All about panel baths

Knowing everything about panel baths is very important for any builder interested in the arrangement of a country, suburban or urban land plot. It is especially important to understand the pros and cons of prefabricated paneled baths, to imagine how to make a frame and paneled bath-house. Another nuance to consider is the peculiarities of projects of 6x4 baths and other sizes of buildings.

Pros and cons

The most important positive feature of a panel bath is its attractive appearance. In any case, it is the one they talk about most often. But also frame-shielded and prefabricated-shielded construction:

-

Will give only minor shrinkage;

-

Will not require significant expenditures;

-

is erected in a short period of time;

-

allows you to avoid hiring professional builders;

-

warms up quickly (especially if modern class heaters are used)

-

compatible with a variety of types of finishing inside and outside;

-

it is used for quite a long time.

The difference between the frame-and-board and prefabricated buildings is mainly in the fact that the latter are assembled from prefabricated elements manufactured at the factory. The first type requires a lot of effort directly at the construction site.

It should be noted, however, that the frame-shield construction is not monolithic enough. Shields will leak air and heat through the gaps at the joints. This can only be solved by enhanced thermal insulation according to all the rules; however, it should be noted that the pluses still outweigh.

Projects

Making a project, you need to think as carefully as possible about the individual details. The more subtleties are reflected already in the original documents, the more convenient it will be to use the bath later. The main nuance - the location of its isolated or near another structure (most often a residential house). Additionally take into account the placement of utilities. In the absence or lack of such, make a separate project for the pulling of utilities.

Also need to find out the characteristics of the soil at a particular site. Important: "to consult with neighbors" or dig a hole on their own is almost meaningless. Only professional extraction of samples and their further analysis in the laboratory will provide accurate answers to all significant questions for construction. When these answers are received, it remains to summarize your own requirements - and the desired description of the bathhouse is ready. On this basis, you can already make sensible drawings.

The minimum allowable area of a panel bath is 3x4 m. But ideally, you should focus on the size of 5x5 m. This is already enough to comfortably accommodate all the necessary rooms in a one-story building - and at the same time will not be taken away too much space on the plot. The layout is best selected individually. Preparing or choosing a project, you will also have to consider the optimal pace of work for yourself.

The placement of the rooms inside is determined by the desired number of pieces of furniture and their size, not vice versa. For example, it is critical to consider the length of the bench. In the room for leisure should include the use of a sofa, a table and chairs.

A big role is also played by thinking about the optimal location of the anteroom. It is placed so that when the door is open outside air does not penetrate inside (or penetrated to the smallest extent).

When designing the washing room, take into account where the water tank will be placed. Brooms can also be dried in the attic, but then it must be insulated. Comfortable leisure provides the creation of verandas or terraces. Important: Since the construction used many wooden elements, you must provide maximum fire protection measures at the design stage. You also need to take into account the increased protection of walls against moisture.

A typical set of rooms includes a vestibule (aka anteroom), a sink, a steam room. Room for leisure can be equipped separately, but if there is not enough space, this function is performed by the pre-bath. One possible drawing of the panel bath has a size of 3x4 meters.

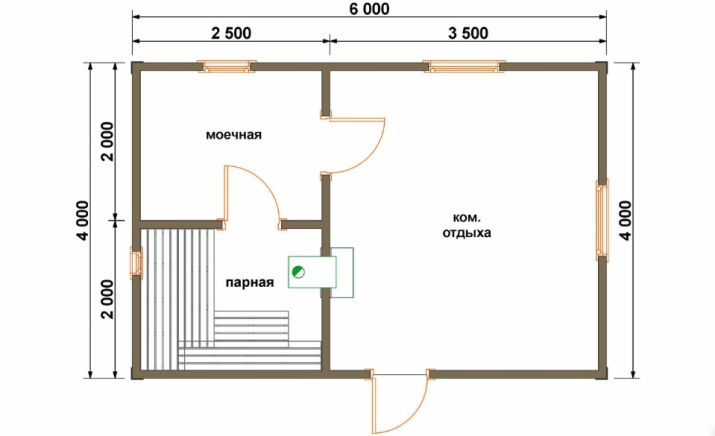

The sink is 1.59 m² and the steam room 3.44 m². If you choose a 6x4 m project, you can go for another option (with a 3.5x4 m rest room).

How to build?

Before you make a sauna of panels, it is necessary to carefully choose a suitable type of basic structures. Oriented strand boards are widely used. It is a dense and strong construction. It practically does not peel off and is not affected by temperature fluctuations. Cement-bonded particleboard is stronger than the previous option, more resistant to moisture, but it is heavier.

Chipboard can also be used. They are environmentally friendly and lightweight, protected against mold. Chipboard is not bad vapor permeable. Sometimes use and plywood special category, passed a special treatment. It consists of many layers, it is vulnerable to little destruction under bending and compression, resistant to moisture ingress.

