All about building a 3x4 bathhouse

To date, the bath is considered the most popular place for recreation, as in it you can not only take a good bath with a broom, strengthen immunity, improve the condition of the skin, but also have fun in a circle of friends. That is why most owners of country plots decide to build such structures. If the dacha area is small, then experts recommend choosing projects of baths 3x4 - they are inexpensive, take up little space and are installed in a few months.

Choosing Materials

Currently there is a huge choice of building materials, of which it is possible to erect a bath of size 3x4, with a special demand for projects of wooden (glued beam, log), frame and stone (aerated concrete, ceramic blocks, concrete, brick) constructions.

The timber baths are considered the most budget and environmentally friendly, heat procedures in steam rooms built of timber allow to strengthen immunity, have a beneficial effect on the skin and lung system. For the construction of such baths are used planed beam standard length of 6 m.

If it is planned to erect walls with a width of 3 m, the material is sawn in half.

Proven themselves and frame-shaped structures, they are considered the lightest in weight, so the installation does not require preparation of a massive foundation. The walls of such rooms are erected from timber and board panels, between which is placed the heat insulation. Inside the premises is usually finished with wooden battens, while outside - with siding or block-house. Such steam rooms are inexpensive to operate, they quickly warm up and retain heat, which saves on fuel. The disadvantage of frame-shield baths is that for their hydro, steam and heat insulation uses synthetic materials, which prevent natural air exchange in the rooms.

A 3x4 bathhouse can also be built from ceramic blocks and foam blocks. This material is considered the most convenient in construction, it is characterized by high strength, resistance to moisture, temperature differences and excellent heat retention, without shrinkage. Foam blocks are used to build load-bearing walls, as partitions are usually used lighter gas blocks. Construction of blocks must be insulated outside and inside install the moisture and vapor barrier. In addition, these rooms require additional plastering and decorative finishing. The disadvantage of such buildings - low environmental friendliness and air exchange

Many masters for the construction of baths choose bricks, which have high performance characteristics and are easy to lay. Despite the fact that the price of brick is much higher than the cost of wood, its service life is much longer and can be 120 years. In order for a brick steam room to warm up quickly and retain heat, its walls are insulated both outside and inside. Decorative trim is usually made of clapboard.

In addition to the main building material, the construction of a 3 x 4 m steam room also requires vapor, water and heat insulation. This can be glass wool, mineral wool or foam.

The estimate should also include fittings, doors, windows, as well as sheet metal, lighting fixtures, installation foam, antiseptic and roofing materials.

Planning the design

Mini-bathroom size 3x4 refers to the outbuildings, the construction of which is regulated by approved government standards SNIP 30-02-97. Therefore, before starting the construction of such a structure should know all the sanitary regulations, to choose a suitable area on the plot and prepare a draft. Under the construction is recommended to choose a flat area, where the groundwater is deep. In addition, it is worth taking into account that the future bath must blend in with the overall view of the territory and combine with other buildings.

Making a project steam room 3 by 4 meters, you need to take into account all aspects - this will allow you to organize the construction work properly, without disrupting the timing. To begin with, you should use special programs to create a sketch of the construction, you can also draw a drawing on the checkered sheets, observing the scale. The project should include a top, side, front and sectional views. On all projections necessarily indicate the location of ceilings, furnace, doors, windows, rafter system, walls and foundations.

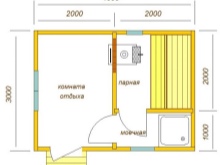

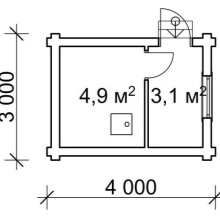

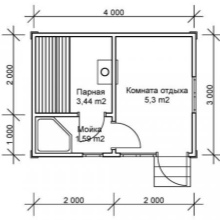

Bathroom 3x4 is considered a small structure, so it is usually planned for three main rooms: rest room, washing room and steam room. If you plan to use the steam room all year round, then it will not hurt to provide in the draft and a small anteroom. It will protect the room from cold air in winter. To increase the space, you can build a two-story sauna. In this case, the first floor will house the washing room, steam room and pre-bath, and the upper floor - the rest room.

Step by step instructions

For the bath to reliably serve for a long time, during its construction, you should perform all the work in a strict sequence. If it is planned to build a steam room 3 by 4 meters with their own hands, it is recommended to choose projects with frame structures. Such construction is uncomplicated, carried out quickly and inexpensive.

Before you start erecting a building, you should make a draft, prepare a drawing, get permission to build an object, make a calculation of construction materials and prepare the territory. Also, special attention should be paid to the arrangement of a drainage pit and the organization of the foundation, and then you can begin assembling the building, installing the rafter system.

