How to make a steam room with your own hands?

Arrangement of a country or suburban house, adjoining buildings - it is a whole art in its own way. However, knowledge of simple recommendations can significantly simplify the task. It is very important to know, for example, how to make a steam room with their own hands, and what to pay primary attention.

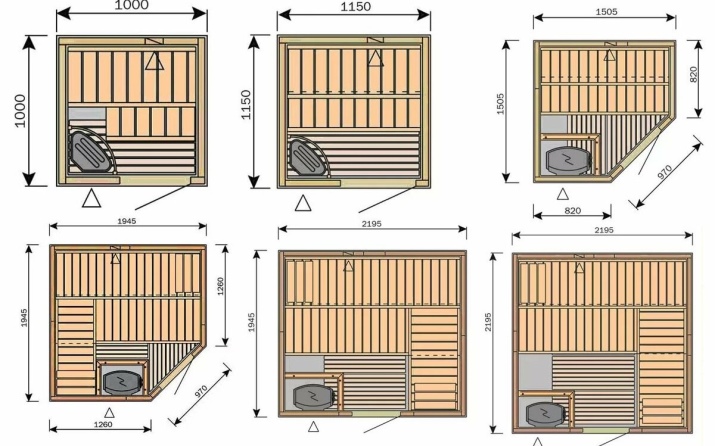

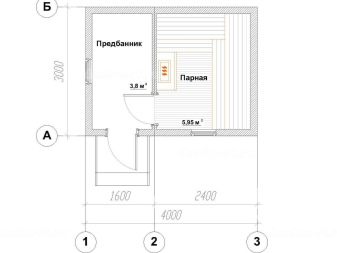

Choosing the project

Before engaging in any construction, it is necessary to choose clearly and accurately the general approach. In this case - it is a selection of the drawing among those available on the Internet, or prepare it yourself.

In the vast majority of cases in the arrangement of the steam room with their own hands in the bath choose all the same proven many decades of the traditional Russian furnace.

It becomes the semantic center of the room, around it builds the entire composition. Thinking through any project, you need to clearly answer the questions:

-

What will be the allotted space;

-

how rationally it will be used;

-

how to finish the room from the inside;

-

what material to choose for the main load-bearing structures;

-

how to insulate the room;

-

what provides waterproofing, vapor barrier, windproofing.

There is no special alternative to classic sauna heaters in small-sized baths. It is worth to take into account that they can have different variants of heating stones. In addition to conventional wood-burning stoves, there are instances that run on gas, electricity and even liquid fuel. Stoves with heat exchangers are a good alternative - however, they do not allow to observe the tradition. It is also possible to use:

-

A gas-fired boiler;

-

electric boiler;

-

wood boiler;

-

boiler of a combined type;

-

electric convector;

-

heating cables;

-

infrared film.

Materials for arrangement

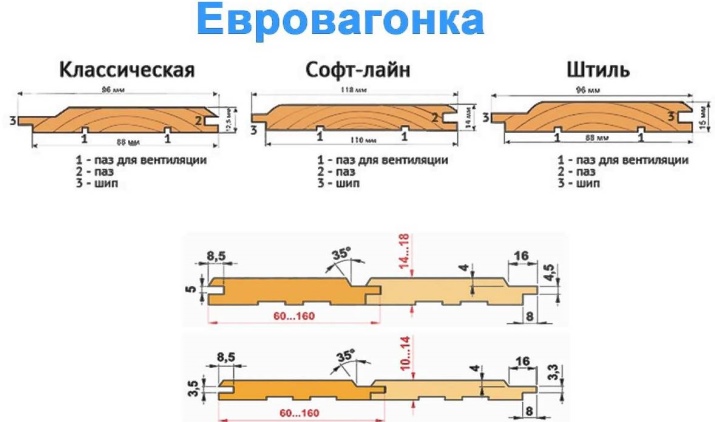

However, no matter how warm the air is, bad finishing materials can cause inconvenience. The connoisseurs have long noted that the best shows itself is batten. It will provide perfect air circulation. You will not have to pay much for the batten itself and its installation. And if you do everything with your own hands, then there won't be any special difficulties either.

