All you need to know about baths under shrinkage

Bath under shrinkage has both advantages and disadvantages. On the one hand - you will not be able to erect the structure on a turnkey basis, but on the other hand - measurements are the most accurate, and in the construction itself in the future there will be no defects. Below we will understand what you should pay attention to during construction work, what is shrinkage, how to minimize the negative effects, and what are the stages of construction.

What is it?

The term bath under shrinkage means that the construction, after the installation of roofing, remains incomplete from half a year to a year. The main cost of such a structure is determined by the partition and wall timber, as well as roofing and rafters.

In addition the price of the timber bath is doors, windows, insulation, stairs, finishing or roughing board. Other finishing materials during construction works are not taken into account. Structures that were made of profiled bar, over time, shrink. This is due to the fact that the wood dries and the insulating material is compacted.

In the first few months, a sauna with an attic can visually sag. You have to wait at least six months to see its true height.

It is recommended to pay attention to the following nuances when shrinking the structure.

-

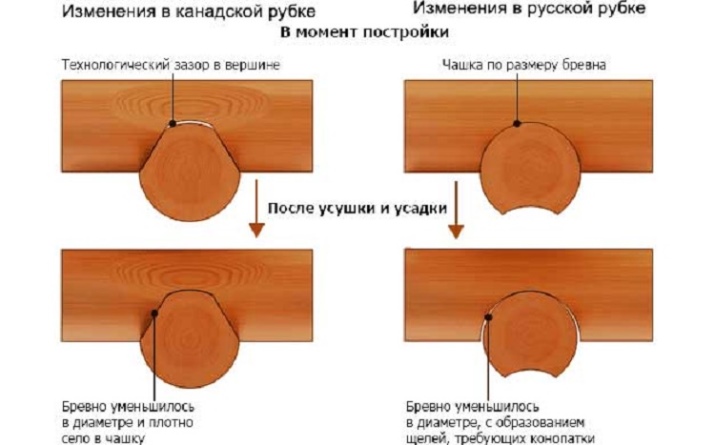

The cross-section can be reduced within 10% of the original size. The length of the product decreases to a lesser extent, so this point is not taken into account in practice.

-

If there is a high air temperature, and in fact not effectively ventilated, crackling occurs. In some cases, it is not excluded the rupture of the surface of the wood.

-

At moderate temperatures, when the drying technology is violated, the appearance of various defects of commercial timber is not excluded. For example, buckling, warping, and twisting are present. Depending on the type of wood, the defects will appear differently. This is based on the structure of the material (porosity, strength, order of occurrence, and other factors).

-

As the wood gradually dries, it hardens and becomes solid. The ductility of the material is lost, so it does not actually split along the fibers.

Building from a log when using a profiled beam will be reduced by 3 to 5 centimeters. Important condition - there must be a natural level of humidity, usually it is 30%.

If the log house used profiled log chamber drying, then the structure in its height will be reduced by no more than 3 cm. In this case, the humidity should not be more than 20%.

Overview of shrinkage

There are only two types of shrinkage of a building. They must be taken into account in the process of erecting the structure.

- Mechanical. Changes occur depending on how much pressure the structure itself will exert on its base. The greatest load is put on the lower veins of the log house. The size of the log cabin and its gravity will be reflected in the subsidence of the structure.

- Natural. It is based on the fact that the individual elements of the sauna gradually dry out. This way the construction can lose not only its height, but also its volume.

The first results of shrinkage will appear after 6 months. Since the log house does not dry out immediately (sometimes you have to wait up to 1.5 years), to estimate the final height of the structure in the first few months is not possible. If the sauna is erected on a turnkey basis, it will have both weaknesses and strengths.

-

The construction process is accelerated.

-

In a construction under shrinkage, the wood is carefully protected, because in fact it is not subjected to negative effects under the pressure of external factors. This is especially true for a period of six months to a year.

-

When a log cabin is erected under shrinkage, you can use during the construction of the material that is cheaper and more accessible on the market.

-

When erecting a turnkey sauna, it is assumed that finishing work will be carried out. They usually hide possible manifestations from shrinkage phenomena in the first months of the operation process.

It should also be taken into account that shrinkage may appear at the joints of the roof and ceiling, especially in places where the smoke channels from the sauna stove are located. The design should be done in such a way that the integrity of the padding and heat-resistant sleeve is not compromised during installation.

If there are several levels of layout in the bath, the project provides for the arrangement of an attic. In order to connect the floors, a staircase is erected.

Staircase structures are mounted only after shrinkage is visible, for this you will need to wait at least a year, sometimes you need a little more time.

To compensate for changes in the linear dimensions of the staircase, sliding fasteners are used while the structure continues to shrink. The connection is strong and the moving part can hold the mating surfaces securely.

Reducing the negative effects

In the case of natural shrinkage is almost impossible to minimize the consequences, because it is not known how much will decrease in volume and height of the log cabin. Mechanical shrinkage can be taken under control, and when constructing a building, calculate how many centimeters will be lost.

