All about floors in frame saunas

The need to know everything about floors in a frame bath is due to the fact that they are very complex and require careful study. These floors can be put on piles or have a pouring device. Let's consider how to make a floor with their own hands in the washing room, steam room and other rooms, how to adapt it to the foundation.

Features

The main feature of the floor in a frame sauna is that it should be characterized by simplicity. The construction itself is relatively light. Therefore, it is usually built on a strip foundation or on screw piles. This directly affects the option of arrangement of the floor. In any case, you will have to take care about the insulation of the structure and its durability.

Floor in the bath must also be:

- comfortable;

- hygienic;

- resistant to water ingress;

- resistant to the formation of nests of mold and other fungi.

Types

The floor in frame structures can be constructed of wood or concrete. The first type is the most simple and convenient. It is very widely used in traditional Russian baths. Such a solution is characterized by naturalness and environmental safety. It is cheap and perfectly retains heat.

In addition, wood looks attractive. But it has to be carefully chosen and thoroughly prepared. There are many defects that wood can have. Of course, ignoring this point, the builders will face unpleasant surprises.

It should be understood that gradually the wood will lose its external appeal, and if prolonged contact with moisture will inevitably deteriorate.

The use of antiseptic agents can slow down this process. However, it can not be completely avoided. Arrangement of the floor in a frame bath can be carried out according to the flowing (leaking) scheme. Such an assembly involves the use of several levels:

- foundation;

- beams laid out at the top;

- boards laid out on the beams at intervals.

In this case, the water in the washroom and steam room through the floor pie will flow to the ground or into a pre-prepared drain. The disadvantage of this design is a strong supercooling of the rooms in the winter. Even special insulators do not always solve this problem. Therefore, in many cases, it is more practical to use a leak-proof type of floor. It is a monolithic boardwalk, put with a slope in one edge.

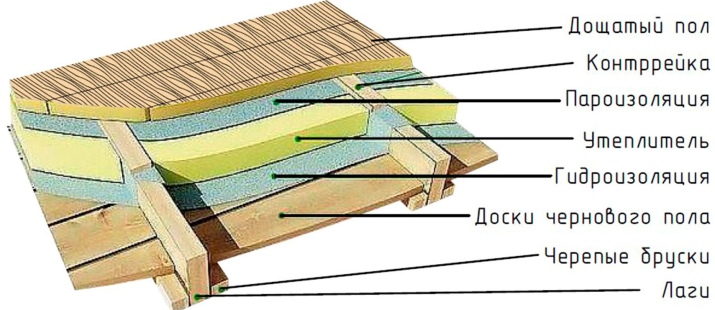

The lowest point of the plane is set aside for fixing the drain grate. Other points of drainage are not provided. The main components are:

- oriented slabs up to 0.6 cm thick;

- wind protection layer;

- a layer of hydraulic protection;

- thermal protection (mineral wool);

- thermal insulation cover (OSB);

- a couple of layers of polystyrene foam;

- vapor barrier;

- fiberglass-based reinforcing screed;

- concrete layer (with the addition of reinforcing mesh);

- boardwalk.

Some people prefer concrete floors.

They are distinguished by the high cost and complexity of execution. Such structures are durable and last for a long time. They remain functional under almost all conditions. What is important, concrete at any heat does not emit any harmful substances.

It itself remains resistant to systematic temperature jerks and prolonged contact with water.

It is worth bearing in mind that:

- concrete requires a very strong insulation;

- to build a floor of it quickly will not work;

- it is very expensive solution;

- over the planking will have to make a decorative coating, to make the appearance better.

The difference may also affect the type of foundation on which the floor is based. Structures on piles are built fairly quickly and require a maximum of one helper. They allow you to eliminate the use of complex formwork. As soon as the construction of the last hatch is finished, you can immediately begin constructing the bath building. Advantages of building on screw piles:

- stability;

- minimum time expenditures;

- long service life;

- mechanical reliability;

- ease of installation of sewage and plumbing;

- resistance to meltwater and soil water.

Pillar structures are also quite popular. Their depth may vary depending on the characteristics of the soil and the magnitude of the load.

The posts can be built from natural stone. However, such a solution, despite its reliability, will be quite expensive. Brick is available and quite reliable, but you will have to carefully choose the type of material.

Concrete blocks are not worse than bricks. They allow you to significantly simplify and accelerate construction. This solution is also very affordable in terms of costs. Another possible option - asbestos-cement or steel pipes. To give the structure maximum strength, it is saturated with cement-sand mortar from the inside.

How to choose depending on the foundation?

The type of foundation is mentioned for a reason: it depends on it how exactly the floor will be arranged. It is easiest to make it over piles. If any part of the plane sags, the correction of deficiencies is simplified. It is possible to perform the front floor in a leaking or nonleaking scheme, it depends on personal choice. The use of concrete is also possible.

