All about insulating baths from inside

Knowing everything about insulating baths from the inside is extremely important for anyone who has decided to build and equip his dacha plot. High-quality insulation of the walls inside with your own hands according to the step-by-step instructions will not only reduce energy losses, but also allow the structure to stand longer. You can use claydite block insulation and other options, but the main thing is to do it the right way.

Materials

For thermal insulation is quite often used penoplex. Such material is in demand very widely. From a technical point of view, this is expanded polystyrene, which is subjected to extrusion. Thermal insulation properties of this material are quite sufficient to successfully solve problems. Foamplex has a smooth and even surface, which significantly increases the adhesion to various other materials. It is also worth considering the incompatibility of foamlex with "wet" finishing of the building.

It is also necessary to pay attention to the fact that the foamlex is not placed according to the same technology as the usual polystyrene foam. But it is compatible with a variety of construction materials. The main properties of this option of insulation:

- high strength;

- minimum moisture absorption (including in the form of steam);

- ease of installation;

- relatively comfortable price;

- no allergic risks;

- elimination of rotting;

- minimum likelihood of damage;

- flammability;

- low flammability;

- destruction in contact with solvents;

- low permeability to steam flow.

Foam plastic can also be used to insulate the bath. This is the most budget-friendly option of mass-produced materials. It is resistant to moisture and is suitable even for the wettest areas. Styrofoam is relatively lightweight, which prevents excessive load on the foundation. It will be possible to avoid complicating the foundation work.

The thermal conductivity of foam is 23 times lower than that of full-fledged brickwork. But it should be understood that all the advantages of this insulation crosses its lack of environmental friendliness and excessive health hazards. A slight increase in temperature is enough for the release of styrene. This substance is extremely dangerous for the human body, especially for normal blood circulation.

It is also necessary to remember that when foam plastic burns, it releases phosgene, a gas that in the past was used as a full-fledged weapon.

It is also worth to deal with another widely recommended material - mineral wool. This insulation is not susceptible to moisture, although it is excellent water vapor permeable. There is air circulation through it, which makes it much easier to maintain the necessary microclimate in the house. In addition, mineral wool is also an excellent noise insulator. The latter property is very important when you have to build a bath near an industrial facility, road or railroad.

To properly assess the prospects of using mineral wool, it is necessary to consider other properties such as:

- increased resistance to fire;

- long period of use;

- Relatively low concentration of toxic resins (which can be neglected, but only when using quality products from reputable suppliers);

- The need for special treatment to reduce hygroscopicity;

- Rather substantial weight (transportation and installation is not as easy as it seems).

How to choose insulation?

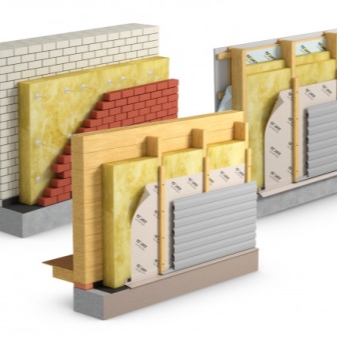

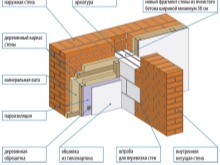

A very important point - which insulating material is better for a stone or brick sauna. The use of brick does not cause any doubts - it is necessary to insulate the building, otherwise the heat loss will be excessively large. It is quite common to insulate with plaster applied from the outside. But you can also apply the construction of an additional wall of timber. But it does not cancel the need to apply the internal heat-saving finishing.

For insulation of a brick bath can be used:

- basalt board;

- mineral wool;

- expanded polystyrene foam;

- FPU;

- Various organic insulators (now used mainly as a backup, in addition to the main circuit);

- polyethylene foam;

- magnesium oxide with acrylic resin.

The most traditional option for insulating brick bath structures is the use of mineral wool. If the masonry is made in one brick, a layer of at least 0.1 m will be required. For places with a particularly harsh climate, this figure will be even 15-20% higher. Important: in this variant the insulation is made strictly from the inside. Fans of new modern technologies can focus on the use of Rockwool boards and similar structures.

Quite often there is a need to insulate a bath from foam blocks or from expanded clay aggregate blocks. In terms of thermal insulation, there is no particular difference between them, so that the association is fully justified. In this case, it is quite logical to use the same mineral wool. But it is not recommended to use glass wool for internal insulation, especially in the area of the furnace. This material does not tolerate strong heat, and quickly loses its valuable properties.

A good alternative solution can be considered safe and quite natural felt.

This is a durable material, practically not prone to the emergence of mold. Through it will be a good way to remove excess moisture from the room. To insulate the horizontal surfaces of the bath can be used and expanded clay. But its laying in the walls is not appropriate - shrinkage over time is likely. For external insulation of penoblokovyh structures can zakazuetsya foam. It is excellent for plastering, which enhances decorative qualities and provides additional protection.

Quite often there is another question: how to insulate an old wooden bath. After all, over time, previous insulation solutions lose their characteristics, even if they were once impressive. The approach is basically the same as that used to insulate fresh wooden buildings. Lovers of natural materials should pay attention to:

- peat;

- jute;

- expanded clay;

- linen fiber;

- oakum.

Of the new materials, it is useful to choose non-combustible boards on a mineral basis or gypsum fiber. It is worth saying that for the rest room, the options are much greater than for the steam room. There is no longer required mandatory resistance to heat (although resistance to open flame is still important). In general, the criteria for choosing between any insulation materials will be:

- Resistance to moisture (relying on exterior waterproofing alone is unwise);

- stable preservation of the original geometry and volume;

- environmental and sanitary safety;

- ease of installation;

- combinability with the used finishing and structural materials;

- low susceptibility to the formation of fungal nests, eating by rodents;

- last - suitability for installation on the crate and a good price.

