All about heat exchangers for baths

Many people know the fact that without a proper supply of hot water, the steam room in the bath loses its inherent comfort and attractiveness. Even the simplest and most inexpensive heat exchanger, provided in the furnace, can provide boiling water for splashing the heater and washing in the shower. Let's learn more about heat exchangers.

Features

The lion's share of bath stove varieties is not notable for its fuel economy. This applies to all devices, including those that run on wood. Because of this, special requirements are imposed on the units:

- the steam room must be well heated in a short period of time, reaching sufficiently high temperature values;

- Bath stove should not take too much space;

- The presence of a sauna heater is mandatory;

- heater must work in intermittent mode.

Proceeding from all of the above requirements, the furnaces for the bath are designed and built so as to quickly reach the desired temperature settings and successfully maintain them over a long enough time interval. In this case A large mass of unused heat is simply released into the atmosphere through the chimney. Of course, it would be better to run this energy to heat water for washing or to heat adjacent areas.

One traditional and practical solution is to use the heat that is released during the burning of wood supplies. Today you can find on sale a lot of good models of stoves with a coil. If we talk about the heater without a water loop, you can equip it with a factory or homemade heat exchanger. This detail will be a great help in a more economical operation of the steam room.

Heat exchanger copes admirably with its main task, if the bath is installed furnace, which does not require a boiler for heating water.

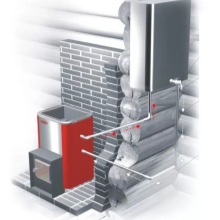

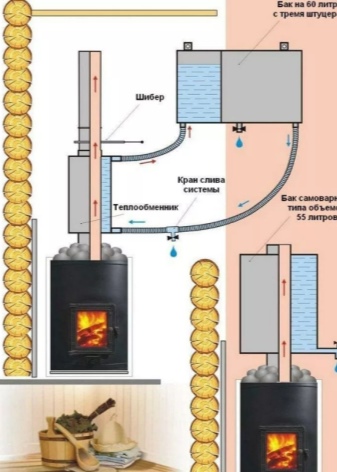

The heat exchanger itself is used to heat water in the bath. The principle of its operation is based on the physical properties of hot water, which expands and goes up, and the cold at this time remains at the bottom.

Most modern heat exchangers are compact in size, so the liquids in them are heated in a very short time. Two pipes are attached to this part at the top and bottom. So the hot water through the upper pipe, replaced by cold water below, is sent up to the tank.

The latter may be located not only in the steam room, but also in the adjacent space (most often it is a sink). In this case, the water of lower temperature, moving through the lower pipe, continuously and without additional feeds are added to the heating apparatus.

Bath stoves with heat exchangers are becoming more and more popular and in demand every year. These units are versatile and noticeably increase the comfort of taking bathing procedures. Furnaces equipped with quality heat exchangers have several significant advantages that attract customers:

- they are characterized by a long and trouble-free service life;

- They are also attractive because of the compactness of the heaters;

- high efficiency and speed of heating the sauna room;

- the possibility of independent manufacture of the device.

Overview of types

Heat exchangers come in different types. Each type has its own characteristics of operation and device. Let's get acquainted with them.

Tubular

Heat exchangers of this type are among the most common and popular. They are usually made of 2 practical materials:

- Of copper pipe;

- Of steel pipe.

Tubular heat exchangers are made in the form of a circular or flat "snake". Such systems can boast of high indicators of water heating, which speaks of their efficiency and productivity of work. In addition, tubular heat exchangers are attractive simple method of manufacture, as well as installation on the sauna stove.

Tubular exchangers do not have a large number of disadvantages, but we should not forget that they are very sensitive to overheating. This nuance must be taken into account when using a sauna stove with such a detail.

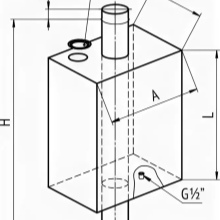

Boxed .

The second most popular variety of heat exchangers. They are produced from heat-resistant steel in sheets. Parts are made in the form of compact containers of disc type or cistern of rectangular shape. If we consider this part as a whole, it is an ordinary container made of heat-resistant material.

To this element is welded sockets for further connection, supply and withdrawal of liquid.

Framed

Frame subspecies heat exchangers are a sophisticated design consisting of practical steel tubes. The latter are welded together to form a set of a certain number of registers. In terms of construction, this subspecies replicates the structure of the steam boiler. For this reason, the construction itself is as reliable, strong and sturdy as possible. It is capable of withstanding prolonged overheating and high steam pressure without negative consequences.

Batch

These varieties of heat exchangers are made for bath stoves only by specialized enterprises. Homemade or homemade batch parts, as a rule, do not occur. These are highly efficient devices. However, they are prone to burn through the walls, even if there is not the greatest overheating.

With different arrangement of water tanks

Heat exchangers are also divided by the location of the tank for the heated liquid.

- In the steam room. If this arrangement is provided, the length of water pipes decreases, and this has a beneficial effect on the rate of water heating. But there is one important minus in such a decision for many baths - so the rooms of small square footage seem even more cramped and overloaded.

- In the shower room. Not a bad solution. Many experts believe that this arrangement of parts is optimal. But it also has a serious disadvantage - the length of the pipeline necessarily increases.

These options share one common problem - weak and not the highest water head. The fact that the height of the bath is rarely more than 2 meters. If you subtract from this value the height of the liquid tank (about 50 cm), the greatest height of the water intake pipe drops to 1.5 m. It means that a stationary shower will not work and you will have to wash only with a flexible hose, without raising it to too great a height. This problem is solved by taking the tank for heated water in the attic of the building - this is the third type, depending on the location of the tank.

