All about the log baths

Log cabins are quickly erected constructions and are in active demand on the domestic market. Experienced teams erect buildings in days. Speed of installation, environmentally friendly material and beautiful appearance incline customers to give preference to this type of baths.

Features of

More and more owners of country houses, turning to the old Russian traditions, install bathhouses on their plots. Often as a material for the construction of customers give preference to the log. Нespite many modern building products, wood is still popular. It is difficult to compete with its characteristics and performance properties.

Wood is easy to handle, so you can build a bath by your own efforts, with minimal experience in construction and knowledge of the principles of fixing logs.

Constructing a structure, you should take into account some of its features:

- The logs must be treated with special bactericidal impregnation;

- The wood gives cracks that need to be sealed, if this is not done, the walls will be blown out;

- A bathhouse built from damp logs will require a long shrinkage period, and only then you can install windows and doors, and do the finishing work;

- Laying of the furnace and the organization of the ventilation system is better to trust a professional, the safety of the owners depends on this.

Advantages and disadvantages

Wood is not only beautiful, it is pleasant to the touch and carries a special magical energy of the forest. It is comfortable and safe to be in such a bathhouse. It has many advantages.

- Low thermal conductivity allows it to retain heat in the room for a long time, creates a pleasant microclimate.

- Wood is able to pass steam, preventing the accumulation of condensation. It provides good air circulation.

- Log walls are excellent at insulating noises.

- Wood is malleable and easy to work with. You can quickly build a log cabin from it, and also decorate it with carvings.

- If the logs are properly treated with antifungal agents and coated with a protective layer, the sauna will be able to last for several generations. The main thing is to make sure that the foundation rises above the surface of the ground and does not allow the wood to come into contact with it.

- Sauna from a log will cost less than a brick building, but will be more expensive than block options.

- For people who are tired of glass and concrete, log cabins seem fabulously beautiful.

Unfortunately, the wood has its disadvantages. About them it is necessary to learn in advance, even before the construction of the bath.

- Wood is a fire hazardous material, even a special treatment does not give a full guarantee.

- A log cabin made of fresh material is subject to long shrinkage time. The choice of well-dried logs can help reduce this period.

- Over-dried timber is prone to cracking.

- In damp climates, poorly treated walls can be affected by fungus and mold.

To avoid a lot of trouble, you should choose the right type of wood and a good team of carpenters to build a bathhouse.

Dimensions

The size of the bath depends on the wishes of the customer, and the wishes are dictated by different conditions. The following criteria are taken into account.

- For how many people to visit it should be planned.

- How often the bath will be needed by the owners. If it is located near a house, you can count on frequent visits, and, accordingly, a large area. If the bathhouse is built in the country and is needed from time to time, then there is no point in investing in a large bathing complex.

- A sauna for receiving guests needs a large size, it may need a pool and a relaxation room.

- If the area on the site is small for a log cabin, respectively, and its dimensions will be small.

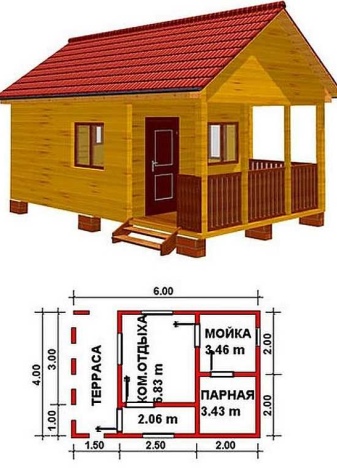

Brigades engaged in building baths, can offer their worked-out size. Projects of minimal buildings contain parameters - 3x4 m, or 3.5x3.5 m. Typical projects of classical log cabins are 4x6 m or 6x6 m in size. Can also offer averaged options - 5x4 m and 5x6 m.

Materials

To erect a log cabin, you will need not only logs, but also painting materials, sealants, cement base for the foundation, roofing and more. On the quality of materials largely depends on the reliability and durability of the structure itself. Of course, the lion's share falls on wood. In most cases, the use of pine solid wood is practiced, it is inexpensive. But pine is not a dense species of trees, such as oak, hornbeam, cherry, acacia and larch. If the wood is not properly treated, it will swell from the rains, begin to rot, can be covered with fungus or mold.

