All about sandwich pipes for baths

Assembly of the chimney for the bath is a very responsible job. Nevertheless, it can be done by yourself, using a sandwich pipe. It is quite easy to install and very durable. What is good about such a chimney, from what metal it is made, what models exist - we will try to answer these and many other questions in our article.

Features

Sandwich pipe for the bath is a pipe in a pipe, the distance between them is filled with heat-resistant material with high insulating properties. Several factors are peculiarities.

- Quality pipe is made of stainless steel. The inner part should have a thickness of 10 to 12 millimeters.

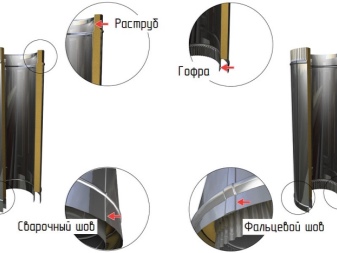

- Since the design is performed by welding, respectively, welds qualitatively weld and check whether there are no uncooked areas, caverns or overlap, which can be seen with the naked eye. Then the seams should be grinded with a grinder.

- Used insulation material, which is most often mineral basalt wool, according to the standards should be a thickness of 38 to 54 millimeters or more, the density of 115 to 130 kg per cubic meter.

- Individual sectors of the chimney are shaped socket, in which not only fasteners are used for mounting, but also high-temperature sealant, which is also used to blot the joints of the device.

- The device can be equipped with revision windows, through which the channel is inspected and cleaned at least once every six months.

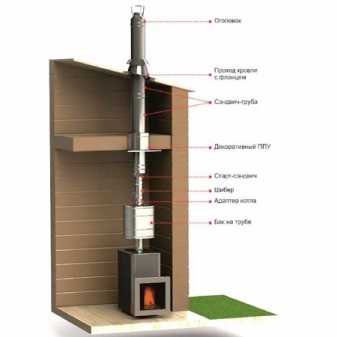

Structurally, the chimney is made as a collapsible constructor. It contains:

- straight elbows with a length of 95 or 45 centimeters;

- metal clamps of different diameters;

- Hatch, which, except for its function, also serves as a spark arrestor;

- Various connecting fittings;

- apron to protect the passage gate from atmospheric precipitation;

- mandatory installation of bushings.

What are they?

The design of a standard sandwich pipe on the furnace contains 3 main elements:

- outer jacket (pipe) - made of various materials such as stainless steel, copper, galvanized steel, ceramic or fire-resistant glass;

- inner tube - similar to the outer tube, but smaller in size;

- insulation material - located between the pipes, it can be rock wool, basalt board or other material for insulation.

Let's take a closer look at the main types of devices, as they affect the price and service life of the sandwich pipe chimney.

Steel

Almost always made of stainless alloy steel, which has great resistance to corrosion. Such pipes can be easily bent in the right direction, they have a low weight. They can be equipped with cleaning hatches and grids to extinguish sparks. Chimney material consisting of galvanized steel is cheaper than stainless steel.

At the same time, galvanized is less anti-corrosive - a small damage to the outer layer is enough to cause rust. Some stove builders use combined stainless steel and galvanized chimneys in the chimney: a stainless steel pipe is placed in the steam room, and galvanized pipe is installed in the attic and outside, along the wall.

But this approach has a significant disadvantage in the form of complexity of connection of different materials.

Ceramic

Pipes made of ceramic have many advantages:

- resistance to high temperatures;

- Not harmful to the environment, since they are made of clay - an ecological natural material;

- Small weight in comparison with a chimney from concrete or brick;

- convenient use;

- availability of cleaning doors.

Structurally, the devices look like small modules of about 30 centimeters in height, containing 3 layers. The smoothness of the inner surface prevents the accumulation of soot, at the same time providing an excellent draft of air.

Glass

The pipe is made of modern fireproof glass - when broken it forms shards without sharp edges that are impossible to cut. It looks very attractive, the material is resistant to temperature fluctuations. The service life is high, cleaning is easy.

The main disadvantage is the high price. However, over time, the situation may change.

How to choose?

Most often choose devices made of stainless steel, so it is necessary to pay attention to the quality of the inner pipe material, taking into account that when heated, the temperature in the chimney is from 800 to 1000 degrees Celsius. The inner diameter of the chimney should not be less than 10 cm. That is why experts advise using pipes made of stainless steel grade 12x18H10T or 10x23H18.

The high percentage of chromium in these grades ensures the serviceability of the device even at very high temperatures. The disadvantage of such pipes is that the presence of chromium reduces the plasticity of steel, making the metal hard and brittle. Repair of such a product is extremely difficult.

For gas or wood-fired furnaces, experts recommend using pipes of the following grades: AISI 321 or AISI 316. At the same time do not buy a steel pipe brand AISI 439, as its service life is less than 10 years. Standard external dimensions of pipes from quality manufacturers have the following indicators: 197, 210, 280, 300, 350 and 400 mm.

Inner diameter, respectively, is 110, 115, from 130 to 145 mm, from 150 to 200 mm, 248 and 298 mm. The optimal option will be a pipe for the chimney with the indicators of external and internal diameters of 200 and 115 mm, respectively.