And in the latter case, there can be problems of their own. Inevitably grows the length of the pipeline, heat loss increases, the tank has to be additionally insulated. There is a risk of having problems with water refilling in the tank.

By location

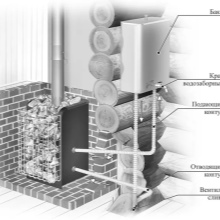

Heat exchangers are also divided by the place of their own location in the furnaces. There are only 2 options for locating these parts:

- In the stoves themselves;

- near the chimney.

The first option (i.e. the built-in internal heat exchanger) allows you to heat water at a relative speed, but in this case there is a risk of boiling. If the heat exchanger is located near the chimney, the water in it will not be able to boil, but the heating process itself in these circumstances is noticeably delayed.

How to choose?

Today the range of bath stoves is huge. On sale you can find cast iron, iron or brick units with closed or open heater. To choose such equipment for the bath is not difficult. But the choice of a particular heat exchanger often turns out to be a more difficult task.

If you want to buy a quality heat exchanger for a wood-burning sauna stove, you must first decide what kind of system will suit you best.

- Built-in coil. This is one of the simplest options, made in the form of a spiral tube. However, many users believe that variants of the samovar type (for example, natrubnye) are more optimal for use in the bath.

- 2 capacities - lower and upper.

It is important to calculate in advance the area of the bath premises, selecting the optimal heat exchangers. If it is planned to install this element in the steam room and only to obtain hot water, you can choose not the most powerful design.

If the heat exchanger is planned to take outdoors, but it will be used for heating the premises, it should provide at least 5 kW per square meter of available space. When the part in question is not needed for heating, but for water flow, the volume may be different.

When choosing a heat exchanger, you should also pay attention to its dimensions. It must not cool the stones, so its dimensions must be such that all the heat is not taken away from the stones. The exchanger must warm up along with the stones.

Installation

If the heat exchanger is delivered with the chosen stove, the installation is quick and easy. You will only need to read the installation instructions very carefully and correctly assemble all the necessary components. The user will only have to connect the equipment directly to the system, relying on the correct schemes of action.

If all the components go separately from each other, here it is necessary to act differently. First, the owner must familiarize himself with several important rules, which must be adhered to.

- The heat exchanger should consume no more than 10% of the total energy (which the furnace produces). Only in this case the unit will show high efficiency values.

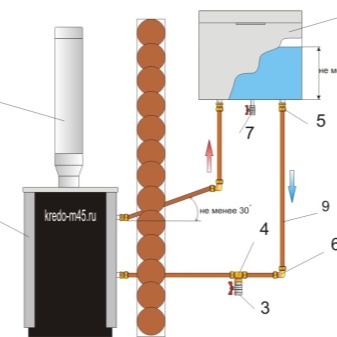

- Pipes must be exposed so that the water flows by gravity (at an angle of 250 degrees), in a direct flow. Movement in the opposite direction should be carried out under the condition of a 30-degree angle.

- The foreman should allow for a reserve of power to cool down after the fuel has burned through.

- Each model requires the necessary water reserve. If there is not enough liquid, it will start to boil very soon. Because of this, deposits appear on the walls and a fire-hazardous situation can occur.

Now let's look at how to properly connect the heat exchanger to the sauna stove, if the tank is located in the steam room.

- Inlet to the hot water tank should be at least 5 cm higher compared to the upper connection of the register. This condition must be observed to ensure better circulation.

- The register located on top should be at a distance of 1.4-1.5 m from the floor surface. This is under the condition that the floor under the stove is up to 15 cm. The bottom of the tank in the steam room should not be lower than 1.5 m (higher is better).

- If the height of the tank is only 0.5 m, then the total installation is 2 m. There is another half meter to the ceiling. If there is a water supply, then there will be no problems with the flow of water.

There is another scheme of installation.

- The tank should be installed lower. Connector for the circuit of the supply type is set at the side.

- If the water level will be higher than the top connector, then the circulation will not be achieved. In the heat exchanger itself, the water will stand and occasionally boil, remaining cool in the cistern.

Installation and connection of heat exchangers is not the most difficult task. The main thing is to calculate everything in advance and choose the appropriate components. If you yourself are afraid to carry out such work, it is better to turn to professionals, who for a fee will do everything for you.

Tips for use

Let's break down some useful tips on the operation of heat exchangers in the bath.

- Owners should always make sure that all fasteners are firm, immovable. This is the only way to minimize the possible deformation of the recuperator components under the influence of high temperature values.

- All components must be perfectly matched to the main unit.

- It is very important that the safety rules are observed. Pipes must never be attached in the immediate vicinity of walls - this can lead to unfortunate consequences.

- It is necessary to always ensure that there is enough water in the tank. If this is not done, soon the user will be faced with the formed scale, and in the worst case - with a fire hazard.

- Owners should constantly check whether the equipment installed in the bath is working properly. If only you notice that the equipment is functioning improperly and turned out to be faulty, it is necessary to immediately sound the alarm. It is dangerous to leave such defects for "later".

- Only heat-resistant gaskets should be used. You should regularly check the condition of the gaskets.

- If you have finished all the bathing procedures and are about to leave the sauna, you must drain all the water from the existing system.

- It is not allowed to start heating until the owner is sure that the storage tank is full of water.

- If your bath has a good quality brick stove with an internal water circuit, and it is flooded, and you forgot to pour water in time, you should not do it while the unit is warmed up.

- It is strongly not recommended to install a heat exchanger directly under the heater unit, as it will simply take away all the heat, not allowing the stones to warm up to the desired temperature. Because of this, you will not be able to give steam, and the whole point of the bath will be lost.

On how to choose a heat exchanger, see below.