We choose heat insulation for baths and saunas

The amount of heat loss of the working bath directly depends on the quality and properties of the thermal insulation material used in the process of its internal finishing. Modern market of finishing materials is replete with numerous names and types of heat insulation, which have very different performance characteristics. Let's take a closer look at the properties that should have a good insulator for the bath, what kinds of them are found in the modern sale. Choosing heat insulation for baths and saunas

Features

Insulating materials are used to reduce the amount of heat loss of the structure, increasing its thermal resistance. Their use in the internal and external finishing of baths and saunas is aimed at solving such key tasks as:

- minimizing the loss of heat accumulated inside the building;

- Prevention of freezing of the building during the cold season.

Using insulation in the finishing of the bath or sauna assumes its further use in conditions of high temperatures and humidity.

Considering these and other features of operation, it is necessary to allocate such important characteristics of quality insulation for the bath, such as:

- moisture resistance;

- environmental, chemical and radiation inertness;

- resistance to strong temperature fluctuations (average range -30 ° C to +100 ° C);

- fire resistance;

- durability.

The insulation must be resistant not only to the development of fungus (mold), but also to the defeat of insect pests. In addition, it should not attract rodents (mice, rats), which often make nests in the thickness of the insulation, damaging and destroying it.

Overview of types

Modern manufacturers offer an impressive list of insulation for baths and saunas, varying both in price and performance characteristics. It should be noted that Products of many domestic manufacturers on the quality and range of properties is almost no different from expensive imported counterparts. Below are the most popular types of heat insulation used in the interior decoration of modern saunas and baths.

Foam plastic

Styrofoam is one of the most well-known polymeric materials with excellent thermal insulation properties. This insulation is popular because of its low cost, lightness, density. It can be easily processed, easily assembled into blocks of any size and shape. Foam boards can be attached to the wall of the bath or sauna with self-tapping screws or bolts. To the disadvantages of foam plastic include its vulnerability to high temperatures. Under their influence, it not only deforms, but also releases into the air toxic and carcinogenic substances - phenol and formaldehyde.

For this reason, experts recommend using this material to insulate the pre-bath (preferably on the outside).

Penotherm

Penotherm - another popular polymer insulation, used in the finishing of baths and saunas. The basis of this material is foamed polystyrene with additives in the form of plasticizers and flame retardants. This insulation is characterized by low weight, plasticity, ease of processing and laying. It is not subject to rotting, exposure to strong temperature fluctuations.

For insulation of baths and saunas is usually used a kind of foam-therm with the label "LF"meaning additional protection of the material in the form of aluminum foil. Reflective foil surface greatly enhances the thermal insulation properties of the base material, helping to preserve heat in the bath. To the disadvantages of foam thermal experts refer to its high cost.

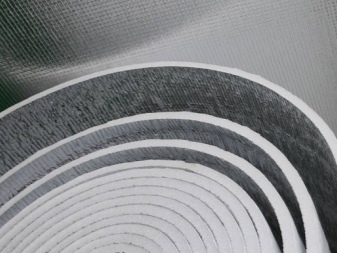

Isolon

Isolon - another type of inexpensive insulation based on expanded polystyrene. Its distinctive features are its light weight, flexibility and plasticity, high thermal and sound insulation properties. It is not exposed to moisture, UV light, corrosion and chemicals. Manufacturers of this material claim that a layer of Isolon thickness of 1 centimeter is able to equate the thermal insulating properties of 15-centimeter brickwork. With all these advantages to the disadvantages of insulation include its solid cost.

Basalt

Basalt insulation is considered by experts to be the best thermal insulator for the walls of baths and saunas. This moisture-resistant material is resistant to both high and low temperatures. It is fireproof, durable, environmentally friendly. Under the influence of high temperatures, basalt heater does not release hazardous substances into the air, does not deform and does not collapse. Another important advantage is that it does not attract the attention of insects and rodents.

In addition, basalt insulation is easy to install and provides not only excellent heat, but also sound insulation. By its disadvantages, experts include the large weight and high cost.

Interwoven

The inter-woven insulation is used to minimize heat loss in log cabins. In the old days, moss and flax were used as insulation between wreaths. Modern craftsmen use roll jute insulation, which has a high density and uniform structure. The laying of this malleable and environmentally friendly insulation is quite simple and does not require the use of special equipment. The disadvantages of jute insulation include its susceptibility to brittleness, which reduces the thermal insulating properties.

