excellent resistance to elevated temperatures and has a unique color as well as a distinctive texture. Despite all this, for the bath such a building material should not be used. The reason is simple - the wood is afraid of moisture and cracks during subsequent drying.

Moreover, weighs a lot of oak, so under such a sauna will need to organize a solid foundation, and this is an additional cost. Difficult to handle a beam made of oak, and the cost of the material is quite high.

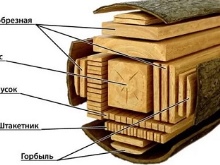

According to the method of production

All types of beams can be classified as follows.

- Profile.

- Calibrated.

- Calibrated.

- Planed.

- Double.

- Chamber dried.

- Half-timber.

Profile bar is so called because of the special grooves in its design. Cylindrical log is the same round log, only mechanically processed by a special machine. It can be dried and natural humidity, the level of which should not exceed 22%. Under the calibrated log means any kind, but with a set size. Accordingly, the entire batch must have the same cross-section.

Sliced beam refers to dry lumber, which is pre-processed on the machine and grinded. Hence it has an ideal shape. Wooden bath from such material - one of the best solutions. Chamber-dried material is a well and evenly dried timber, which went through a stage of cleaning and profiling. Under the double refers to a special construction, which includes two boards and necessarily conifers. They are arranged in parallel to each other.

The half-timber is perfect for the sauna. It is a material that is half the diameter of an ordinary beam.

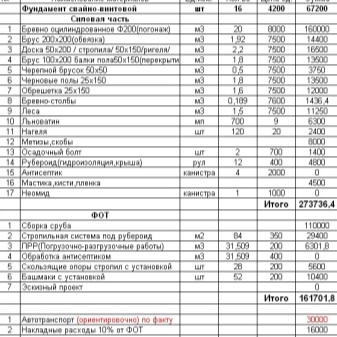

Construction stages

In any construction, preparatory work plays an important role. First, the place where the bath will be erected is chosen. According to existing standards and requirements, a wooden structure can not be close to the house, to harm the laid communications. The SNiP clearly prescribes the distance from the nearest buildings. In the case of the bathhouse it is not less than 3 meters from the living space, 4 meters from the trees and 5 meters from the bushes. From barns with animals the bath must stand at a distance of 4 meters.

When all the markings are set, it is time to create a project. The drawing outlines a sketch of the building and the internal layout. A detailed estimate is made for the purchase of materials. Now you need to coordinate the bathhouse with the administration, because one complaint from the neighbors - and it will simply be demolished. The project necessarily requires approval. In order to obtain a positive decision, you will need to submit to the supervisory authority:

- a floor plan;

- an estimate;

- a description of the foundation.

Among other things, the consent of the neighbors will also be required. Any construction begins with the foundation - and the bathhouse is no exception. When choosing its variety, you need to take into account the topography and type of soil. Given the low weight of the log cabins, you can use a strip version. When the terrain has large drops, and this is more than 1 meter, it is worth choosing bored piles as a foundation.

When the foundation is ready, you can buy the timber. If the construction is planned in an area with a temperate climate, then it is very important that the thickness of the building material was at least 200 mm, and otherwise the heat inside will not be retained for long.

If you save on the section of the log, you can overpay later, because the cost of insulation will exceed the purchase of quality timber.

It is very important to pay attention to the following points:

- The log should be without defects, namely - cracks and chips;

- Be sure to pay attention to the thickness, all logs should have the same indicator, the difference may not be more than 3 cm.

The next stage of construction work - laying according to the scheme of the building material. You can do the work yourself or call for help from a team of specialists. In principle, there is nothing difficult, because each element of the already prepared for the bath constructor is numbered, and a detailed laying scheme is attached to the kit. As the last step - laying the roof and finishing inside and outside, if necessary. Sometimes the selected timber looks attractive even without finish, so no additional expense may be necessary.

Beautiful design examples

Modern design offers many options for what a log cabin can look like. You can make an original project on your own or involve a professional.

- A small bathhouse as a vivid example of how the room 3*4 can decorate the country site and give joy to a small family.

- A medium-sized bathhouse with a loft space that can be used as you see fit. A small veranda can become a place of comfortable rest for the owners and guests.

- Not bad, but an expensive variant of glued timber. The dark color of the wood goes well with the design of the door and windows.

Review of reviews

Among the reviews of owners there are many positive, but there are also negative ones. Residents of northern regions say that the thicker the log, the longer the heat stays in the bath. At the same time, it is necessary to pay attention to the quality of the purchased timber.

Not often, but we have to deal with unscrupulous manufacturers who use bad wood in the creation of the building material. Numerous users advise not to trust the seller and to check the moisture level yourself. If this point is overlooked, a large percentage of shrinkage and the appearance of cracks in the walls is likely.