Those who choose this material will be rewarded with an even more attractive appearance and the absence of unpleasant condensation. It is recommended to use hardwood rather than softwood. The walls will warm up faster, but will not cause burns or even just unpleasant feelings when touching them.

If we talk about individual species, then here the best choice can be considered larch. However, we must understand that this material is very expensive.

The use of linden birch felling is also allowed. Its only disadvantage is the need for treatment with a special compound. Otherwise, the original color will quickly be lost. Hard aspen is not bad for the ceiling and walls. But on the floor, it does not look too good.

Ash wood is strong and resistant to rot, in addition, its middle part allows you to achieve a good external effect. In addition to these options, you can also apply:

-

African abasi oak;

-

poplar;

-

aspen;

-

Alder (which also guarantees the exclusion of bad smells);

-

white acacia.

If you do not like the linings, you can also use:

-

edged board;

-

unedged board;

-

planed board (mainly for brick buildings);

-

block house;

-

ceramic.

Step by step instruction

Floor Installation

For normal operation of the steam room, it necessarily needs a drain. In Russian baths, you can use both leaking and nonleaking floor. The second option is more complicated, but it is much more practical and convenient, and sometimes more aesthetically pleasing than just a sawed gap.

It is possible to arrange nonleaking face floors on both wood and concrete subfloors. This will not even have a significant impact on the technology of cladding.

The runoff itself must be gravity-fed. Special measures are taken to ensure that water does not enter the main structures of the floor. A very important role is played by insulation from the inside. In order to do the job properly, you need to consider the basic requirements:

-

quick drying of the surface;

-

ease of draining water without additional effort;

-

preservation of heat;

-

ease of cleaning;

-

hardness of the surface;

-

minimal risk of slipping;

-

a sense of tactile warmth.

Most often, the lower (rough) floor is created with cement, sand and sand-gravel mixtures. Over this substrate lay insulation, reinforcing mesh and screeds. The order of "layers" in the "pie" can vary. Recommendation: Consider the different options for underfloor heating.

The front finish is made of wooden beams or boards, the size of which is chosen at your discretion.

Wooden floor is recommended to treat with compositions that reduce resistance to rot. Some people choose options with brick, tile floors. But regardless, it's worth surrounding the drain with a grate and siphon so that water can escape in an orderly fashion. It's helpful to note that the most budget-friendly solution is to form a rough concrete base with a wooden leaky "face."

If you don't think about aesthetics, this is an ideal solution when funds are severely limited.

For insulation, concrete with special additives can be used over the mesh. Most often such an additive is crushed polystyrene foam. The total layer can be at least 3-5 cm. Some builders insulate the steam room from below with boards of EPPS. Over the "thermal" layer, in any case, an additional cement screed is placed.

Vapor barrier and ceiling finishing

It does not matter whether you build a sauna with an industrial or homemade stove, no matter what kind of hearth is used - in any case, you will need high-quality vapor insulation of the top. Even in log saunas, the ceiling of the steam room from the inside must have adequate protection. The walls are equipped with it, if the insulation is made with mineral wool and other leaking substances. Foamplex, foam plastic have no such requirements. The easiest way to insulate the ceiling from the steam itself with films.

The difference between rough and smooth modifications, in fact, is not so much, no matter what the manufacturers say. Non-woven membranes are also used quite widely. They are quite good at containing liquid moisture and condensing liquid.

But the most ideal solution for the steam room experts consider foil materials. Their special coating allows a guaranteed saving of heat, which is especially important in the middle zone and the more northern regions.

Speaking of specific options, it is useful to note:

-

Kraft paper;

-

polyethylene (the most mediocre option);

-

polypropylene film;

-

Ruberoid and asphalt felt (extremely harmful and will soon be out of use);

-

Cladding vapor barrier (reliable, but creating a lot of problems when working).

