All about the insulation of the steam room in the bath

Modern bath, which is finished with environmentally friendly and beautiful materials, it is impossible to imagine without high-quality material for insulation. This process is quite responsible and complex, because it will be necessary to choose the right materials and clearly follow the basic rules of performing such work.

Features

Thermal insulation of the steam room must be carried out taking into account many nuances. Only in this case, you can be sure that the work carried out will not harm the bath and will help to make it comfortable for use in the winter.

Most people think that the easiest way to insulate a bath is to insulate it from the outside. Moreover, it is much easier and safer to lay insulation in this way, but it is only suitable for brick buildings. If the bath is wooden, then it will be necessary to insulate from the inside. Among the main advantages of such work are the following:

- Providing protection for the walls from the influence of high temperatures and vapors;

- insulation is located throughout the inner part of the wall;

- The box of the steam room, which is responsible for internal ventilation, is not covered.

In addition, qualitatively carried out insulation allows you to guarantee rapid heating of the room, as well as optimal fuel consumption.

As a result, the most optimal microclimate is created in the bath, which greatly increases the effectiveness of health-improving procedures.

Choosing the materials

It is worth paying close attention to the materials used, because the result of all the work depends on it. The modern market offers a variety of materials that differ not only in price, but also in their functionality. Huge popularity is enjoyed by insulation materials made of aerated concrete, logs or blocks. In the Russian and frame bath can be insulated with penoplex. You can highlight the most popular and optimal materials for the insulation of the bath.

- Basalt wool, which is offered in rolls. A distinctive feature of such material is its resistance to fire, as well as the absence of any hygroscopicity. It can be used not only for thermal insulation of floors, but also for the chimney.

In this case, basalt wool can not be used to insulate the floors.

- expanded clay - Balls with a completely smooth surface. Can be used as backfill for insulation of floors and floors. The main advantage is that the material does not burn and does not absorb moisture.

That is why it is great for insulation of cavities and other hard-to-reach places.

- Foam - Foamed polystyrene sheets, have a thickness of 1-15 cm, which makes them an excellent insulation material.

The main drawback is that the foam is flammable and during the smoldering can release toxic substances for humans.

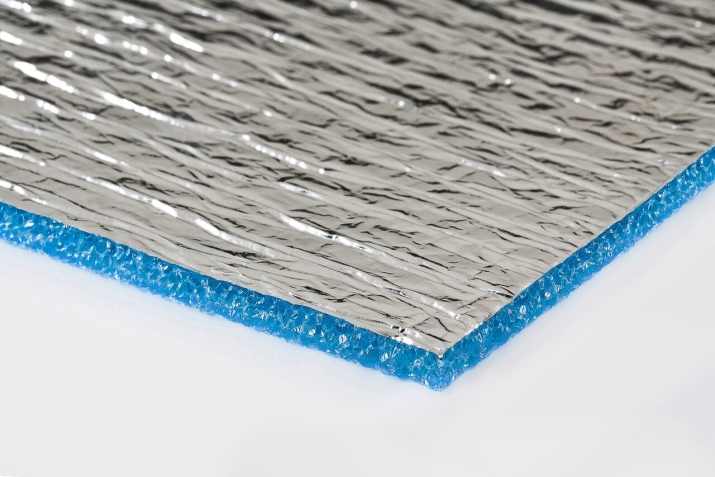

- FoamFoil - is a polyethylene foam, which is usually used as additional insulation.

A distinctive feature of foamed plastic is the ease of installation, as well as the ability to retain its shape even at high temperatures.

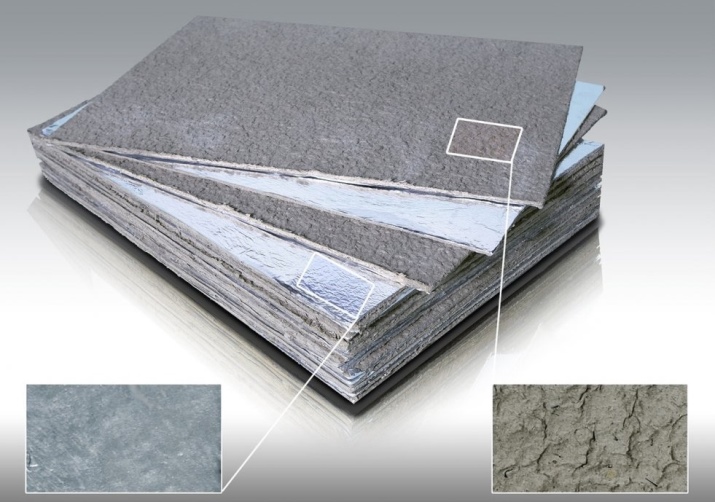

- Foil board - is used very rarely. It is a thick cardboard, which is additionally treated to give it the properties of protection against moisture and fire.

It is actively used when it is necessary to organize a quality vapor barrier.

During the choice of material must be very careful, because it depends on the ability to retain heat in the steam room. In addition, it has a direct impact on the amount of fuel used. It is worth highlighting the main points on which you need to pay attention during the choice of material.

- Thermal conductivity. Walls and floors should be insulated with special materials, the coefficient of which is not less than 0.08 W.

- Ability to resist the effects of moisture. In the steam room is always extremely humid, so the material under the influence of moisture should not lose its properties.

