All about thermal insulation of the bath outside

Insulate the walls of the bath both inside and outside. Reliable sealing helps to reduce the consumption of heating material, maintain a good microclimate in the steam room. A properly assembled sauna should heat up quickly and cool down for a long time. How to competently organize the external thermal insulation, and whether it is needed at all, we will tell in our article.

When is thermal insulation necessary?

Two conditions are important for the traditional Russian bath - high temperature (+ 80-90 degrees) and very high humidity (70%).

One heating alone does not keep the desired climate regime in the steam room, it is important not to lose the precious heat through the cracks and thin ceilings.

With poor insulation the floor and ceilings cool in winter, gaps in the walls contribute to drafts. Lack of insulation leads to the following negative factors.

- More heating resources are required, which means heating costs increase.

- Working at full capacity causes the equipment to wear out faster.

- Despite all efforts, the bathhouse heats up slowly and has difficulty retaining heat through constant heating.

- The building itself of an uninsulated sauna undergoes gradual deterioration. Winter frost and high humidity from the inside contributes to this. Water getting into microcracks and joints freezes, expands and negatively affects the integrity of the building.

- If the structure is made of wood, moisture seeping out of the steam room will lead to swelling, warping, rotting and fungus infestation of supporting walls.

- The lack of external insulation contributes to water accumulation between the walls and the internal insulation.

Let's analyze in which cases you can do without external insulation, and in what cases not. Insulate the walls is necessary if the bath is combined with a house or is a guest house, then maintain a comfortable temperature must be daily.

Bathhouses visited every 1-3 days, or where people take a steam bath several times a day, also need external and internal insulation.

But if people do not live in the neighborhood, but only visit it occasionally (when they come to the cottage), no matter how insulated the walls are, without constant heating they will freeze thoroughly. In such cases, there is no sense to engage in external insulation. For one-time bathing procedures, internal insulation is also sufficient.

Materials

To the thermal insulation material selected for the external walls of the baths, special conditions are imposed. It should not only protect the structure from the cold and wind, but also do not allow moisture coming from inside to stay in the walls and destroy them. To do this, the vapor must be able to pass through the walls and escape into the atmosphere. Such properties are characterized by materials with a high vapor permeability coefficient. To cope with the problem of hot vapors, the inner insulation layer should consist of a vapor barrier membrane, and the outer layer should have good vapor permeability properties.

Let's consider insulators, in varying degrees of effectiveness suitable for the external protection of baths made of gypsum blocks, bricks and other building materials. They do not have the same technical characteristics, so everyone must decide for himself which insulation he considers more acceptable to protect your building.

Styrofoam

Insulator is endowed with many advantages, but, like any construction material, it also contains disadvantages. Let's start with the pros:

- Does not let heat out of the building;

- does not allow moisture to pass through;

- has a good vapor permeability;

- strong and durable, can serve up to half a century;

- well insulates sound.

The disadvantages include the following points:

- the material is fire hazardous, requires coating with a special solution;

- it can live rodents;

- has a high cost, much higher than that of Styrofoam.

Styrofoam

In terms of technical properties, similar to Styrofoam, but it also has differences. The positive points include:

- moisture resistance;

- ease;

- ease of installation;

- low cost.

On the negative characteristics should also be noted:

- in terms of strength and durability it is significantly inferior to polystyrene foam;

- has low environmental safety indicators;

- inflammable;

- when installing will need glue, putty and certain efforts;

- poorly vapor permeable, which means that the external walls can accumulate condensation.

Basalt mineral wool

The material is a kind of mineral wool, but endowed with improved technical characteristics. Basalt boards have significantly more advantages than disadvantages. Their advantages are as follows:

- fire-resistant material;

- Good at retaining noise and heat;

- service life reaches 50 years;

- does not rot;

- does not attract rodents and insects;

- is endowed with good water repellent properties, the material passes, but does not retain water.

There are only a few disadvantages:

- a large number of joints at the joints;

- the high cost of the product.

Other types of mineral wool can also be used to insulate the bath - stone wool, slag wool and glass wool. Their performance is slightly lower than basalt boards, but the cost is more loyal.