To properly finish the ceiling of the steam room in the front version, you must first detect the problem areas with the help of an angle. Small defects can be eliminated by shifting the linings for a few millimeters at the joints. Serious deviations are corrected by trimming the last piece of batten at an angle. Finishing materials for the face layer should be purchased with a 10% margin over the area. This is important because no experience and no quality of the original products will not insure the need to perform trimming.

The batten is either countersunk in the groove, or openly - in the flat parts of the boards. This determines the size of the nails used. Open nailing is much preferable, especially for inexperienced builders. Do not forget about the frame of asbestos and mineral wool around the chimney.

Important: trim the ceiling should be, leaving the edges free; by stuffing the skirting there, irreversibly violate air circulation.

Here are some more recommendations:

-

Do not use regular, but eurowoods;

-

leave the foil "overlap" to connect to the foil on the walls;

-

Avoid classic plank ceilings (they have more negatives than pluses);

-

bypass the chimney as far as possible (0.2-0.3 m) wooden structures of any kind.

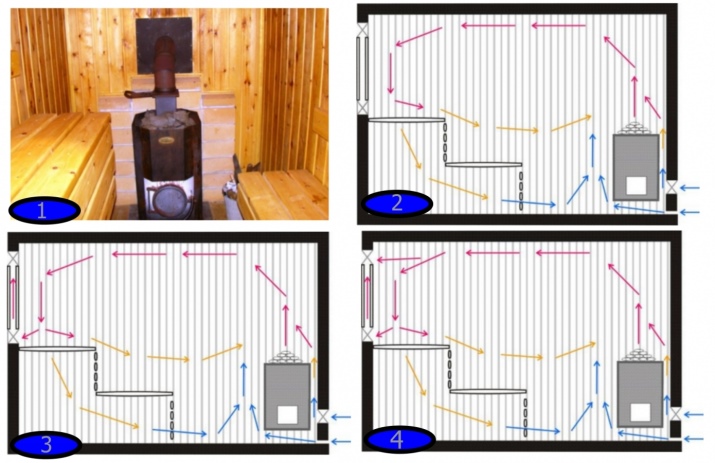

Ventilation and electricity

In popular manuals on the construction of baths, these points are often bypassed - and quite in vain. To give up the same ventilation completely is possible only in old-fashioned log cabins without any insulation. But then the flow of fresh air will be achieved at the cost of overcooling the room. Today, doing without ventilation is not cheap, but on the contrary, very expensive. Without proper air circulation every 8-10 years you will have to rebuild your bath almost from scratch.

Another important thing is that you will quickly get an unpleasant odor. And formed colonies of fungi, rotting, will create a health hazard. Carbon dioxide and sometimes carbon monoxide buildup should not be forgotten either. The location of the vents and air intake ducts must be considered during the design and initial construction phase.

It is necessary to equip the ventilation ducts with shutters; the cross-section of the vents should be selected according to a simple rule - 1 cubic meter of volume corresponds to 24 square centimeters of the ventilation duct.

Natural ventilation does not allow the steam room to fully perform its task. Much more practical mechanized and combined systems. But the second option is used more often, because it is more profitable. It is strictly forbidden to locate the outlets of the inflow and discharge at one height - this will turn into a draught. Another important point - ventilation of the floor, without which you can not achieve a good microclimate.

In the steam room you will also need to create a well-thought-out wiring. When preparing it you must take into consideration PUE regulations. Considering the safety standards, it is easier not to save money and lay the cable underground. It is recommended to use VVG, NG or foreign NYM cables inside the steam room (and the bathhouse in general). Important: The specific wiring scheme is determined by a specialist for each specific sauna building.

Sectional standards for 16 A current is 1.5 mm², and for 40 A - 6 mm². It is extremely important: Only copper wires may be used in bathing facilities.

Smaller cross-sections are connected to larger ones, not the other way around. The most powerful circuit breaker is placed at the beginning of the electrical circuit. It is required to use electrical equipment and cables with protection level IP24 or higher.

Insulation of walls

Thermal insulation in a brick bath, especially when using artificial stone for finishing, must be done very carefully. The protective layer should be mounted from the inside. Whether to supplement it with external protection is a matter of taste. Heat retention is ensured by a special plaster or an additional timber wall. In a wooden steam room, basalt wool is mainly used.