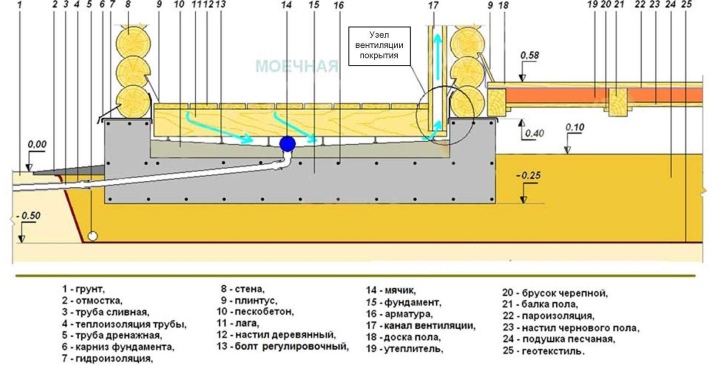

In a large frame bath is often used tape base. On top of them usually equip a concrete floor. In this case you need:

- a cushion of sand (to be compacted immediately after backfilling);

- waterproofing layer;

- insulation

- mesh with a reinforcing effect;

- concrete screed;

- facial decorative coating.

It is not often necessary to build a frame sauna on a slab base.

This is generally an expensive solution, in addition, causing problems with heat retention. In addition, through the plate can not run utilities. You have to lead them bypassing routes. But over the top of the slab you can form any kind of floor.

What is the right way to do it?

Of course, the easiest thing to do with your own hands is to make the flooring out of wood. The work begins long before you go to the site. It is necessary to calculate the necessary structures and fasteners. It is equally important to calculate the consumption of insulation materials of all types. Important: they should be taken with a reserve to avoid unnecessary problems and shortcomings.

To build a wooden deck, prepare:

- saw;

- screwdriver;

- self-tapping screws or nails (for laying on the joists);

- mallet for fine trimming;

- ordinary locksmith's hammer;

- paint brush;

- antiseptic.

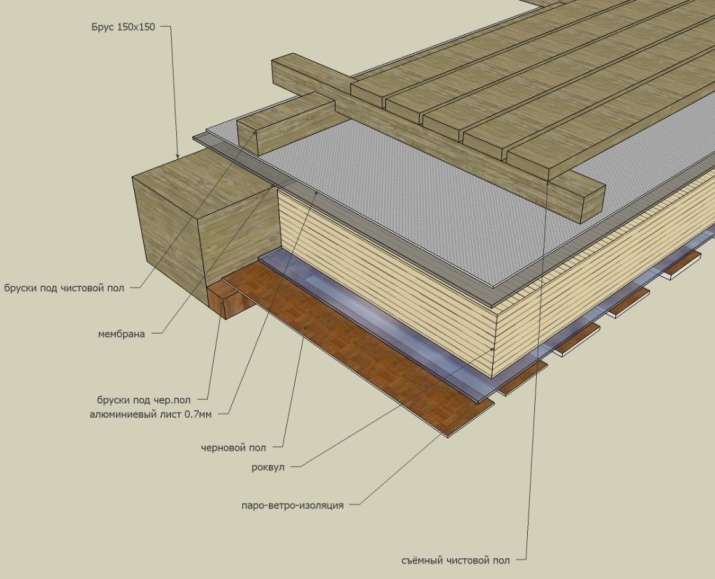

The first step in the work is to create a rough floor. Board or OSB boards are nailed to the outer side of the joists. Insulating materials are fastened using a stapler. The gaps between the joists are filled with slabs of mineral wool. On top of this insulation is placed a vapor barrier, the plates of OSB are mounted on it, and they are nailed battens, between which are placed panels of extruded polystyrene foam.

Further arrangement of the floor is usually carried out by nailing a suitable board with a slope to one side. In a more complex version, a reinforcing grid is put, and a screed is poured. Above the screed is the finishing layer of finish. It is necessary to think through and organization of the drain. To ensure that it will work smoothly, in any case, it is necessary in advance to determine the side for the slope of the decking.

The drain must be located in the lowest point. The drain is made of a plastic pipe. It necessarily leads outside the bath. Above the drain, be sure to mount a grid. It allows you to avoid the fall of the foot inside, getting there various foreign objects.

Waterproofing of the floor in a frame bath can be carried out at the expense of the coating composition. Most often this function is performed by bitumen, sealant. But you can also use special polymer varnishes, and plaster mixes. If the variant with laminated insulation is chosen, the surface must be primed before the work. Professional plaster waterproofing can be done with plaster, cement and polymer compositions. Solutions and mastics of different compositions are also sometimes used (this is called cast waterproofing).

Protection against rotting with antiseptics is certainly important. However, they must be used indiscriminately: the less synthetic and potent components, the better. Insulate floors in a frame building can be used with expanded clay, mineral wool, cellular glass, cement mixtures (to which various substances are added to improve quality). Select the insulation should take into account the budget of the builder, climatic requirements. Boards must be carefully dried.

About the arrangement of floors in a frame bath on screw piles, see below.