Foamplex

The material has a finer porous structure than foam plastic, so it surpasses it in density. Foam foam is endowed with many advantages:

- It is strong, reliable and durable, and serves up to 45-50 years;

- The light weight of the material does not allow overloading the walls;

- moisture-proof;

- environmentally safe, in combustion does not emit toxic substances;

- well keeps heat, does not let it out of the building;

- easy to handle and install.

The disadvantages include:

- poor vapor permeability, which can be the cause of short-lived walls of the bath;

- the material is able to melt and ignite (class GZ), although it does not emit poisons in combustion;

- does not protect against rodents.

Ekovata

The material is also called cellulose insulation, it has a loose fibrous structure. Endowed with many positive characteristics:

- is valued for its high environmental performance;

- has low water permeability;

- the insulation has no seams; it fills all the voids;

- absorbs noises well;

- Has an affordable price.

Disadvantages of ecowool also have:

- it is not possible to install with your own hands, as special equipment is required to fill all the gaps with wool;

- if the material is laid in a wet way, it will take time to dry out completely;

- because of the weak rigidity of ecowool will have to build a frame for installation;

- the material gives a long shrinkage;

- ecowool does not burn, but smolders for a long time, which can lead to the ignition of other materials.

Step-by-step instructions for insulating the sauna

Even at the stage of construction, produce insulation of the ceiling, even if the bath is built with a loft. It is also important to insulate the foundation. External insulation of walls is made in two ways: "wet facade" and "ventilated facade".

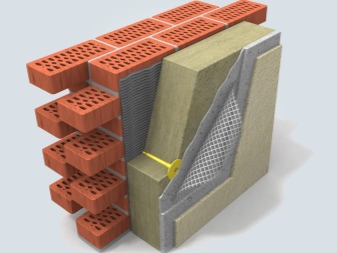

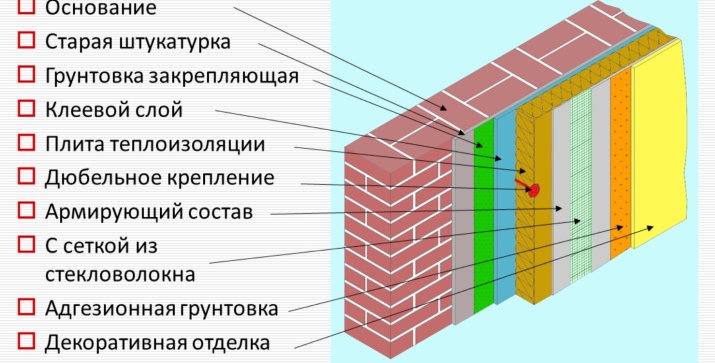

Wet Facade Technology

You can use polystyrene foam or mineral wool as a heater. The first option is more convenient, it is durable, easy to install, has good moisture resistance. Further actions are performed in this sequence.

- On the surface of the walls, a primer layer is applied.

- With the help of the level, the facades are performed, the walls should be perfectly even.

- Even before gluing, it is necessary to make a scheme of installation of the boards.

- Adhesive is applied to the sheet along the perimeter. The thermal insulation boards are mounted to the facade walls with adhesive. The work should be carried out strictly according to the scheme.

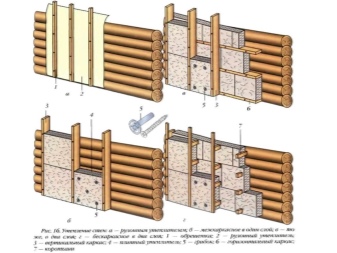

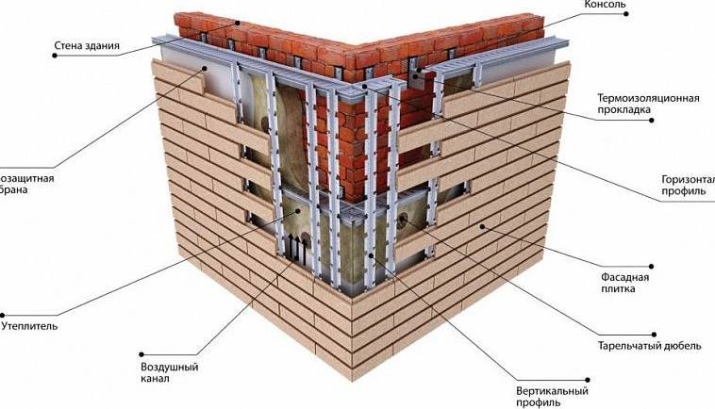

Technology "ventilated facade".

