All about insulation of a bathhouse floor

For foreigners, a bathhouse is a place where you can thoroughly wash yourself. And for Russian people it is a real sanctuary, so to speak, a temple of steamy bliss, where you can rest not only the body, but also the soul. It is very important that the bathing structure be made according to all the rules of construction. In simple terms, the room must retain the heat it creates. Otherwise, visitors will not be able to experience a sense of comfort. Therefore, it is necessary to create effective insulation on all sides of the bathing structure, and especially the floor.

Materials

When the era of bathing procedures about the insulation of floors in the bath rooms, in principle, did not think about. And there are several explanations for this. First, many people installed in the bathing complexes spilled floors. Accordingly, used water flowed through the gaps between the boards. Secondly, heat loss occurred due to a loose connection between the roof and walls. Thirdly, at the time of the emergence of baths were not invented thermal insulation materials. And the last reason - unpretentiousness of society. At that time, people were satisfied with small benefits and much more tolerant of the demand for comfort.

Today, the time of the hard floor is over, but some followers of tradition give their preference in its favor. And yet most people opt for modern options for creating a warm floor.

In the construction of baths these days, special attention is paid to the insulation of the floor. Carefully choose the material that corresponds to the main characteristics of the frame base. Flooring in modern bath structures is made of concrete or wood, the surface of which is covered with a special finish. But this fact does not prevent specifying a list of basic insulation materials.

Polystyrene foam

This option of insulation is considered universal. Over the past decade, it has become widespread. It is used in the construction of home baths and the construction of commercial bathing facilities. The structure of polystyrene is very rigid, with a sharp cutting tool can be cut without any breakage and uneven cuts. Closed granules, which are present in the composition of this insulation, are responsible for the moisture resistance of the material. This means that Styrofoam can be used for laying any floor, even under tiles. They can be insulated floor in the steam room, washing room, pre-bath. In general, along the perimeter of the sauna complex.

Mineral wool

This material is ideal for insulating concrete floors. However, in the arrangement of the bath with wooden floors, it is necessary to take enhanced measures for the installation of insulation. Experts say that in terms of hygroscopicity, basalt wool is considered the best.

Foamed polymers

These materials are suitable for filling joints, screw pile grooves and various cavities that are often present in the construction of wooden floors. Distinctive features of polymers - a specific weight, low load on the bearing parts of the structure and a pleasant cost.

Claydite

Ceramic pebbles, which gardeners use as drainage, can become an excellent insulator for the floors of an entire bath. The only thing that does not suit the craftsman is the monotony of filling the space with expanded clay pebbles. A thin cement-sand screed is used to bind the pebbles.

Perlite

This material is part of the insulation composition, which also includes high-quality cement and water. When the elements are combined, a gas-forming chemical reaction occurs, and after drying, the inner part of the layer becomes porous.

Alternative insulation materials

When insulating poured floors, you can use polpan. This material has a fairly high price, but is distinguished by its high insulating properties. Foam concrete also has excellent characteristics.

It can be used as a structural base and floor design. Some home bath owners use boiler slag as insulation.

Its laying is carried out according to the technology of using expanded clay. Some insulate the floor with foamlex, others with foam plastic, and others use the "grandfather's method".

Rules and methods

The choice of the method of insulating the floor covering depends entirely on the structural features of the structure and the foundation. For example, a steam room. If this room stands on the open ground, as a heater should not be used absorbent material. Ideally, it is necessary to make a screed and waterproofing.

If the sauna stands on stilts, the bottom part of the insulation is created from a vapor-insulating material and a waterproofing membrane. This film collects moisture and drains the liquid to the drainage funnel.

In the case of, When the floor of the bath is made of wood, and the structure itself stands on the ground, it is best to use extruded polystyrene foam as an insulator. It does not allow steam to pass through. When laying the sheets are in tight contact with each other, they lie on the ground, covered with polyethylene. The top layer consists of waterproofing and boards. When gluing the sheets of polystyrene foam, it is desirable to use polyurethane adhesive. If the thickness of the sheets is 5 cm, then the bottom layer of polyethylene can in principle be abandoned. But in this case you will have to create a gravel-sand cushion, which will protect the wooden floor boards.

The floor, where the steam room is located, can be additionally insulated with mineral boards.

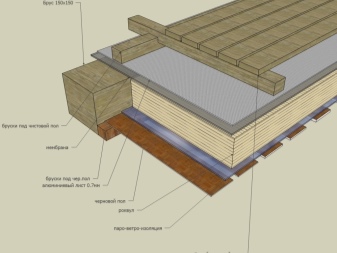

Many owners install bath structures on the foundation of pole pillars or piles. Thus, it is possible to avoid rotting of the base and the lower edges of the walls. Just in this situation, the floor is built on joists. Extruded polystyrene foam or polystyrene foam can be used as insulation. Foam is used at the joints between the boards and the beams.

As an alternative, mineral wool is assumed. But in this situation, there should be a gap of 10-15 cm between the floor and the insulator.

It is much easier to use perlite concrete on top of the concrete floor base. Perlite is added to the cement mortar, pre-wetted with ordinary water, and a little liquid soap. The mixture acquires a viscous structure and is poured as an insulating layer, the thickness of which should be at least 12 cm.

Much more difficult to perform, but of higher quality is the concrete floor, covered with a laid insulating layer of extruded polystyrene foam. On the laid out sheets of insulation, a film is laid and beacons are glued.

It's no secret that the concrete floor is only a rough base that provides the required level of comfort. But do not forget about the waterproofing of the surface layer of the floor and communications.

How to insulate with your own hands?

