Options and technology of insulation of ceilings in baths

When building a bathing structure, it is important to remember that a cold roof will not be able to retain the level of heat that is formed during the reception of bathing procedures. It follows that the ceiling must be insulated. To date, for these purposes, developed a lot of building materials. It remains only to choose the most acceptable option.

Features

Quite often, visitors to the steam room are faced with the emergence of condensation. It is formed when the hot steam rises to the maximum height, and in the room itself there are a large number of drops. It makes no difference whether the steam room is built in or plays the role of a separate structure. In any case, it is necessary to make insulation of the ceiling. And then there is the question of how to do it, what materials should be used.

If the steam room is built in, the heat retained inside penetrates into the living house. To prevent this from happening, you need to create a heat chamber.

Traditionally, wood is used for finishing baths. However, wood is the hardest to resist the aggressive effects of high temperatures and damp conditions. That is why the created coating of insulation must be of high quality to provide a comfortable microclimate in the steam room.

To ensure that the wooden elements installed in the baths served their owners for many decades, they must be impregnated with special compounds. On the one hand, this measure is justified - wooden parts do not swell from moisture, remain as strong. However, under the influence of high temperature, the chemical coating begins to emit toxic fumes that can negatively affect human health. But if you do the right insulation inside the structure, it will be possible to save the wooden structure from the occurrence of condensation.

The procedure for good insulation of the ceiling in the sauna structure or freestanding steam room involves compliance with certain rules:

- steam must form and remain inside the room;

- The inside of the ceiling must be protected from high humidity;

- it is important to prevent the appearance and accumulation of condensation not only in the steam room, but also in the ceiling and wall slabs.

To date, many materials have been developed that can be used as insulation. However, not all options are suitable for baths. For example, plastic - under the influence of high temperatures, this material is subjected to deformation; plywood or fiberboard expand, change shape and accumulate moisture inside themselves.

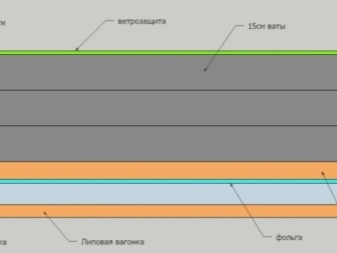

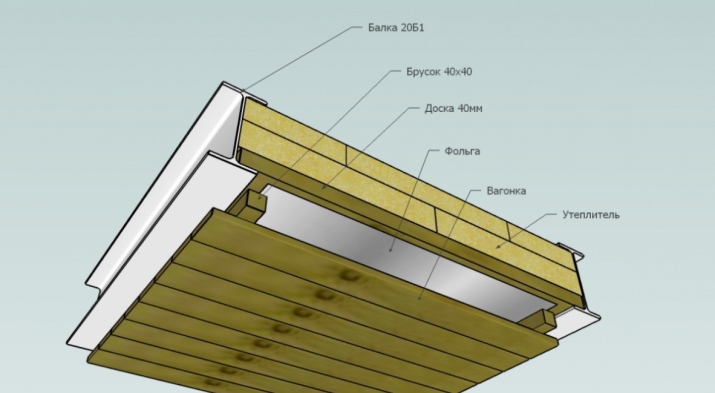

According to experts, the best way to insulate is to install a ceiling slab in several layers:

- The first layer is laid insulation, which prevents the penetration of moisture;

- the second layer is insulation;

- the last layer is aluminum foil.

Thanks to such multilayers ceiling slab easily keeps heat and for a long time does not allow the steam to escape.

Modern versions of insulation are divided into several types:

- fibrous;

- lamellar;

- block;

- backfillable;

- tile.

Among other things, insulation is divided by composition:

- organic;

- inorganic;

- polystyrene foam;

- technovent and technoblock.

Whichever insulation is chosen, it must have certain qualities.

- Heat resistance. This property gives a guarantee that the material will not spontaneously combust.

- Eco-friendliness. When exposed to high temperatures, the material should not emit vapors and substances hazardous to humans.

- Airiness. In simple words, the material should prevent the collection of water and accumulation of condensation.

- Resistance to humid environment.

What is the best insulation?

When creating thermal insulation of the sauna ceiling, you can use any material. Adherents of the good old traditions prefer the "grandfather's" way, which involves the use of almost free elements.

Others, on the other hand, trust more modern options for insulation - for example, polypropylene foam. This material is quite lightweight, has a foil coating, ideal for insulation of bath complexes. The presence of foil in the design of this material is considered a definite plus. Thanks to it foamed polypropylene not only retains the arising heat, but also reflects it in the opposite direction. With this material it is possible to reduce the resources spent on heating the room by almost 3 times.

To achieve higher efficiency, foamed polypropylene is used as a complex insulation, on top of which mineral wool is laid. By the way, the material can be used to insulate the walls of the bath outside.