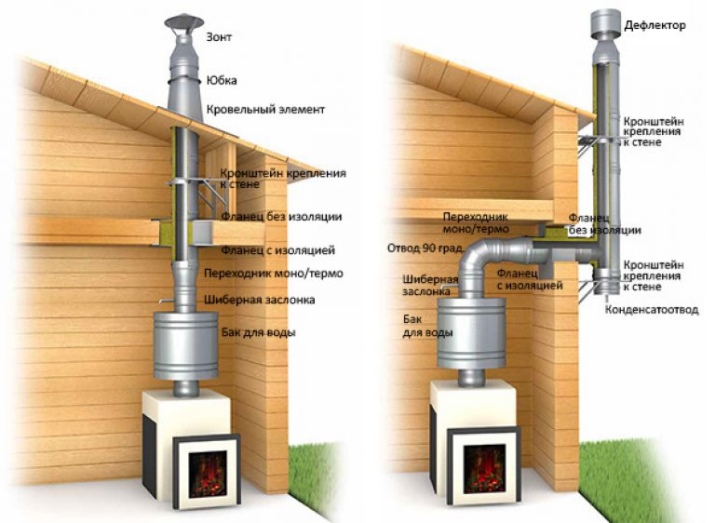

How to install?

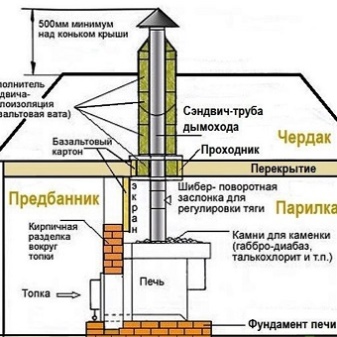

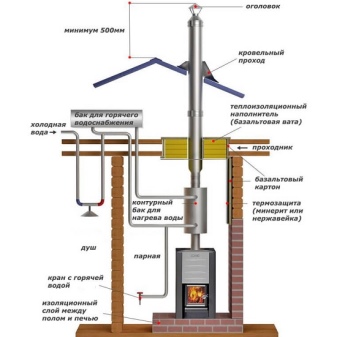

Sandwich pipe is absolutely fireproof, but still mount the chimney at a distance from any structure made of wood, such that will be safe. If the roof is made of flammable materials, then it is necessary to install a spark arrester on the pipe. Although the chimney assembled from sandwich pipes is easy to assemble, there are tricks:

- the inner diameter of the pipe should be chosen so that the connection point with the furnace spigots provided the maximum fit;

- joints of different elements should be placed so that they are in the zone of visibility;

- If the diagram implies the horizontal layout of some part, its length must not exceed 1 meter.

Before installation, it is necessary to make a scheme, and according to it purchase all the tools and supplies. The next thing we do is to mark the axis vertically, laying the axis from the smoke exit hole of the furnace to the passage through the ceiling and roof. It is necessary to take into account the location of the beams and rafters. Assemble the pipe begin at the bottom, making sure that the joint of the pipe is not in the ceiling overlap. If the project is to install structures that allow inspection and cleaning of the pipe, then this structure is located up to the attic room. Joints necessarily sealed and additionally reinforced with clamps.

Sealing also has its own nuances: inside the pipe sealant is applied closer to the insulation, the outside part is also applied closer to the insulation layer, and in the transition from the furnace pipe to the sandwich - applied to the entire circumference. In the attic, the chimney is installed in a metal box or apron, as it is also called. This is only one of the assembly options.

According to the second option, the pipe does not go through the roof, but through the wall - in it is also made a hole, which must be secured against fire. Outside on the wall there is a fixture, to which the sandwich pipe is attached.

The chimney is built up using two methods - "by smoke" or "by condensate". Let's consider both methods in more detail.

- "By smoke". The wide part of each new pipe is put on the narrowed part of the already installed, so the smoke comes out freely, and its seepage into the room is almost impossible. At the same time, condensate in this arrangement gets into the insulation, which violates its insulating properties.

- "According to the condensate. Assembly of the chimney according to this method is carried out on the contrary - in the wide part of the installed part it is necessary to put a narrow one. Smoke in this case leaves worse, but the condensate does not get into the insulating layer.

The chimney can be built using either the first or the second method, but it is optimal if the horizontal sections are built using the first method and the vertical sections are built using the second method. If properly designed, the chimney will ensure rapid heating of the steam room, maintain a microclimate and allow more economical use of fuel. The draught must also be controlled. Too strong leads to a rapid burnout of fuel, but the room of the steam room will not get warm enough. Weak draught leads to too slow burning process, when the fuel smolders.

After completing the assembly, it is necessary to make a test fire. In its process, it is necessary to inspect the entire pipe, while carefully checking the joints and the heating of the outer shell, as well as the surfaces closest to it.

Sandwich pipe - this is a great option for the chimney of the bath, suitable for all sizes of the sauna room. The device is easy to assemble, can be easily repaired or replaced with another option. In addition, such a pipe is inexpensive, and if properly installed, its fire safety is very high.

In the following video you are waiting for the connection of a wood stove to a sandwich pipe in the bath with a weather vane.