By arranging the floor insulation in the steam room and other rooms of the sauna complex, the system of drainage of groundwater is not worked out. This is solved with the help of drainage, laid along the entire perimeter of the structure.

In this case, the builders know the exact technology of their work. They understand what should be focused on. A person who is not strong in the construction sphere, should be guided by the instructions. It is necessary to insulate properly, otherwise there is no point in the work.

To begin with it is necessary to dig a part of the ground inside the structure. Its depth should not be less than 15 cm. The excavated mass is replaced with expanded clay or crushed stone-sand mixture.

This option of insulation is considered softer. The laid out layer should be leveled on the exposed slats.

The next step is the design of the cushion. A film is laid, on top of which the main insulation is laid - Styrofoam or extruded polystyrene foam.

The third step is to pour the screed and apply waterproofing. Tile is laid on the concrete base, but many users recommend abandoning it. Some argue that tile cools the heat created in the bath, while others consider the issue of safety. As an alternative, wooden ladders can be laid on top of the tiled floor, thereby the floor acquires additional advantages:

- excellent waterproofing and a warm floor;

- no ground odors;

- ease of cleaning the sauna room.

Adherents of good old-fashioned traditions give preference to "grandfatherly" methods of insulation. One of them - dousing the cold floor with boiling water. But this procedure is exhausting, as it is required to pour the floor until the furnace heats the basement.

The floor of a stone bath is insulated with a mixture of grated clay and chopped reed stalks. Oak sawdust is used to protect the insulation from soaking.

Wooden

If you want to insulate an already finished wooden floor, you will initially have to dismantle the upper flooring. Otherwise, it is necessary to follow the proposed instructions and do not deviate from it a single step.

- After dismantling, check the wooden elements. Damaged parts are replaced by new timbers.

- The lower edges of the joists are lengthened, thereby creating a support for the rough slab.

- A roughing layer is formed of budget lumber. A gap of 1 cm should be left between the boards and the joists.

- A rough floor is created from wooden scraps, gaps are left to prevent deformation of the floor from temperature effects. The scraps are laid on the joists.

- If there is ground water under the sauna, it is necessary to form a vapor barrier. It should cover the rough finish of the floor along with the joists. The height of this layer should not be less than 15 cm.

- If the waterproofing material is presented in a roll, it must be laid overlapping, the ends are fixed with tape.

- The distance between the joists is filled with thermal insulator. If the thickness of the insulator is close to the finish covering, it is necessary to put a ventilating purlin with a step of 40 cm on top.

- Lay an additional layer of waterproofing to prevent moisture from getting onto the thermal insulator.

- Installation of boards, cutting the edges of the thermal insulator, fastening skirting boards.

Concrete

The procedure for insulating concrete floors is carried out after the laying of a rough layer - screed. Next, it is necessary to follow the step-by-step instructions.

- On the rough screed, waterproofing is laid. It is possible to use durable polyethylene. The film is spread over the floor, touching the walls for at least 5 cm, we can then cut off the excess.

- Thermal insulation material is laid. In the form of insulation foam plastic will do. To fix the boards, we form a frame of wooden bars, which are attached to the floor with the usual self-tapping screws.

- Pour the fixing mortar, with a reinforcing mesh laid on top.

- After the drying of the mortar is poured leveling screed with a thickness of 5-8 cm and left to dry out.

Common mistakes

When independently insulating the floors in the bath room, inexperienced people make many mistakes, due to which the warm air cools or disappears. The most common is considered a wrong use of insulation material. It is suggested to consider this issue on the example of mineral wool. It is presented on the shelves in the factory packaging. In this form it should be stored prior to the start of insulation work. Mineral wool can be unpacked a day before laying. This should be done in the bathhouse itself or on the porch under a canopy. In this way it will be possible to protect the material from moisture, which negatively affects its properties.

As soon as the insulation is laid, on the base of the floor must immediately begin installation of the next part of the floor covering.

The second common mistake is the deformation of the compressed material and large gaps between the sheets of insulation. Under compressed conditions, the insulation loses its properties. And cold bridges form in the gaps. To get rid of the gap between the sheets of insulation foam will help.

The third mistake is the lack of assessment of the state of the floors. We are talking about the presence of mold on the floors and in general the dilapidation of individual boards. Such floors should be replaced.

The fourth mistake is the lack of treatment of the wooden structure of the sauna structure floor. Each board should be covered with an antiseptic compound. This is the only way to guarantee long life of the wooden floor base, absence of fungal deposits and mold.

With the fifth mistake faced by many people who have decided to insulate the floor in the bath with their own hands. It lies in the wrong thickness of insulation. Too thin material will not provide any effect. So, a layer of mineral wool should be 14 cm, sawdust-concrete - 18 cm, and expanded clay aggregate-concrete at all 27 cm.

The sixth mistake is much rarer, and yet some craftsmen make it. They forget about the waterproofing. Before you build any building, you should check the level of groundwater. If they are close to the floor waterproofing is done in the first place.

The seventh mistake is the use of waterproofing membranes. Many believe that this material will help protect the insulation from moisture coming from below. And, in principle, this is a correct judgment. However, no one cancelled the condensation of moisture.

This process will still occur in the insulation layer. For this reason, waterproofing must have a diffusion structure that allows moisture to escape to the outside in the form of vaporization.

The eighth mistake is considered a violation of the layers of insulation. In no case should not be allowed to violate the technology of insulating the flooring of the bath. All layers must be laid in a clear sequence. Thermal insulation must adjoin closely to each other or go sheet to sheet. Properly composed "pie" guarantees the maintenance of heat in the bath room.

How to insulate the floor in the bath, see below.