Other owners of sauna complexes stop their choice in favor of foam insulation. It is quite interesting and very budgetary material insulation ceiling, which has many advantages. For example, it is an excellent noise insulator. Spraying foam insulation is done from inside the attic with a special device, which allows for a short period of time to fill the ceiling even in hard-to-reach places. The only disadvantage is that you have to rent special equipment for the work, as it is not reasonable to buy it for a single job.

Recently, the owners of bath structures began to give their preference in favor of such a thermal insulation, as growing aerated concrete. This material is characterized by low thermal conductivity and excellent noise insulation. In addition, growing aerated concrete is environmentally friendly, fire-resistant, long service life, resistance to moisture, and most importantly, has a low cost. For the arrangement of this insulation, it is necessary to make installation of a stationary formwork on the attic side. It is best that it was made of glass magnesium sheets.

But this is not a complete list of insulators that are used for finishing the ceiling of the bath complexes. The most popular among them are mineral wool, expanded clay, ecowool, and, of course, the "grandfatherly" method, which involves the use of cement and lime. Some people as an analogue of these components uses earth, clay and sand, but the wrong formula for combining these substances leads to unpleasant consequences. Someone prefers to insulate the walls and ceiling of the bath penoplex - the main thing is to choose the correct dimension and density of the material.

Minwata

Most often, mineral wool is used as a heater. It has a fibrous structure, externally reminiscent of the most common wool, sold in pharmacies. When creating this material, a crushed mixture of some rocks is added to the composition. That is why it gets the structure of fiber. Mineral wool is popular because of a reliable list of qualities:

- long service life;

- excellent hydroscopicity;

- refractoriness.

It is worth noting that to work with mineral wool must be equipped with a tight suit and rubber gloves. Otherwise, in contact mineral wool with the skin a person gets irritated and itchy, to get rid of which will help only thorough washing.

Styrofoam

Many people are used to the fact that foam plastic is an excellent insulator for all types of structures and constructions. However, when insulating a sauna complex or freestanding steam room foam should be refused. When heated, this material begins to release harmful substances that adversely affect human health.

Claydite

Many fans of houseplants are used to the fact that expanded clay plays the role of drainage. But in fact, its properties have a wide variety.

In appearance, expanded clay resembles stones, but if you look closely, you can see that they have small pores. They just absorb the resulting moisture.

Claydite has many important advantages:

- environmental friendliness;

- fire resistance;

- long service life;

- low cost;

- ease of use;

- antibacterial.

Claydite insulation suggests the use of a set of vapor barrier and waterproofing materials.

Sawdust with cement

This method of insulation was used in the distant past. However, Adherents of the old traditions even today practice this option of insulation. To prepare the mixture you need to take 10 parts of sawdust, 1 part of lime or cement. Then add 1.5 parts of warm water, mix everything thoroughly - and you can begin the work.

The solution should be evenly spread over the surface, filling even hard-to-reach places. The presented composition of the insulation is economically advantageous, and environmentally friendly. The disadvantages include only the complexity of preparation, low level of thermal insulation and lack of protection against mold.

Ecowater

Thanks to ecowool, it is possible to keep heat in the room for a long time. This material is environmentally friendly. Its fibrous composition is made of cellulose, in which additional substances are added to improve the basic functions. Ecowool becomes resistant to fire, prevents the emergence of bacteria, insects and rodents. But the most remarkable thing is that this material is easily spread over the entire area of the ceiling slab, filling even hard-to-reach voids. The only disadvantage of ecowool is the absorption of moisture, due to which the thermal insulation properties are slightly reduced.

Layout of insulation for different ceilings

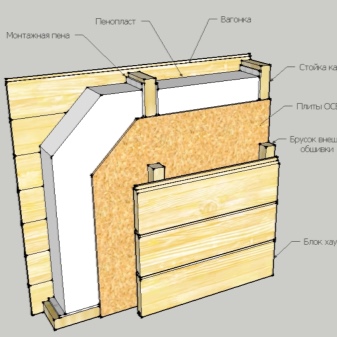

Before you start working on the insulation of the ceiling of the sauna building, it is necessary to determine the structure of the roof. Designate whether it has an attic or not. From a structural point of view, a great similarity are log and panel buildings. They also have a vapor barrier and sheathing. On the walls and on the ceiling, a vapor barrier is installed. Next, beams and a layer of insulation are installed. You can use basalt wool. But over it again have to pass a layer of vapor barrier. And only then the timber is installed, and the battens are fastened.

As for the size ratio, the ideal is considered beam 40 mm and insulation of similar thickness. Use a large amount of insulation is not recommended. Overconsumption of the material will be inappropriate, its properties will be performed exactly the opposite.