Styrofoam insulation is completely unacceptable. This material releases toxic substances when heated. Trusses are made of slats or aluminum. Thermal insulation work in frame baths also has its own characteristics.

There are widely used mineral wool boards. But you can also use reed board, a mixture of gypsum and sawdust.

Experts recommend laying two layers of thermal protection inside the frame. Here are a few more recommendations:

-

Distinguish between the inside and outside of sheets, foils;

-

Do not use asbestos near stoves;

-

On the walls between the sheathing and vapor barrier is not allowed spaces, but on the ceiling they are necessary.

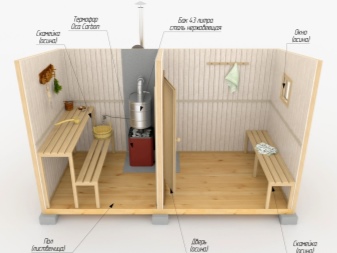

Furnace installation

Installing a wood-burning stove is simple. But it, like any other heat source, must be placed taking into account the requirements of fire safety. The distance to the supporting structures and all wooden elements must be at least 1.1 m. The work starts step by step with the arrangement of the base. The concrete surface allows you to put any kind of stove.

To make cleaning the steam room more comfortable, the hearth area is finished with tiles, chamotte or porcelain stoneware. The base must be at the depth of the main foundation. But at the same time, it is performed autonomously from it, otherwise the normal shrinkage is unattainable. If it is not possible to remove the stove to 0.5 m from the walls or more, it is required to use a non-combustible finish. In sequence:

-

put a hinged tank on the nozzle;

-

a heat exchanger is put in place;

-

Prepare supply piping;

-

fix the chimney.

Installing the doors

To build a bathhouse and even equip it with a stove is not enough - much depends on the doors. For them are required three main requirements: sealing the steam room, resistance to heat, steam / water, a decent level of safety. Only doors that open outwards can be regarded as safe.

It is also important to use materials that do not heat up to dangerous levels. The design of the doors in the bath must be as simple as possible.

It is reasonable to use a leaf with a height of 1.7-1.8 m and a width of 0.6 to 0.75 m. Other sizes will be suitable only for design or other individual considerations. The classic option remains the use of wooden canvases, which successfully compete with more modern solutions. They also, purely psychologically, perfectly match the purpose of the steam room. Considerations for choosing wood species are the same as for wall finishing.

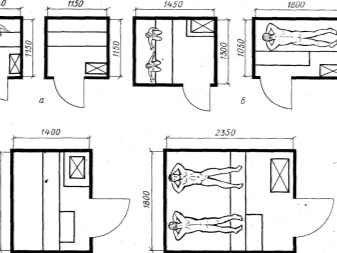

Making the shelves

To properly equip the sauna, it is necessary to provide and the presence of shelves. This piece of interior must be as comfortable and functional as possible. Decks are formed strictly of wood. Tiered structures are preferred, on which it is easy to choose the most suitable heat mode. Both in small and large steam rooms, bench shelves are used; a little less common are liezans.

Tips:

-

distance from the top to the ceiling at least 1.1 m;

-

seating width 0.3-0.4 m;

-

length according to the height of the tallest user;

-

distance from the stove for safety reasons;

-

no resinous types of wood should be used;

-

Use of only first quality material.

Recommendations

Sometimes resin drips in the steam room, and it's an unavoidable process. The easiest way to remove resin drips help solvents, but it is better to immediately choose a wood species that will not give such a risk. You can also treat the surface with a special cutter. As for the height of the steam room, it must correspond to the height of the tallest members of the family. Additionally take into account insulation and other materials.

A ceiling height of more than 2.4 m is not practical. Thinking about the size of the steam room, it is required to take into account the freedom of movement around the room. Thermal insulation of frame baths should be as perfect as possible. As for the shelves, usually use 2 or 3 tiers. A loose arrangement of boards with a gap of up to 0.01 m is allowed; high-quality sanding is mandatory.

How to finish the steam room with your own hands, see below.