For the construction of the bathhouse carpenters use raw, dry or semi-dry logs. The shrinkage time of the finished structure depends on the degree of dryness. The more the log is dried, the less time it will take before the beginning of interior work. In this case, you should pay attention to the material from the winter felling, it is in this period of the year the wood contains a minimum of moisture.

Before you start construction, harvested material should be inspected for defects. Logs with cracks, chips and other defects will look unaesthetic and will require additional sealing. The classic thickness of the log is 21-25 cm, if you choose thinner options, the walls will be worse to retain heat.

Beautifully look baths from large billets.

The finished material is treated with fire retardant and antifungal impregnation. Paint or varnish can be used as a protective layer. But in most cases, customers prefer to preserve the natural beauty of the wood.

Foundation

For the construction of a bathhouse, especially a large size, a strip foundation is used. Along the perimeter of the future building a trench is dug, then the following materials are used.

- Pebbles, small stones. Backfill the site for construction, this material will perform drainage properties.

- Boards. Of them build a formwork along the entire length of the trench.

- Iron armature. It is laid inside the formwork for the adhesion of concrete.

- Cement. ЗPoured in the formwork.

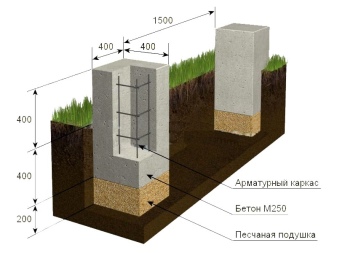

On shaky sandy or boggy soils, soils with strong moistening or freezing and on uneven ground, pile foundations can be used. The cost of its work is lower than that of the strip version. For this type of construction, the following materials will be needed.

- Concrete. It is used to make a concrete pad, on which the pipe is later installed. Concrete will also be needed for pouring the pipe itself.

- Sand. Necessary to create a concrete cushion, it is the first layer, covers the ground.

- Tube formwork. It is from the hollow pipes, poured concrete, is built a columnar foundation for the bathhouse.

- Reinforcement. It is laid inside the pipe and helps to hold the cement mortar.

The foundation, which is prepared for the construction of a log cabin, derive 20 cm (you can more) above the surface of the soil, so that the wood is not in contact with the soil and does not rot.

Walls

Along the foundation, a brick plinth with ventilation holes is installed. The next material that will be needed after the cement dries will be roofing felt. It covers the foundation, on it lay a circle of boards, treated with mastic, it will keep the walls from rotting in the future. And only after all the preliminary work begins laying logs. They come in different types.

- Hammered. During processing, the logs leave only the core part, it is quite strong and less prone to shrinkage. Products are perfectly smooth, round, the same size. They are treated with protective compositions at the production stage. Log cabins are built quickly and do not need interior finishing.

- Sliced. Produced by removing a small layer of the upper part of the log with an electric planer. It turns out smooth frost-resistant workpiece.

The disadvantage is the mismatch in diameter between the two ends of the product.

- Log carving ("Norwegian chopping"). Processing of wood material is made on both sides, so the billet becomes flattened appearance and somewhat resembles a large beam. The bath from such material gives less shrinkage and cracks.

- Chopped. The log is processed by scraping by hand, and all its natural properties and structural pattern are preserved. The disadvantages include a labor-intensive process and long shrinkage.

- Calibrated. The material is selected according to the specified project length and thickness. Often such logs are made from prefabricated rounded billets.

Floor

A bathhouse is a specific building with high humidity and high temperatures. Not every material is suitable for the floor. In addition to technical, it must also withstand the sanitary standards. The following types of materials are used for the floor of a log bath.

- Well-treated boards, which are laid out in a solid flooring. Or do strip flooring, leaving even gaps for the outflow of water.

- Concrete screed has the advantage, it can last up to 50 years, while the wooden floor - up to 10 years.

- Tile floor does not rot, does not absorb water, does not burn, it is easy to care for. You should choose tiles with a rough or grooved surface to avoid slipping on a wet floor.

Roof

If the sauna is small, it will be suitable for a single-slope roof, for a large structure, you can choose a gable version. As the material for the roof you will need wooden beams and boards for the crates. The coating itself can be made of ondulin, slate or different types of tiles: metal, flexible, ceramic.