How to properly insulate?

Walls

Step-by-step instructions for insulating the bath from the inside begin to be carried out at the moment when the rough building structures are ready. Technologically, it is more correct to mount the thermal protection first on the ceiling, but it is the walls that will have to pay the most attention. Therefore, it is worth starting with their consideration. For the work you will need:

- screwdriver (it is unreasonable to screw in a mass of fasteners by hand);

- hand saw;

- an ordinary joiner's hammer;

- timber;

- aluminum construction foil;

- lime or aspen linings;

- polyethylene film;

- means of protection against corrosion;

- building level (choose according to your taste);

- material for thermal insulation proper;

- masking tape;

- screws, nails and other basic fasteners.

When insulating the walls, it is necessarily necessary to arrange the inputs of ventilation. All strips and bars used to fix the materials, coated in advance with substances that inhibit the spread of moisture. Using laths is preferable because they are less likely to deform under the thermal changes. A foil or a membrane with a foil layer is mounted on the laths with a stapler.

Insulating coating is laid with overlapping, it is recommended to close the joints with a special tape or tape, and at the end of the insulation itself is made the final lining with a certain gap (at least 20 mm).

Floor

When you do the interior decoration with their own hands do not forget about the floor. It is he most often becomes a conduit for the cold. And this is not only unpleasant, but also potentially dangerous to health. Inside the floor is usually advised to fill in expanded clay. There, unlike the walls, its gradual settling is not too dangerous - and in addition, expanded clay is light (reduces the load on the foundation) and environmentally friendly.

When forming a wooden floor claydite saturate gaps logs. If you have chosen to pour concrete, insulation is laid out in layers. The optimal method is as follows:

- Wait for the first level of the pour to harden;

- Pour at least 0.1 m of expanded clay;

- lay out a steel grid for reinforcement;

- on top of it do the second level of concrete pouring;

- level the floor with the help of cement-sand screed;

- take into account the laying of pipes that will drain water.

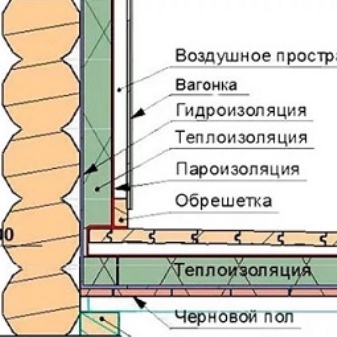

The roof

Of course, it is necessary to insulate and the upper plane of the bath. Especially relevant is such a requirement in the steam room and the washing room. The execution option depends on the type of roof. It is one thing if there is nothing on top. Another is when there is a cooled attic. And the third is if there is a full insulated attic on top. In the latter case, be sure to panel or roll insulation materials outside perimeter of the attic from the inside. Additionally, it is worth taking care of high-quality vapor barrier overlap. But if you choose a cold attic insulation of slopes is only an excessive expenditure of money. The ceiling is usually insulated by the deck method (with the laying of thick boards on top of the logs). An alternative - podshivnaya performance, when they are fixed to the floor joists from below.

In some cases, use the panel method of insulation, using multi-layered structures. Of natural materials for thermal protection of the roof, a mixture of clay and sand (straw, sawdust) is suitable. A more modern option - basalt or mineral wool. But from the foam plastic, as already mentioned, it is better to give up.

An excellent substitute for it will serve polystyrene and other plate heat insulation foam type.

It is recommended to insulate the ceiling on the steam room side. Metallized films are an optimal choice in this regard. In addition to keeping out moisture, they have another function - to reflect infrared rays. If you are using fibre insulation, you must take care about the drainage of moisture from the insulation layer. To this end, apply waterproofing membranes, passing steam in the direction of the attic (or the outer side of the slopes - in a variant with a warm attic). Floor insulation of the roof is practiced mainly in wooden baths of small area. Boards of great thickness are hammered into the log at 0.05-0.1 m. Their thickness should be at least 0.06 m (because it is also a load-bearing floor). From below, the boards are lined with vapor barrier and decorative coating. The upper edge of the boards should be insulated as much as possible.

Underlining insulation is acceptable in the bath of any area and from a variety of materials. The essence is simple - heat insulation saturates the gaps separating the beams, all this is placed on the rough ceiling. It is obligatory to cover with metallized film for more effective vapor insulation. The film itself is fastened with a stapler, and at the joints additionally made scotch tape. The wood is fully treated with antiseptic, and the wood veneer is additionally covered with a special heat-resistant varnish on a water basis.

Foundation

Speaking about the scheme of protection of the bath from heat leaks, often overlooked is the foundation. If it is not covered from external influences, the lower edge of the insulated floor will be damp all the time. And because of the emergence of ejection force, the building can warp. A complete warm foundation is created with polystyrene foam, mineral wool and bulk materials. When selecting the material, two key properties are taken into account: resistance to contact with the ground and the absence of water absorption.

Glass or mineral wool can only be used for external protection. It will be provided by a wall made of brick or board. It is better to refuse insulation with expanded clay. It, like other bulk insulation, is rapidly rotting and saturated with moisture.

You can use polystyrene - but because of the fragility of handling it is difficult.

About what kind of insulation to use in the steam room, see the following video.