- Durability. Any selected insulation must cope with high loads and do not lose their integrity.

- The ability to withstand temperature fluctuations. It is worth understanding that when using the steam room temperature rises sharply, and then falls again. That is why the material must be resistant to such changes.

- Environmental friendliness. There are insulators that emit harmful substances during heating. Before buying it is necessary to study the composition of the product and make sure that there are no poisonous components.

Of course, an important criterion is also the cost of the material. However, you should not save money by using old ways and cheap insulators. They cannot boast of good thermal insulation characteristics, and their fire hazard is quite high.

How to properly insulate?

Now it is time to figure out how you can insulate the steam room with your own hands, so that the high air temperature is kept as long as possible. To do this, you need to make sure that any heat leaks are excluded. A step-by-step guide will help in this process.

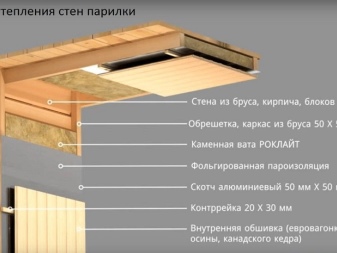

Walls

In the process of carrying out the work, close attention should be paid to the walls. It is necessary to create a thermos effect, so that the heat inside will remain as long as possible. When finishing be sure to take into account the fact that the wooden sauna two years after construction will shrink to 20 cm. No one can tell you the exact parameters, because it depends on the type of materials used, as well as on the frequency of use of the bath.

First of all, It is necessary to carefully prepare the surface of the walls before installing the thermal insulation material. Get rid of debris, dirt and dust, and then you can proceed to install the wood frame. Only after that you can start laying the film, which will provide reliable protection against steam.

During the laying of the timber walls need the use of special structural details. In other words, you need to figure out exactly how the beam can deform during the use of the steam room and how this can be dealt with.

In order to prevent linear expansion, you need to install anchoring supports.

Floor

Provide a normal thermal conductivity in the bath is impossible if you do not completely eliminate the loss of heat. And you can not do this without quality thermal insulation of the floor. Steam room is the most heated part of the building. Given the fact that in winter the ground can freeze to 1 meter, it depends on the insulation of the floor the amount of heat loss.

Under the steam room will need to dig a hole, the depth of which will be at least 60 cm do sandy base and set on it the selected material for thermal insulation. If it is sheets of foam plastic, that in addition will have to work the joints. The ideal choice for this will be mounting foam or glue.

After all the construction work is complete, you can proceed to the creation of plank floors. They must be sloped so that water can flow freely to the sewer.

It should be installed in such a way that the boards can be removed and dried if necessary.

In the process of selecting and installing material for insulation, close attention should be paid to the design of the floor. The most popular in the steam room are leaky floors, which are quite difficult to insulate. Most people make a concrete floor with a thickness of at least 25 cm, and use foam with a thickness of 20 cm as an insulating material. A floor made of expanded clay concrete is also very popular. If a similar method of insulation is carried out, it will be necessary to replace the old sand, as it can not serve as a base for the floor.

For the floor, it is worth using only high-quality materials with resistance to moisture. It is the floor takes the brunt of the load, so you need to make sure that it will not change its shape during operation.

Ceilings

Installation of insulation on the ceiling must begin before the insulation will be made. It should be noted that it is the ceiling that receives the maximum amount of heat through convection. The hot steam ends up at the base of the walls before the rooms have time to warm up.

This leads to the fact that the linings often get wet. This is why the ceiling must be covered with polyethylene foam with a special aluminum coating. And in order to ensure that the condensate does not flow down the thermal insulation, it is necessary to lay the film on the walls.

Thermal insulation of the ceiling should begin with eurowood. The ceiling is uniquely shaped so that there is always a small gap between it and the insulation material. This allows the vapors to escape from the inside and has a positive effect on the longevity of the product.

Some owners of the steam room simply trim the ceiling with moisture-resistant plywood, on top of which a small divider lath is nailed. With insulation must be extremely careful. An excellent solution for this will be stone wool slabs, the thickness of which is at least 60 mm.

It is best to insulate the ceiling in two layers. This prevents the appearance of gaps at the joints, through which the water vapour escapes. If it will accumulate, it can cause bacterial growth and the emergence of unpleasant odors.

Once the insulation is installed, it should be carefully covered with timber. Close attention should be paid to places where there may be holes. The best solution is to glue the places with special heat-resistant silicone. Thanks to this you can not doubt that the heat will remain inside the room of the bath.

Recommendations

In order to achieve maximum results in the area of insulation of the steam room, it is necessary to follow some recommendations.

- Pay close attention to the design of windows. Reduce heat loss from the window is difficult enough, so it is best to provide for this point at the design stage. Windows should be made small, and the openings and soffits should be insulated as much as possible. In addition, it is worth installing windows as low as possible, so that the hot air does not touch them.

- The doorway should be small, and the threshold should be high. This will prevent the outflow of warm air and the inflow of cold air.

- The power of the furnace should be such that it fully corresponds to the size of the room. It is also very important to put a sufficient number of stones in the sauna heater. This will not only speed up the heating process, but also increase the heat output of the brick.

Thus, the process of insulating the steam room is quite complex and involves many nuances. In order to achieve the highest quality result, you need to pay close attention to the choice of materials, as well as competently lay them.

About how and what is better to insulate the sauna, you can learn from the video below.