What are the partitions in the bath and how to install them?

When building a bathhouse, it is important to take into account a variety of nuances, established regulations and rules that determine the subtleties of installation of various functional blocks of construction. In our review, we will tell you how you can independently build partitions in the bath so that the bath is not only comfortable and ergonomic, but also as safe as possible.

Materials

Partitions in the bath are built to separate the steam room and the sink, they separate the furnace and separate the rest area.

It is very important that the internal walls in the sauna were built not just with respect to the design of the room, but also took into account the parameters of load-bearing structures.

The material used in their construction is of fundamental importance for the further operation of the sauna. For example, the wall around the stove is usually made of brick or foam blocks, but the steam room from the sauna room traditionally separated by a wooden structure.

Brick

Traditionally, brick partitions are built in brick, as well as block buildings. In wooden baths they are much less common. The explanation is quite simple. All log cabins after a few years begins to shrink by 5 or even 7-10 cm, and the brick wall remains in its original place, and this can cause a significant warping of the structure.

In addition, Brick heats up much slower than wood. That's why in wooden buildings prefer to build board walls. The only exception are situations when it is necessary to cover the furnace, located in the anteroom.

In this case, the partition must be as fireproof as possible and able to withstand the highest temperatures.

Brick has its pros and cons. The advantages include:

- high parameters of noise insulation;

- moisture resistance, and therefore reducing the risk of mold and mildew;

- fire resistance material.

In addition, bricks are of no interest for insects. However, we should not forget about the disadvantages. Among them:

- Significant weight of the construction;

- the duration of the construction work and the labor intensity of the process.

The disadvantages include the fact that the brick wall before finishing must be plastered.

Wood

In rustic log baths, walls made of wood are traditionally built. Such a partition, like a brick one, has its positive characteristics:

- eco-friendliness, due to the safety of wood;

- relatively low weight with a rather significant thickness of the partition itself;

- wood soundproofing parameters.

The use of timber frame construction adds to its durability, so that the partition wall can withstand heavy loads. With such an impressive list of advantages, it is worth remembering about the disadvantages.

First of all, it is the hygroscopic nature of wood, which causes deformation of the material, contributes to the appearance of mold and mildew, as well as rot.

To avoid such unpleasant consequences, the partition requires the application of a waterproofing layer and the use of special impregnations. Wood has low rates of fire resistance, which significantly increases the risk of fire. All this narrows the scope of use of such partitions - they are erected mainly to separate the steam room and pre-bath, near the stove it is preferable to use other, more durable materials.

Any wooden partitions must be treated with flame retardants before use. And, of course, to the disadvantages of the material include its attractiveness to insects, so it needs mandatory application of antiseptic coating.

Glass

Glass walls look very effective and stylish. They are made of blocks not less than 7-10 cm thick. Their surface can be not only transparent, but also colored and fluted or matte. The advantages of glass blocks include:

- decorative appearance;

- the ability to let in rays of light, and if we are talking about modules with corrugated coating - they additionally create an interesting play of light;

- High noise insulation characteristics.

Glass is inherently fireproof material, so such partitions can easily withstand frequent temperature fluctuations.

In addition, the material does not let hot steam and water through and is not damaged by insects.

There are also disadvantages:

- on the glass partition it is not possible to fasten shelves or any other functional elements;

- during installation it is impossible to cut off a single element of the single structure;

- the glass surface completely eliminates the possibility of running utilities through it.

Made of foam block

Walls made of foam concrete or aerated concrete are not afraid of moisture. In addition, they are durable and help to retain heat inside the sauna room. This material is foamed concrete. In recent years, such partitions have been very popular with bath owners, because samples only 10 mm thick can withstand temperatures up to 800 degrees Celsius for two hours without signs of destruction.

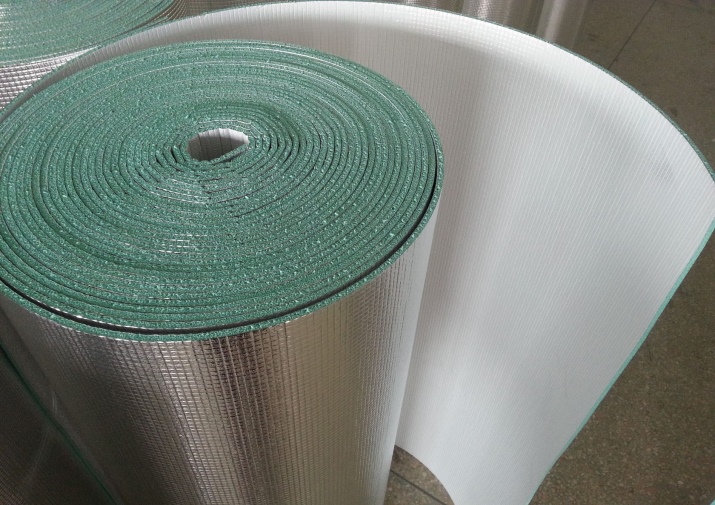

However, you should keep in mind that when constructing such a partition near the metal stove, it is necessary to leave a gap of at least 1.5-2 cm. The wall of foam block must be additionally insulated with mineral wool and covered with a sheet of stainless steel - it should not be left uncovered. In the steam room, concrete blocks are insulated with foil insulating material, then a crate is put on and the top is covered with aspen or lime linings.

