All about the vapor barrier in the bath and sauna

One of the most important tasks of a modern bath is the ability to retain steam inside, in order to provide the most favorable microclimate in the room. That is why in the process of arrangement of the bath close attention should be paid to the device vapor barrier.

Waterproofing the bath or sauna of a bar with their own hands should be carried out with all the building requirements and recommendations of the manufacturer of materials.

Features

The bath is a building with extremely high temperatures and humidity levels, which often leads to the formation of condensation.

A well-designed steam insulation system will achieve optimal removal of moisture from the inside, thereby prolonging the life of the blood and walls.

Insulation should be used for the entire facility at once: the basement, the foundation and even the interior floors. Quality vapor barrier insulation is used at such times:

- When there is too much vapor that could end up in other parts of the steam room or escape to the outdoors;

- When the cause of moisture is a sudden change in temperature, resulting in condensation.

In order for the vapor barrier to be high quality and reliable, it is worth adhering to the following recommendations:

- For the steam room, the ideal solution is to use materials based on foil, which allows you to reflect and collect heat;

- For the washing room, it is best to use foil materials, which are characterized by affordable cost and high efficiency;

- in the relaxation zone a membrane insulation is laid.

Choice of material

The selection of means for the waterproofing of the bath is a responsible moment, because it depends on it, how effective the system will be. The usual materials, which were often used before and are used now, include Kraft paper and polyethylene film.

Films

The choice of material depends on exactly where the system will be installed. For example, if we are talking about the walls, you can be limited to an affordable film that can boast about its efficiency to retain heat, while providing reliable protection for insulation against getting wet.

The main advantage of polyethylene is resistance to moisture, as well as the lack of difficulty in the process of laying. This method is considered the cheapest, but it has certain disadvantages. Such a product cannot boast of its durability. Under the influence of high temperatures, the film quickly loses its properties, so in the bath itself its use is not considered effective. The best way it shows itself in the pre-bath.

Before buying the film it is necessary to check its suitability. To do this, we fold it in half and look whether the seam will be visible.

If there is such a seam, it is worth to refuse from such film at once - it can spoil rather quickly due to high temperatures indoors. Ideal film even after folding remains flat.

More advanced means of protection against moisture is considered polypropylene film, which perfectly copes with elevated temperaturesThe material is not lost to the effects of heat or ultraviolet light. In addition, this material is not deprived of its benefits due to thermal effects or the influence of ultraviolet light. That is why very often such a film is used for exterior cladding of the bath. In this case, the material is quite affordable cost, which is not much higher than the price of polyethylene versions. A distinctive feature of polypropylene film is also its impressive porosity, through which it can withstand a lot of moisture.

Another material that is often used in order to protect the bath from water vapor is Kraft paper. This raw material is a special cardboard that boasts high density and strength. It is because of these properties, the material is able to retain steam, thereby protecting the insulation. The material is not suitable for the steam room itself, but for the decoration of the recreation area it will be quite sufficient. However, the use is possible only when there are no places in the room for the shower, as the paper will quickly get wet and become unsuitable for further use.

For finishing the steam room, some people still prefer to use roofing felt or parchment. However, such materials should be preferred only if there is no access to other materials. Of course, to their moisture protection properties no claims, but the composition of these products include hazardous substances that can harm human health. In addition, when exposed to temperature, the materials begin to emit bad odors, which negatively affects the comfort.

Membranes

Currently, membrane vapor barrier is considered one of the most effective and optimal materials.

- It is actively used in the process of vapor barrier walls and ceiling in bath complexes. The uniqueness of the considered raw materials is that it has two sides. The first reliably protects the insulation from the effects of moisture, while the second is breathable. It should be noted that in the market you can find both one-sided and two-sided options, so when finishing you need to clearly understand which side should adhere to the covering.

- Membrane vapor barrier can be both single layer and multilayer. The latter option is considered more optimal, but is characterized by a high price. The main advantage of a multilayer membrane is that moisture accumulates inside it, and during the cooling of the steam room begins to evaporate.

- The most innovative type of membrane is called a smart membrane. The distinctive feature of such a vapor barrier is multifunctional, thanks to which you can not only control the level of humidity, but also to accumulate heat. In addition, this material can easily be used as a full-fledged waterproofing layer. The cost of a smart membrane is quite high compared to other materials, but given the quality and ability to replace many materials, the application becomes justified.

It should be noted that the membrane of each manufacturer may have its own characteristics, so it is worth reading the instructions.

If there is no packaging, the initial point is to identify the smooth and rough half.

The fact is that it is the impressive porosity that guarantees the absorption of excess moisture, as it is characterized by its absorptive qualities. Therefore, this surface should be directed outward.