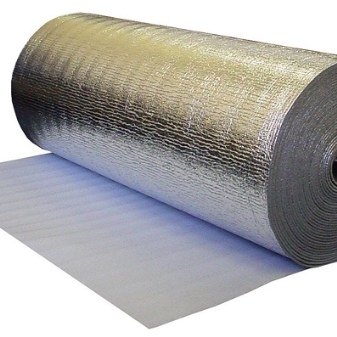

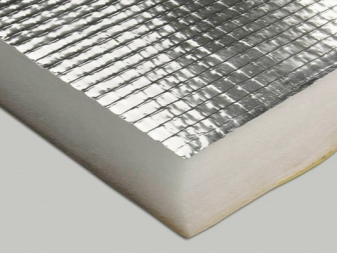

Foil

Foil roll insulation is usually used for finishing the ceiling in the steam room and washing room. It is lightweight, flexible, hygienic, flame retardant, easy to handle, does not emit toxic substances when exposed to high temperatures. Reflective aluminum surface of foil material allows not only to keep heat in the bath, but also to improve its internal illumination. The disadvantages of this type of insulation include its susceptibility to rapid wear and corrosion.

To extend the life of the foil insulation, experts recommend wiping its surface dry every time after bathing procedures, as well as periodically treat it with a special protective agent.

Claydite

Claydite - a practical, non-combustible and inexpensive type of insulation, which is often used for thermal insulation of floors and roofs. This loose, lightweight and environmentally friendly material is not affected by moisture and high temperatures. It is resistant to rot and chemical attack. In addition, experts refer to its merits unsurpassed durability. One of the important nuances of working with expanded clay is accuracy. When keramsite granules are damaged, their thermal insulating properties are significantly reduced.

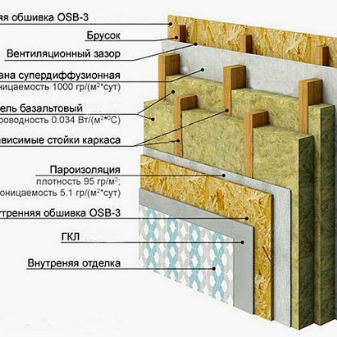

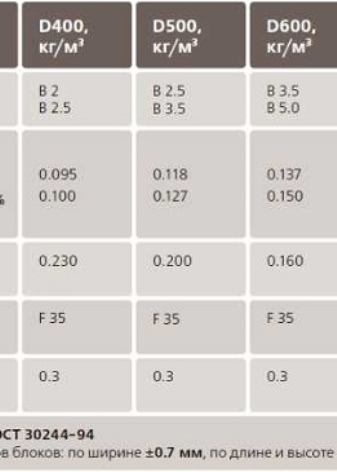

Mineral wool

Mineral wool is another common and versatile heat insulator, which is very popular in the field of construction and arrangement of engineering communications. This type of insulation is resistant to high and low temperatures, chemicals and detergents components. It does not attract insect pests, is characterized by fire resistance, low weight, ease of installation.

With competent installation mineral wool slabs provide good heat and sound insulation of the building. The disadvantages of using mineral wool as insulation experts refer to the need to combine it with vapor- and waterproofing materials.

In addition, this type of insulator is also characterized by a high cost.

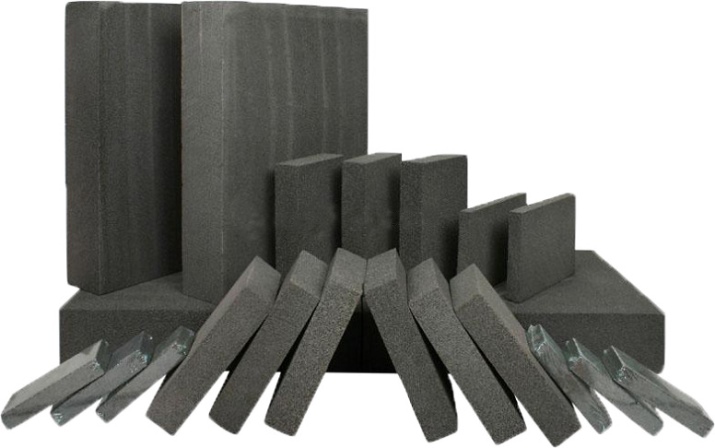

Cellular glass

Cellular glass is a modern, environmentally friendly material, used for the insulation of residential and non-residential buildings. Representing blocks with a porous structure, this type of insulation is characterized by low weight. Other advantages of this material include moisture resistance, strength, durability, density, resistance to high and low temperatures, as well as aggressive chemicals. This insulation does not attract the attention of insect pests and rodents. It is relatively easy to install, providing not only reliable thermal protection, but also good sound insulation. The significant disadvantage of cellular glass is its impressive cost.