Once everything is done, we make the roof and do finishing work.

Site preparation

Frame construction should be installed on a perfectly flat surface, so the allocated territory for construction is carefully leveled, cleared of plantings. The most difficult work in preparing the site is the uprooting of stumps. To do this, they are first burned, then holes are drilled inside and filled with resin or covered with salt, saltpeter (thanks to these substances, the wood will quickly decompose). Areas that have pits (places of constant accumulation of water) are filled. Plots with too wet soil require the diversion of moisture - for this it is necessary to additionally prepare drainage ditches, giving them the right direction and slope.

Foundation

Since a frame construction with an area of 12 m2 has a small weight (from 2 to 3 tons), its foundation can be built according to a simplified scheme. The most common choice for such baths is columnar foundation - it is installed on asbestos-cement pipes, which are poured with concrete.

It is also possible to build a small structure on a monolithic foundation, which is prepared as follows.

- First of all, a rectangular excavation is dug on the site. Its depth should not exceed 40 cm, width - 3.5 m, length - 4.5 m.

- The next step in the preparation of the foundation is to create a formwork, which should be 20-30 cm above the ground. The bottom of the pit is covered with a cushion consisting of gravel and sand.

- Then the organization of drainage and everything is poured with concrete, which is prepared from cement of grade M250 or M200. Such a foundation should stand for 2 to 4 weeks.

Often frame structures are also installed on a strip foundation. To do this, a trench 35 cm deep and up to 40 cm wide is dug, it should repeat the perimeter of the future building. Then a formwork is prepared from boards or plywood with a wall height of 20-30 cm and equipped with a pipe outlet or drainage. The formwork space is poured with a mixture prepared from water, sand and cement. To get a strong foundation, it is recommended to use additional reinforcement - it is placed in the formwork, covered with stones, brick rubble and poured with concrete. The strip foundation dries for about 3 weeks, after which you can continue the construction of the steam room.

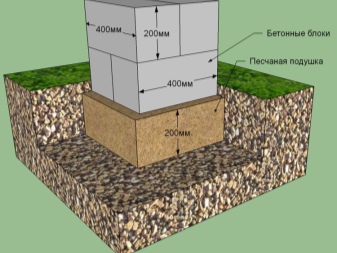

The frame type bathhouses can also be erected on a block foundation, for which a site is prepared and a pit is dug for concrete blocks.

The bottom of the hole is filled with a cushion of gravel and sand up to 15 cm high, then everything is compacted with soil and the block pillars are installed.

Erecting the Frame

The initial stage in the construction of a frame bath is its strapping board 100 * 50 mm, which should be prepared in advance (treated with antiseptic agents). First of all, the walls are marked, then you can begin lining the outer contours.

The upper and lower strapping is made of boards, they are fixed with nails, while the strapping of the basement is fixed with special supports. The frame must be erected by controlling the horizontal level, and if there are deviations, the multi-layered pads are laid of roofing felt. Pillars should be installed taking into account the installation of thermal insulation and further cladding. To make the frame turned out to be strong, the strapping and joists should be fixed between each other with metal plates, and upon completion of the work, it is recommended to treat the strapping with a protective mortar that prevents deformation and rotting.

Start assembling the frame is best done with the formation of the corner. To do this, first of all the wall is assembled, which will later connect to the strapping. Then you need to check everything for verticality and proceed to fix the temporary struts. The assembly is completed by installing the frames, which should be at right angles. After the frame is installed, work begins on the interior and exterior cladding of the building.

Exterior and Interior Decoration

The outside of the sauna can be decorated with plaster, decorative tiles, as well as siding or block house. Before the external cladding, thermal and waterproofing material is put on the walls. As for the inner lining of the premises, it is often performed cladding, which can not be covered with paints or varnishes, as when heated they will emit harmful vapors.

Before you finish the interior of the need to install the doors and windows, all the joints seal with acrylic sealant. Vapor barrier in the steam room is made only of foil, in the washing room and rest room it can be done with parchment.

To be convenient to use the bath, the height of ceilings in it should be at least 2.2 m. This is important to consider when installing insulation material and decorative finishes.

The joints between the ceiling and the walls should also be well insulated and sealed with sealant. It is best to cover the walls with lime veneer, as it has a pleasant smell and high performance.

The furnace is installed in the steam room according to all fire safety rules. The back wall, where it is planned to be placed, must be lined with metal sheeting. In the future, the walls can be decorated with decorative items.

See the following video for an overview of a 3x4 bathhouse.