Foil

Such materials are on the market in a large assortment. Users claim that they are the most optimal for protection against moisture. The unique composition provided the material resistance to extreme plus temperatures and their sharp fluctuations. Even with prolonged exposure, such products do not lose their characteristics and continue to perform their functions. Foil vapor barrier also boasts the ability to reflect infrared rays, which provides rapid heating of the steam room.

On the market today you can find many options for such a vapor barrier.

- Kraft paper. It is considered a more preferable option than conventional foil, as it can boast of better strength characteristics. A significant disadvantage of such a product is a high level of hygroscopicity, which often becomes the cause of soaking. This can not only contribute to the rapid deterioration, but also lead to the formation of mold. That is why bath owners have been gradually abandoning this material in recent years.

- Kraft paper lavsan. Is one of the most durable materials with foil, which is able to retain its performance properties even at extremely high temperatures. The disadvantage is the presence of non-natural components in its composition. The fact is that it is best to use natural materials for the bath, which are considered safer from an environmental point of view.

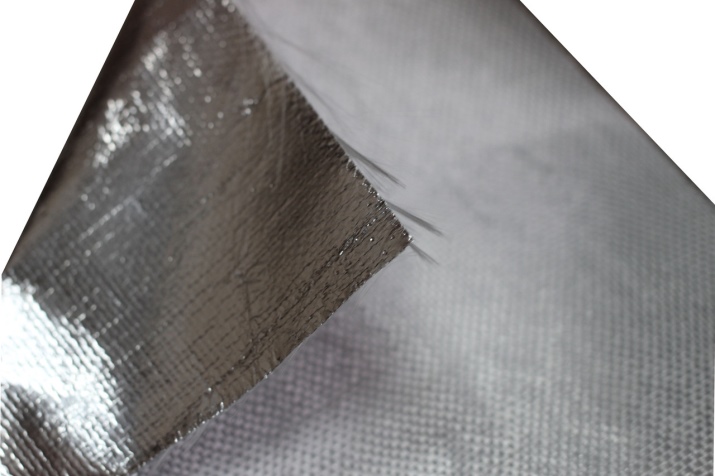

- On the fiberglass base. This material is considered one of the most expensive on the market. Its advantage is in a strong base, which does not rot or deteriorate even after many years. In addition, properly laid foil membrane on the fiberglass base will play the role of a thermal insulator, thus becoming an additional insulator.

- Thermal insulation with foil. This material has a thermal insulator and a special side for vapor barrier. The role of insulation is usually performed by mineral wool. The use of such material allows you to save money and time for finishing work.

Another popular type of vapor barrier is the coating, which is a liquid rubber. The main advantage is that the product consists of advanced polymers that create a special waterproof film.

It differs not only in its vapor barrier properties, but also in its thermal insulation characteristics.

Due to such features, this material and is considered the most effective for finishing the floor. In addition, it can boast of versatility, so it is actively used not only for wooden but also for concrete floor.