Which one to choose?

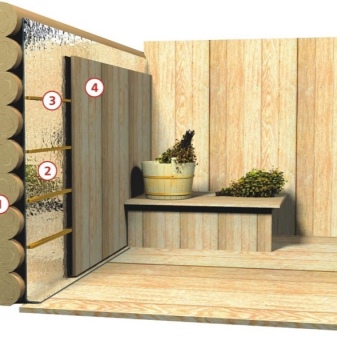

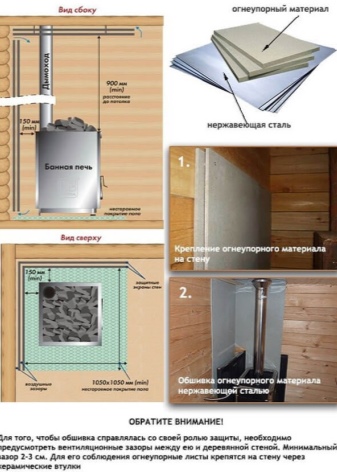

When choosing a thermal insulation for the bath, you should consider the features of the construction for which it is purchased. Thus, The best option of a thermal insulator for the floor, experts consider expanded clay, for the walls - basalt insulation and mineral wool, for the ceiling and chimney - foil materials. The roof of the structure can be insulated with expanded clay or blocks of mineral wool, protecting the latter with vapor and waterproofing. For insulation of unheated pre-bath it is easier and more profitable to use the panels of ordinary foam. You can use them both inside and outside the pre-bathroom by placing the blocks into the previously made boarding. The most expensive material for thermal insulation is cellular glass. To reduce the cost of construction and finishing of the bath, it is recommended to use it in the arrangement of the steam room, the construction of which is considered the most expensive.

To insulate the walls of a log bath, experts recommend buying a strip jute. It is important to note that the insulation with the help of this material should be implemented directly at the stage of construction of the walls. Later, after the shrinkage of the log cabins, seams and joints, insulated with jute fiber, will acquire tightness, vapor and moisture tightness. Due to this, the degree of thermal protection of the building and its resistance to low temperatures from the outside will increase many times. To insulate a brick bath, it is desirable to purchase natural insulating materials that do not emit hazardous substances into the air when heated. Previously inside the premises to be insulated, arrange a wooden frame (crate) for laying blocks of insulation material.

Choosing the right insulation materials for the bath or sauna, it is worth considering and their performance and manufacturer's recommendations. Thus, it is not allowed to purchase and use flammable materials for the arrangement of the steam room, as well as rooms in which the furnace part of the furnace. In addition, for the finishing of these premises is not recommended to use insulation materials that release toxic substances into the air under the influence of high temperatures.

When choosing and buying insulation, you should pay attention to its marking. So, marked "G" denotes materials that are prone to fire. For weak and moderately flammable insulation includes materials marked "G1" and "G2". Marking "G3" and "G4" denote normally and highly flammable materials. If the packaging of insulation is marked NG, it means that the material is flame retardant or not subject to combustion.

This marking, in particular, have this type of insulation materials such as basalt, expanded clay, rock wool.

Ecological soundness of the insulating material is another important criterion that should be considered when choosing a thermal insulator. The safest for the environment and human are materials on a plant basis - for example, insulation made of hemp, linen or jute fiber. The least environmentally friendly are thermal insulators based on polyurethane foam.

Another parameter that you need to pay attention to when choosing insulation for the bath is the weight of the material. Experts recommend using insulators with low weight in those parts of the building where they will not be under pressure. Otherwise, lightweight insulation will shrink over time, lose its shape and lose its thermal insulation properties. It is not recommended to place heavy insulation (e.g. expanded clay) on sloping or uneven surfaces. Disregarding this rule can lead to the fact that over time the insulation will be shifted to the side and will damage the surrounding structures.

On how to intelligently choose insulation for baths and saunas, see the following video.