This is a more expensive and complex technology, since the cost of the frame is taken into account. Perform the work as follows.

- On the walls set up mesh crate on the size of the insulation boards. If you do the sections to a centimeter less, the material will sit tighter and will be held on the wall itself.

- The joints can be glued with construction adhesive tape, this will give the surface tightness.

- On top you can lay isospan.

- The last layer is the finishing of the walls. For it, a wooden frame is installed (on top of the insulation), on which the decorative finishing material is mounted.

Brick

Brick buildings need external insulation, especially in regions with a cold climate. Walls heated to +80 degrees from the inside are subjected to freezing to -30 degrees from the outside. Such a shock temperature regime is difficult to withstand for unprotected walls. Moreover, bricks are endowed with an excellent thermal conductivity, and if you do not insulate the surface, it will be heated in the street, not the bath.

Brick walls are insulated with foamlex, mineral wool, in principle, any of the above-mentioned insulation will do.

The masonry technique is more often preferred "wet facade", it is cheaper. But if you have money for the crate, you can also use the "ventilated facade".

"Pie" in this case will consist of a frame, insulation boards, vapor barrier and ventilation protection (preferably roll), finishing. Do not forget about the ventilation gaps. Trim is performed from a metal profile or bar, distributing it evenly in all directions. The final paneling can be anything - wood, metal siding.

Aerated concrete

Insulation of aerated concrete walls is no different from brick walls. You can cover the surface with foam blocks, basalt plates or polystyrene foam, a thickness of 130-150 mm. As the final paneling is often used decorative brick.

From cinder blocks

Baths made of cinder blocks or expanded clay concrete blocks are insulated in the same way as brick structures. A frame with cells to the size of the selected type of insulation is made. Mounted plates.

The top is covered with the foil and the counter battens are installed, providing the ventilation gaps of not less than 15-20 mm.

The last layer is the finishing. For it you can use a block house, imitating logs, or clapboard.

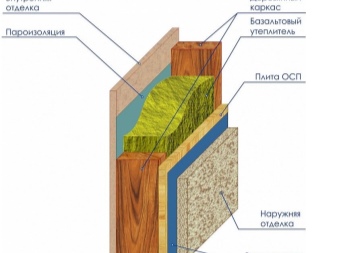

Frame

Frame baths are immediately built with insulation inside, this is their peculiarity. Therefore, external insulation for buildings of this type is rarely used. Over time, when the internal insulation begins to require replacement, the outer walls are insulated.

For a frame bath it is enough to lay a ventilated layer. Prepare the walls: caulk the cracks, clean up. A special membrane is used as a vapor barrier. Facades of the new bath can be covered with decorative material.

Wooden

Wooden baths are insulated from the inside, and outside only caulk the cracks that can give a draught going between the logs or timber. The technology of "ventilated facades" is used only when the wood material is too thin and needs to thicken the walls. Thermal insulation is chosen that allows steam and moisture outward, not retained in the wall. For example, foam is not suitable for such purposes, but blocks of mineral wool.

Recommendations

For those who have decided themselves to insulate the facade of the bath, we offer a few tips that will help in the work.

- If the log cabin still needs to be insulated externally, it is enough to install a vapor barrier batten under the cladding, without the insulation itself.

- For laying polystyrene foam is better to use the technology of "wet facade".

- EPPS boards as insulation for the bath should not be used, the lack of water vapor permeability will lead to condensation on the walls.

Whatever you choose as insulation for exterior walls, you should remember that success can be achieved only by comprehensive methods, insulating the floor, ceiling, doors and windows.

How to insulate a bathhouse, see below.