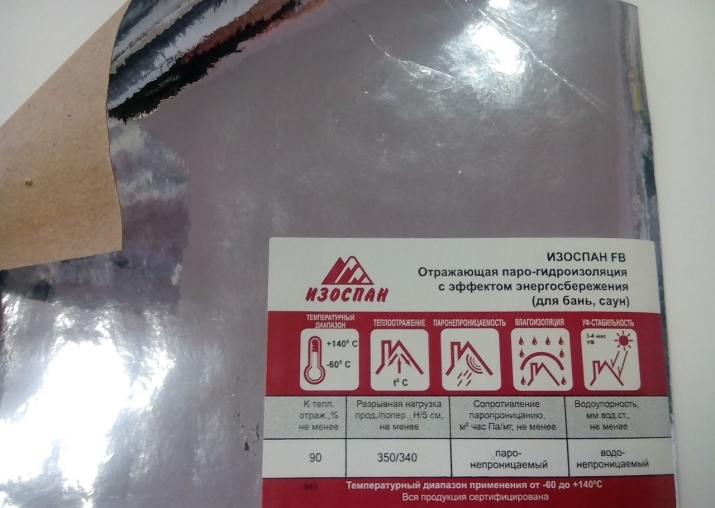

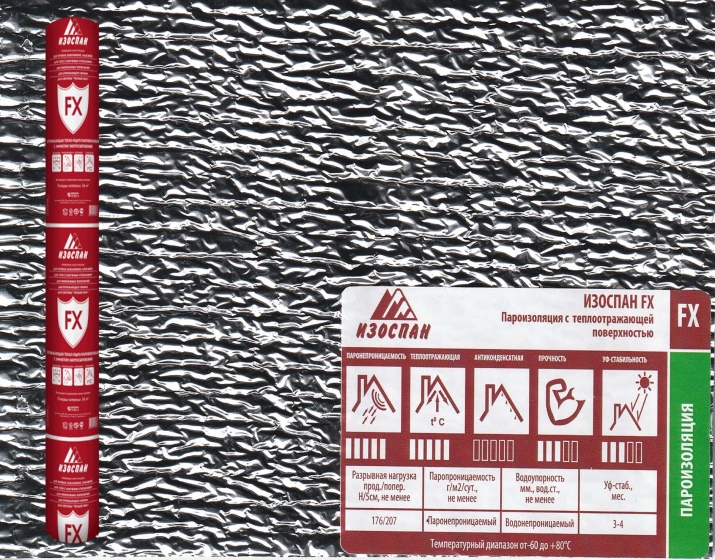

One of the most high-quality and effective means today is considered isospan. Over the years on the market, the company for its production has managed to prove itself on the positive side, proving the effectiveness of its products. Among the most in demand are three types.

- FB - the most popular product on the construction market, which is actively used for the vapor barrier walls in the bath. It is based on Kraft paper, which is also covered with foil. A distinctive feature of the product is a metallized layer, which does not let the moisture, as well as reflects the heat, thereby helping the insulation.

- FX - polyethylene with a metallized surface is used as the basis. Thanks to this material is considered versatile and suitable for any surface.

- FS - is a membrane fabric, which plays the role of not only a vapor barrier, and insulation.

For a log bath it is easy to carry out all the work, but for a frame or gas concrete steam room it is more difficult to choose a vapor barrier, because you need to take into account the peculiarities of these building materials.

How to make a vapor barrier?

Effective vapor barrier will provide reliable protection for insulation against moisture. It should be noted that regardless of the type of material used, the process of laying it is as follows:

- carrying out preparatory work, which includes getting rid of debris, dust and other contaminants on the base;

- placement of waterproofing and insulation - here it is necessary to be extremely careful, since the comfort in the bath and the degree of heating of the room depend on it;

- Installation of vapor barrier and decorative finish.

Ceiling

In the process of conducting finishing work is necessary to pay close attention to the ceiling.

The peculiarity of the bath is that it generates a huge amount of steam, which rises above. That is why the greatest load is on the insulation, located on the ceiling.

The ceiling more than the walls and floor requires careful vapor barrier and treatment with special materials.

- The ceiling is finished with boards, the thickness of which should not be less than 6 cm. On top of this is laid a foil material with a density of 100 microns or more. For better performance, you can additionally treat it with olive oil.

- Now a layer of softened clay is laid, after which the insulation itself can be laid.

- On top of the vapour barrier, the insulation is carefully placed. Mineral wool is considered the ideal material for this. If you need a seamless version, you can be limited to keramzite filler.

- After laying the insulator on it is also necessary to put a moisture-proof membrane that will not allow moisture to the insulation.

Walls

The walls represent the most extensive area of the bath, so their finishing requires the use of a large amount of material. The vapor barrier process for the walls in the steam room consists of five steps.

- Creation and installation of wooden battens, which should be thicker than the insulation.

- Installation of thermal insulation materials between purlins. Mineral or glass wool can be used as such material.

- Laying the vapor barrier. Here it is necessary to be extremely careful not to allow heat loss in the future. Installation should be done from the far corner, and the edges of the film should be fixed with an overlap. The joints must be sealed with scotch sealant.

- Careful attention should be paid to choosing the right side of the material for the vapour barrier. It is necessary to direct the heat-reflective base to the inside of the room.

- On the membrane also need to install a crate of wood, in order to achieve thus the natural circulation of air.

Floor

Floor vapor barrier depends on the design features of the steam room itself.

In most cases, such objects are characterized by the presence of wooden flooring, which is a source of large heat loss. The only solution to the problem is to use several layers of vapor, thermal and waterproofing.

Flooring treatment work includes:

- applying a liquid waterproofing base to the wood flooring;

- laying of basalt wool, which will play the role of a high-quality insulator;

- placing vapor barrier material, which is characterized by resistance to decay;

- Conducting concrete screed, after which you can lay porcelain tiles or any other coating, taking into account the characteristics of the steam room.

In order to ensure the most comfortable use of the bath, you can lay a wooden deck on the base of the floor.

Vapor barrier roof is not usually carried out, as the internal work is enough to create a comfortable microclimate inside.

Thus, The process of vapor barrier in the sauna includes many steps and requires the utmost care. One of the most important points is to choose the optimal material. To do this you need to consider not only the structural features of the room, but also the degree of its heating and the amount of steam produced. Properly done vapor barrier will provide a high level of comfort in the steam room, as well as reliable protection for insulation against moisture. Mount the vapor barrier from the inside should be based on a predetermined scheme or plan.

How to mount a foil vapor barrier in the bath, see below.