Separately, it is worth deciding whether to make a sauna-house or to separate these rooms. In general, such a construction may have certain advantages, but they are outweighed by one huge disadvantage - an increased level of fire danger. In addition, it is extremely difficult to comply with basic health standards when combining buildings. The way out is the construction of a bath-house in a different way (with a small living area in the attic). Anyway, to choose the best option for yourself - already half of the success.

Preparing .

First of all begin, of course, to make the base. Under the panel bath most often lay pile (pole) foundations. To make them, you can use asbestos-cement pipes of a section of 0.2 m. Under them, excavations are dug to a depth of 1.5 m (the width should be slightly greater than the structure itself). In the lower part of the excavations concrete is poured after the installation of pipes, and then suspend all work until the stone has reached full normal strength.

Erection of

When the foundation is ready, carry out its waterproofing. Most often for this purpose, a roofing felt is used, secured with a coniferous bar with a diameter of 0.2 m. Strapping is carried out as follows:

-

lay out the prepared bars;

-

attach them to each other;

-

level everything on the perimeter;

-

If necessary, repair defects with concrete or roofing felt;

-

Place vertical supports in the corners and in the places where the partitions are placed;

-

Make the upper strapping in the same way as underneath.

Over the bottom dressing fasten beams. On them mount the floor boards. Insulation against water ingress and heat leakage is made only after the walls and the roof are finished. Most often used machine oil is used to treat the timber. This is a reliable protection against rot and pest infestation.

Openings for windows and doors in solid boards can be cut with a chainsaw. But it is better to order the product immediately with made in-house passages. Assembling the roof after the completion of work on the wall joists includes:

-

laying the ceiling beams (usually with a pitch of 0.6 m);

-

forming the rafters (it is best to assemble them on the ground);

-

fixing the spans on the roof (with the rafters resting on the overhanging sections of the rafters);

-

Binding of rafters by means of purlins;

-

fastening the vapour barrier and counter-battens;

-

Covering the frame with finishing face material.

The roof of the panel baths is erected relatively easily. All that is required from the builders - to correctly determine the load. Often use gabled, heavily sloped solutions. It is better to avoid heavy materials altogether. Otherwise, simple versions of the foundation may not be able to withstand the load created.

Wall processing

Even before the assembly of the panel construction, it is already possible to treat the blocks with special protective agents. In this case, installation is postponed until the impregnations are completely dry. Often, the manufacturer's instructions indicate that additional treatment of the panels (other than factory) is not required. But in any doubt, as well as the use of known untreated wood will have to use flame retardants and moisture protection.

Insulation

Special insulation is required for any bath in the middle zone and in the more northern regions. It is not recommended to use mineral wool - it degrades from contact with water. Much better performs itself foam polystyrene. Made of it the panel is mounted inside the frame and outside overlap waterproofing. Other options for thermal insulation is not even worth seriously considering.

Finishing

When decorating the paneled bath inside, it is logical to apply wooden linings. Most often, aspen, alder and lime are used for this purpose. Such wood is suitable even for the steam rooms. Installation of battens implies its pre-treatment with compounds that inhibit decay. After that it is necessary to:

-

fix the vapor barrier;

-

Make a grate of joists;

-

fill in the vacant areas with insulation;

-

install the waterproofing;

-

Stitch the batten itself.

Exterior finish is most often made with siding or block house. Siding can be taken as a metal or made of plastic. The first option is more durable and reliable, but the second is cheaper. An alternative route - the use of cement-sand plaster.

The overall conclusion is simple: the construction of a panel bath will not take much time and is quite accessible even to non-professionals.

Ready-made examples

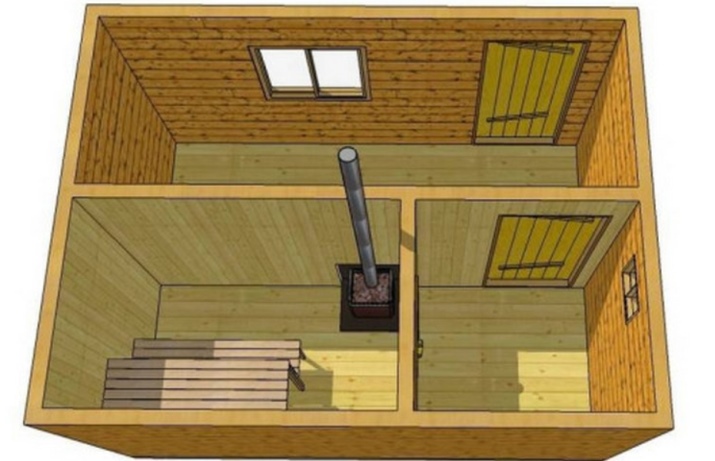

The photo shows a typical scheme of the arrangement of a panel bath from the inside. In one corner of the steam room is placed a stove, and in the other - a stepped shelf. The washing room is equipped with a separate window.

And this is what the finished sauna looks like from the outside. It is divided into three rooms and is complemented by a thoughtful terrace.

The following video tells about the advantages of a frame bath.