On the ceiling slab it is necessary to create a slight slope where condensation will collect. Thus, there will be a space under the battens, giving the bathhouse a chance to dry out.

If there is no attic, it is right to do a few other things. Coat the battens with a 2 cm layer of clay, and on top of the mix of cement and wood chips.

If the owner wants to insulate the ceiling overlap according to all the rules, then he should worry about the vapor barrier of the ceiling. It is required to create a vapor pocket that reaches to the top of the doorway. Today, thermal insulation of the ceiling without the use of foil is considered ineffective, as the steam room will not perform the required functions.

To date, there are several known technologies for insulating the ceiling overlap. And each allows you to cope with the effect of a cold roof. The only thing is that not every method of insulation can be done with your own hands. In some cases, you have to call in a specialist.

Panel

Insulate the ceiling, not having experience in this area, is very difficult. And even calling for help from friends, to cope with the task at hand, most likely, it will not be possible.

First of all, to create a panel insulation is necessary to make a special design. Then it is fixed on top of the beams.

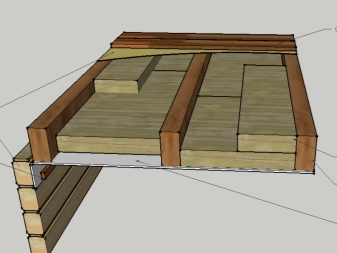

Next it is proposed to see the step-by-step process of laying out the insulation:

- on the floor supports close to each other boards are laid out;

- From the inside are fixed narrow boards that play the role of edges;

- a vapor barrier film is laid;

- in the appeared space ecowool or any other heat insulation is laid;

- a polyethylene or ruberoid film is laid;

- The last step of insulation is to install boards that will play the role of the attic floor.

Underlayment

In order to create this coating, it is necessary to worry about the installation of beams in advance. On them are laid boards or shields. The created structure is insulated with fiber material.

The very process of laying insulation is carried out in several stages:

- GIP (waterproofing film) is laid overlapping on the beams on the roof side;

- on top of waterproofing boards or plywood;

- Mineral wool is placed in the gap between the beams;

- install the vapor barrier at the bottom of the beams;

- the timber battens are fastened;

- At the very end the linings are installed.

When the work is completed, not only is the ceiling ceiling insulation obtained, but there is also an additional place to store old things.

Decking

Today, the flooring ceiling is quite rare. More often a hewn round bar is used. In the recent past, this method of insulation was considered the most profitable. It was enough for a person to go to the woods and chop the necessary material for construction himself. Today the picture looks different. You will have to spend a large sum to purchase the necessary amount of wood required.

To date, there are several options for installing insulation:

- Along the felled wreaths;

- Using unedged boards;

- insulation is laid on the beams of the floor;

- The carrier lath frame is used as a basis for laying the insulation.

The very process of work takes place in several stages.

- On the floor of the attic room is laid vapor barrier film.

- On top is placed mineral wool. As an analogue, you can use expanded clay or a mixture of sawdust and clay.

- The last stage requires laying the waterproofing film on the surface.

Useful tips

If the owner of the sauna decided to independently perform insulation of the ceiling ceiling, he needs to take into account some factors and pay attention to the ceiling, located above the steam room. If even the slightest mistake is made in the process, heat will quickly leave the room.

To avoid any problems, it is important to listen to the advice of experienced experts. They argue that in the process of working with vapor barrier elements or foil must be extremely careful. This material is very fragile and can accidentally tear. Accordingly, it is impossible to use a damaged piece in the insulation technology.

For the proper laying of materials, it is preferable to start a little lower than the walls. This leaves a free space that allows you to put loose mixes or lay mineral wool.

Those who have decided to insulate the ceiling of the bath with a mixture of clay and sawdust, you need to know how thick the layer should be. For the operation of the bath in summer, the thickness should be 5 cm. If the bath will be used in winter, the layer of insulation should be 15-20 cm.

In the case of creating a ceiling slab of logs on the side of the bath is required to create a crate. It is covered with a vapor barrier and covered with a layer of sand. Only after that you can proceed to the insulation according to the chosen technology.

If the owner of the bath has no desire and opportunity to buy a vapor barrier and waterproofing, it is necessary to use high-tech insulation, which are made on the basis of mineral wool and have a foil coating. With such material, the use of any additives is not required.

The main thing is that for the insulation of the ceiling overlap in no case can be used foam plastic. Yes, this material is often used as an insulator of other buildings. In addition, it has a low cost. As already mentioned, when exposed to high temperatures, foam plastic emits harmful substances that adversely affect human health.

Another important tip from the experts - do not pay attention to insulation materials with low cost. A suspiciously low price indicates their poor quality.

The following video describes the vapor barrier and insulation of the ceilings of the bath.