The variants and technology of heat insulation of frame baths

Any frame structure requires quality insulation. Especially if we are talking about the bath, in which the heat must be preserved for a long time.

What can be insulated with?

When choosing a thermal insulation, you should consider not only the thermal insulation characteristics, but also the resistance of the material to conditions of high humidity and high temperatures. Another indicator - environmental friendliness. The insulation when heated should not emit an unpleasant odor or toxic compounds. The following materials are used to insulate frame structures.

- Plates based on basalt fiber. Do not burn, have excellent thermal insulation properties, are environmentally safe, since natural materials are used for the production: basalt, limestone, quartz. The small size and lightness of the material ensures easy installation. The boards fit tightly to the base, eliminating the appearance of "thermal bridges". Do not lose their properties even when exposed to high temperatures, are versatile, suitable for insulation of walls, floors and ceilings.

- Mineral wool. It is better to choose mineral wool in mats. This material is more plastic, it does not break or crumble during installation.

- Glass wool. Inexpensive material, good heat retention, does not burn. Disadvantages: "dusty", the fibers settle on the skin, causing itching. Therefore, to work with glass wool must wear protective clothing and a respirator.

- Slabs of reed. Ecological and natural material with a thickness of up to 100 cm. One layer is enough to provide good insulation, so reed boards are often used in frame construction. Disadvantages: the material burns, is subject to rotting, retains its operational properties at humidity not exceeding 70%, so it is suitable only for external insulation of walls.

- Sawdust-gypsum mixture. It is easy to make yourself: you need to mix sawdust (suitable fine and well-dried) with gypsum or cement in a ratio of 10: 1.

You can add lime to the mixture to protect the homemade insulation from rodents.

- Thermal insulation with foil. Material based on basalt or mineral wool with a protective vapor barrier layer of foil.

- Synthetic insulators: foam plastic, polystyrene foam. On the merits: excellent insulation properties, resistance to high humidity, light weight. Of drawbacks: the material emits toxic substances when heated, so Styrofoam plates can not be used to insulate the steam room and the walls adjacent to it.

Tip: Styrofoam is better to insulate the structure from the outside, since the internal insulation is displaced dew point, and the condensate will be formed from inside the wall. This option is well suited for winter.

With temperature fluctuations, freezing/thawing condensation will lead to rapid destruction of the material.

Arrangement of vapor barrier

If we talk about basalt boards, after getting wet, they completely lose their thermal insulation properties, become heavier and simply "slide" down. It is impossible to dry them. Styrofoam boards are not afraid of water, but with high humidity mold and fungus will form on the surface. Wet insulation is a threat to the frame itself, if it is made of wood. Over time, wooden bars will begin to rot.

As a vapor barrier is used:

- films with a foil base: they will not only protect the insulation from steam, but also keep heat;

- Dense polyethylene (greenhouse film);

- inexpensive and environmentally friendly asphalt felt;

- special membranes of non-woven fabric: they are expensive, but will reliably protect the insulation from the effects of steam

- Vapor barrier reinforced membranes (prior to installation, be sure to study the instructions from the manufacturer).

Another popular material - roofing felt. Perfectly protects insulation, inexpensive. But when heated smells, emits toxic substances, so use it as a vapor barrier is still not worth it.

Step by step instructions for insulation

It is worth a step by step study of the stages of insulation of a frame bath with their own hands to do everything right.