Device

If we talk about what type of partition walls will be optimal for bath rooms, the most popular option is a frame wall. It is used in the installation of wooden partitions. The frame is usually assembled from carefully dried beams, their typical size is 5x5 cm. In the voids formed between the structural elements, fix a layer of any insulation - usually a foam board or mineral wool.

It is important that the insulating material was reliably protected from the adverse effects of water and steam.

To this end it is closed with a layer of any waterproofing material - most often in course is the usual polyethylene film, although if available funding is better to choose in favor of special membranes with high waterproofing characteristics. In terms of their operating parameters they outperform polyethylene, however, and the price is high.

Insulated framework is covered with dried boards with a thickness of at least 2-3 cm. Fix a foil layer on top, for the most accurate fixation use a construction stapler. The use of foil is very important for the retention of heat energy - in the room it has the property to redirect the heat radiation inside the bath. Instead of foil, you can use foil or other similar material with similar characteristics.

The outer layer is a decorative cladding of the wall. Most often used for this purpose cladding, the best solution for the bath is considered lime, and aspen wood, because when heated, these materials do not release resin, unlike softwoods. To install the battens on the frame put laths in the form of conventional battens.

At the same time All wooden elements of such a structure should be treated with special antiseptics. If you do not take care of the protection of the material in advance, then in a very short time it will begin to rot, mold and fungus will settle on it. From a structural point of view, this partition is a kind of pie of building materials - from the outside it looks very aesthetically pleasing.

How to do it right?

A frame wall today is a very popular solution when separating one functional room of the bath from another. That is why we will elaborate on the issues of its installation. Particular attention should be paid to the preparatory work.

Previously, all the walls, ceiling and floor in the room are thoroughly cleaned from dirt, paint, as well as the remains of any building materials and leveled. In addition, it is necessary to prepare a wooden formwork for the frame structure, to remove debris and purchase all necessary materials for the work. Only after this, you can move directly to the construction of the partition wall. The work includes several stages.

- First, it is necessary to saw blanks for the frame base, make narrow holes in them and fix them.

- To erect the supporting frame, it is necessary to make the edges of the posts on the base and fix them with fasteners.

- To formalize the doorway for the frame installation, you need to align the uprights vertically, while leaving a gap on both sides at least 1.5-2 cm larger than the parameters of the frame.

- The lintel of the frame is attached to the boards with self-tapping screws.

- Next you need to equip the crate, to insulate the structure and cover it with a layer of insulation material and a waterproofing film. Then you only need to lay the purlins with a spacing of about 35-50 cm.

The most difficult stage is to install the door in the opening. The frame should be installed in such a way that there is a small gap of 1.5 cm on all sides. After installation, you need to make sure the exact verticality and levelness of the structure.

All gaps left during the previous stages of work are treated with construction foam.

It is important to keep in mind that all parts of the opening that are open to the shower room must be covered with planed boards. In the final step, the only thing left is to cover the wall with battens. To do this, the stud of each subsequent element is fixed in the groove of the previous one and fastened with nails without caps.

If you intend to build an interior wall of brick, then you must first prepare the interior room - to cleanRemove all unnecessary items, put a bright light. From the walls and floors need to remove all wood covering and clean all surfaces. Next, on all components of the structural box is necessary to mark the contours of the partition. A step by step guide to the construction of a brick wall involves several stages of work.

Sand is mixed with dry cement in the ratio of 3 to 1. Cold water is added in a small trickle to the prepared mixture until the composition acquires a homogeneous plastic structure. To masonry brick partition wall in the bath was made as evenly as possible, it is desirable to stretch a tape along the line of its edges. In addition, you must from time to time check the verticality of the level.

The door frame in the opening is put in advance, it is extremely important that the brick fit tightly to it.

Masonry performs using the method of dressing the joints, for this every second row begins with the laying of half a brick.

Large gaps near the ceiling are caulked with hemp. If the wall is installed in the sauna room between the steam room and the washing room, it is desirable to protect the brick with tile on the side of the shower. Such a solution will minimize its wetting and reduce the degree of wear and tear.

Beautiful examples

The question of installing a partition in the bath with his own hands has long gone beyond the boundaries of ergonomics. Today these constructions not only divide a room into several functional zones, but also become a decorative element, emphasizing the stylistics of the room.

The unshakable classic - wooden partitions, they look original, perfectly fit into the eco-style, country and ethno style baths.

Glass walls look very modern in contrast to them. Glass is usually used matte or fluted, but lovers of non-standard solutions can use and transparent material.

Very original look brick partitions, to make them more decorative they are often finished with stone.

How to make a partition in the bath, see below.