To reduce the negative effects, it is recommended to adhere to the following rules.

-

When using wood of natural moisture, the percentage of shrinkage will actually not be noticeable, especially if compared to glued variants. It is necessary to carefully approach the choice of wood, it is especially worth looking at its quality.

-

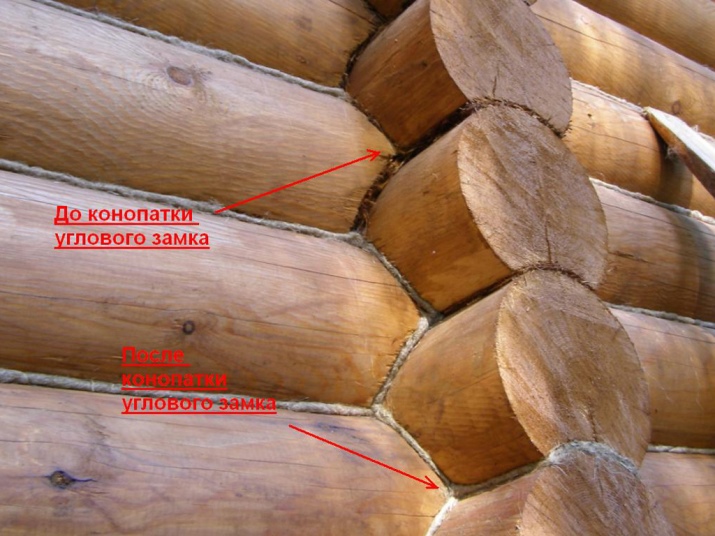

If you build a bath from a log, then the technology must be clearly observed. It is necessary to make minimal gaps between the elements of the structure, the adjacency should be made as tight as possible. This reduces the degree of deformation that will subsequently occur during shrinkage.

-

Since during the construction process the openings for doors and windows are planned, it is also recommended to take such details into account in case of deformation. For this purpose, indents of 3 to 4 cm are made in the upper part, bars are nailed on the side (cheap options should be chosen).

-

The ends of the logs are treated with special protective agents against precipitation. Additionally, it is necessary to provide for a high level of moisture and temperature fluctuations. Overlays of boards help to strengthen the resistance to external factors.

Whatever the methods used - you must be prepared for the fact that the structure will somehow give shrinkage.

That is why it is advised to leave the log building for some time, so that the elements had time to dry out and finally acquire their shape.

Assembly steps

If you properly follow the technology of construction, you can build a log cabin on your own almost without the help of specialists. Experience in the field of construction will not be out of place. Let's get acquainted with the scheme for the execution of works on the construction of shrinkage with the use of profiled beams (natural moisture), where the foundation has been prefabricated.

- On the foundation is laid the bottom strapping veneer. For this purpose, the thickest logs are chosen, on them after laying the remaining rows. In the area of the widest logs will require the installation of logs, which are used for flooring. Beams are connected "in a foot".

- Next, it is necessary to make the conclusion of the walls. If there are gaps between the logs, they should be laid with jute. The connection of the corners is made in the joint (there is also a variant with the use of radical cleats).

- In order to maintain a horizontal line at the future location of doors and windows, you must install vertical supports. In addition, it is required to take into account how the width of the openings will correspond to the planned project.

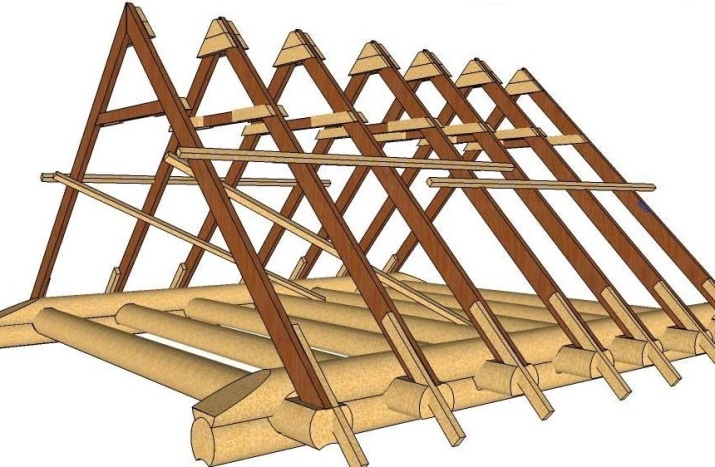

- Once the walls are ready - you can start laying the ceiling beams. They are fastened to the mauerlat, which is made from a thick beam and fixed with the top rows.

- After the mauerlat is fixed, it should be connected to the rafter system, which has the struts. The rafters are placed at an angle and fastened with a ridge beam. To close the end parts, a special frame is used, on the same is located the internal insulation.

- To mount the selected roofing material, it is necessary to work on securing purlins over the rafters.

To fasten the wooden elements, dowels made of wood or metal are used. It will look better if the structure, including the dowels, has a wooden base.

See below for an overview of the shrinkage bathhouse.