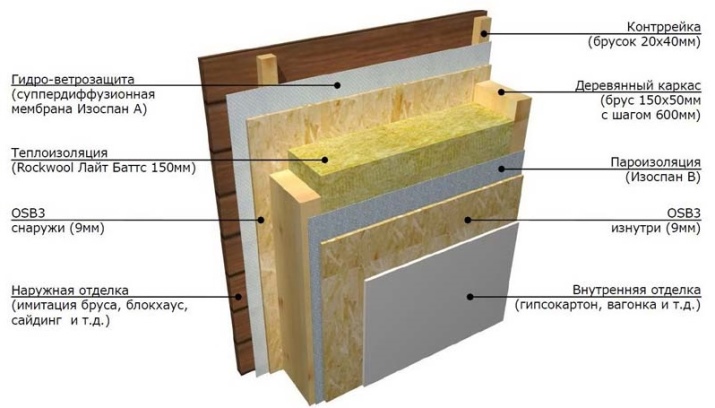

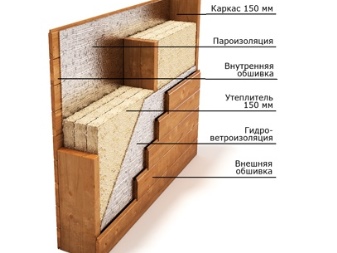

Walls

Thermal insulation of a frame bath begins with the construction of the walls of the building. When using this method of thermal insulation, the material performs two functions: insulation and support, that is, it acts as a building material. Thermal insulator is laid between the load-bearing walls of the structure. On top of them laid layers of vapor barrier. The result is a construction of several layers, resembling a pie. The insulator is the main part of the structure and occupies the central part. It is worth noting that it is covered with a vapor barrier on the inside and a waterproofing on the outside.

Most often, the outer layer is not made, since it appears during the decorative cladding. Therefore, the sheathing itself can be considered an element of thermal protection and support, which increases the strength of the structure. Usually consumers prefer to put at least 2 layers in the frame of the bath. At the same time, the materials from which the insulators are made are different. One should be tile, and the other - roll. Builders claim that the OSB pie will not contain gaps, and therefore the heat protection will be better. When laying insulation, pay attention to the side of the material. Incorrect laying can lead to poor bath performance.

Near the furnace, the protection of the insulation and the walls should be strengthened, since they will be exposed to high temperatures. Mostly asbestos boards and cloths are chosen for protection. Many people believe that asbestos is detrimental to human health, so they look for other protection options. Fortunately, there are now many modern protective products. For example, basalt fabrics and needle-punched mats, isolones, etc. These materials are very resistant to high temperature (200-450 degrees) and safe for humans. There are two ways to mount a refractory furnace:

- On a layer of decorative cladding;

- On top of the vapor barrier layer.

It is necessary to choose correctly the material for the vapor barrier. Many people mistakenly think that such an inexpensive material as polyethylene film will do the job. But it will melt under the influence of high temperature. The most common and effective material is aluminum foil. For tightness, it is recommended to glue it with heat-resistant adhesive tape. Do not forget that heat escapes not only through the walls, but also through the ceiling and floor. It is logical that in these places there should also be insulation.

Flooring

At the stage of laying the floor, it is worth thinking about its thermal insulation, as in the future this will bring additional problems and money costs. It is necessary to follow a clear order of work for maximum thermal insulation:

- At the first stage, a screed base is poured on the ground prepared in advance;

- then it is necessary to lay a layer of waterproofing, the materials can be as a roofing felt or thick polyethylene;

- lay a layer of thermal insulation, the materials can be used the same as for thermal insulation of the walls;

- then one more layer of waterproofing should be laid, the upper one;

- Finally, the second layer of concrete screed shall be poured.

To increase the service life of the sauna floor, after full hardening, builders are advised to treat it with a waterproofing solution. This procedure will not allow moisture to penetrate into the cracks of the concrete. Even the smallest drops of water destroy the floor and disrupt the thermal insulation.

Ceiling

The ceiling is insulated in the same way as the walls. Thermal insulation materials are similar. Procedure:

- A layer of waterproofing is fixed on the ceiling slab;

- The second layer is placed a thermal insulator;

- the third layer - vapor barrier;

- The last layer is a decorative cladding, which will also participate in the preservation of heat.

When insulating the ceiling, you need to remember one important nuance. Earlier we wrote that on the walls there should not be a free space between the layers of vapor barrier and cladding. In the ceiling, however, you can not remove this cavity. The steam will rise up and the sheathing will get wet. The cavity left will help the decorative layer to dry more quickly.

Building a frame bathhouse is the right solution for many cottage areas. This concerns not only the speed of the process, but also the money spent. You can also note the joint construction of walls and insulation. This method helps to save time.

When insulating a frame bath, it is necessary to immediately choose the technology of thermal insulation and directly the material itself. This method will achieve a better quality of construction and the right microclimate in the room.

In the following video you will find the technology of insulation of frame baths.