Finishing

Finished log bathhouse looks great outside and inside, especially from the cylindrical material. But it still requires some finishing work. Proceed to the finishing work can be done after the end of the shrinkage of the log cabin, otherwise the finish will give cracks or will crumble.

External

After caulking, sealing the walls should be removed all visible manifestations of this process. External finishing is better to conduct a minimum, to preserve the beauty of natural wood. It can be protected with antiseptics, stain or varnish products that will not hide the texture and even emphasize the pattern.

But some customers change the design of the building and decorate it with siding or brick, laying an additional layer of insulation.

Interior

Internal walls of a bathhouse made of logs can simply be varnished, preserving their natural appearance. If the walls are airy, we suggest to cover them with board or batten, and to put insulation between the outer wall and the cladding.

Project variants

Log cabins are so diverse that you can get lost choosing the right project. We will help to understand this topic. Before proceeding to the design, find a place for the bath on the plot. Remember that according to fire safety rules it must be separated from any building by 8 meters. It may be necessary to leave some space for a carport.

Then decide on the size of the building, the number of rooms desired and the budget. Then proceed to the creation of an individual construction plan. It can be obtained in several ways:

- to borrow from the Internet;

- develop their own;

- entrust a specialist.

A traditional bathhouse should contain a steam room, a washing room, a pre-bath, a changing room. This list can be reduced due to lack of space and budget or expanded, adding comfort to the bath.

Compact baths

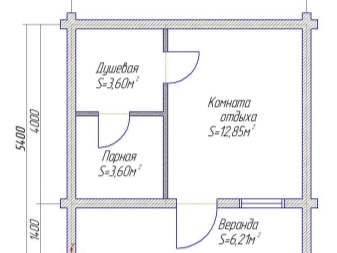

If there is no space for a sauna with a traditional set of premises, besides, the budget is limited, choose a project with a minimum number of rooms, more specifically - with two:

- Bath and washing room are in a common room;

- The anteroom, the locker room occupy the second room, in the same is the entrance door.

The project is inconvenient because for the shower is not necessary for such a high temperature, which sustained in the steam room. Solve the problem in different ways: a corner with the washing room is placed a little below the level of the bath or placed near the front door for forced ventilation.

Large buildings

Who has unlimited space and budget for construction, can realize any of his fantasies. To the traditional list of rooms are added a room for rest, furnace room, massage room. Sometimes bathhouses are combined with guest houses, where on the first floor, in addition to the bathing complex, have a kitchen, dining room, bathroom, and on the second floor - bedrooms, billiard room, and so on. Large bathhouses may have a swimming pool.

Verandas, gazebos and terraces with a barbecue area are attached to them.

Sauna-house

Sauna connected to the house can be built in two ways.

- In the project of a log cabin with living rooms immediately contains a place for the sauna. A large log structure is created on a single foundation and under one roof.

- Attached to the finished house is a log sauna. The two buildings have different foundations and different roofs, and a shrinkage joint is provided between them.

This option is considered unsafe. The bathhouse contains an open fire stove and increases the risk of fire of the residential building. The pluses of the combined project include increased comfort. The construction is especially convenient for families with elderly people and young children.

There are other options for projects.

Classic

Refers to typical constructions, most often offered by construction firms. One-story classic baths contain the traditional set of rooms - steam room, washing room, anteroom with a dressing room and a place to rest. As an example here is a project of a log cabin with the parameters of 6x6 m, which is endowed with all the necessary rooms for a comfortable stay in the sauna.

With a veranda

Veranda, attached to the building, there are open and closed type. If the sauna is used in winter, the veranda not only needs to be glazed, but also insulated. If you take care of air tightness and heating, this room can take on the function of the resting place.

Baths with verandas can be of two types.

- Built together with the main building and having the same foundation and roof.

- Attached to the old log house or immediately after the completion of construction. In such cases, the veranda has its own roof and a separate foundation, most often pole.

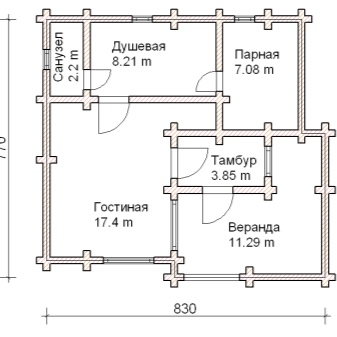

As an example, consider the project of a one-story bath (60 square meters). Veranda has an exit to the vestibule, from which you can get into the recreation room. The steam room is located in the far corner from the entrance and is endowed with a single passageway leading to the shower room. Thanks to a reasonable layout, the heat in it is well kept.

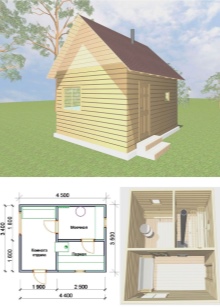

With a loft

An attic helps if you want to build a sauna on a small piece of land, for example, 3x3 m or 3x4 m. Steam room and vestibule located on the first floor and the rest room on the second floor. Interstage separation helps to maintain the necessary microclimate for each individual room. In the summer bath the stairs to the attic can be external, and in winter it is convenient to build out of the vestibule.

The attic is also used to build a guest house with a sauna. The first floor is allocated directly for the bath and the accompanying rooms, and on the second floor there is a bedroom and a guest room.

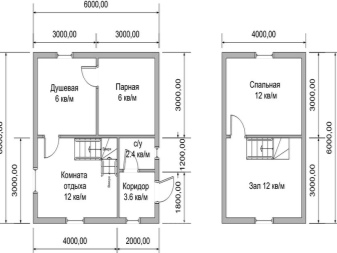

As an example, consider the design of the bath-house with dimensions of 6x6 square meters.

With a recreation room

If the size of the bath is not reduced to the minimum two rooms, the rest room can be organized anywhere, especially in the summer version. A place where you can relax, drink a cup of tea, talk to family or friends, is not so demanding to the technical characteristics. It does not need to be protected from water and hot steam. So, the rest room can be located in the following places:

- directly in the log cabin itself, next door to the vestibule or washing room;

- In the attic;

- on the veranda;

- terrace;

- in the gazebo;

- on a large porch under a canopy;

- on a wooden planking or a concreted area by the bathhouse, where the summer furniture is taken out for relaxation.

Most of these places can be combined with a kitchen or barbecue area, combining bathing procedures with sitting with barbecue. We propose to consider a project that contains several places for recreation at once:

- In the winter version, the guest room is located in the log cabin and has two exits: to the shower room and on the veranda;

- In summertime you can relax on the veranda itself.

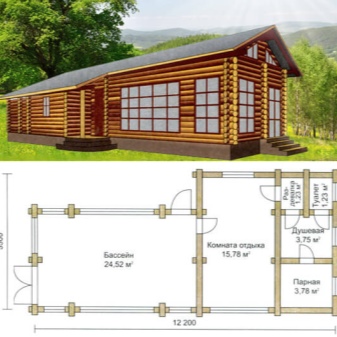

With a pool

Swimming pools have a certain specificity, they are usually not completed, and are included in the project of the bath even before the start of construction. In the room with a swimming pool leads to a water supply system, preparing a thorough drain on the type of sewage. Wiring, walls and ceiling are subjected to careful waterproofing. Small bathing can take place directly in the steam room for a large-scale pool built a separate room. During construction, the location of the ventilation system, water filters and lighting are taken into account.

We propose to consider the project of the bathhouse with a swimming pool, size 10x8 square meters. The pool is about 8 square meters, located in the corner bay window part of the building, has access to the shower room. The bathhouse contains a large veranda (over 15 square meters), located at the two adjacent walls, which rests against the room with the pool.

Beautiful examples

Any wooden log cabin, even without decoration, turns out to be exclusive and arouses enthusiastic feelings in many people. It brings closer to nature, brings peace and tranquility, something that is missing in our fast-paced modern life. Appreciate how splendid such simple buildings as baths turn out.

- Elite log cabins made of large logs are ornamented with perfectly finished end slices.

- The unusual design of the sauna looks like a house from a fairy tale.

- Construction of log sauna with a terrace and barbecue area.

- Bathhouse with a canopy, decorated with artistic wood carvings.

- Chalet-style guest house with a bathhouse and a terrace equipped as a recreation room.

- The log cabin is unique with its roof, which has a living lawn.

Whoever decided to install a sauna, can safely choose a log as a building material. Such a building will give a sense of the pristine beauty of nature, fill you with energy and health.

See the following video for a review of the 8x10 bath from the logs.