Finishing of the steam room in the bath

Finishing the steam room - this is one of the most important stages of the construction of the bath. Therefore, it is necessary to treat responsibly both to the planning of the room, and to the choice of materials.

Features

All materials used when finishing the room of the steam room, must meet a number of criteria.

- Durability. First of all, they must be of high quality and protected against mold and mildew. This will make the room attractive in appearance and safe for recreation. In addition, all materials used should be durable. This will save money on the repair of the steam room.

- Sustainability. Since steam is an integral part of all bathing procedures, the materials should also be resistant to the effects of hot air.

- Eco-friendliness. It is unacceptable that the material in the process of heating emitted harmful chemicals. Therefore, for the finishing of the steam room, it is necessary to choose a suitable wood, as well as to carefully study the composition of all impregnations.

- Decorativeness. Since the steam room is a place for rest, it is necessary to make it as attractive and comfortable as possible. Therefore, it is worth paying attention to both the color and the texture of the materials.

Proper finishing of the steam room allows you to make the room not only comfortable and safe, but also comfortable.

What kind of wood is better to trim?

Most often, natural wood is used for finishing the inside of the room. Each type of wood has its own advantages and disadvantages.

- Lime. This material is good because it almost does not change under the influence of temperature and steam. Many people like linden because of the fact that it has a pleasant cream color. When heated, the wood fills the room with a pleasant aroma. But, unfortunately, it heats up very quickly. Therefore, a linden shelf before using it should either be covered with a sheet or doused with cold water.

- Alder. This material is also excellent for finishing rooms inside. Black alder pleases with its performance characteristics. Over time, the material almost does not change color and shape. In addition, it does not heat up at all. Therefore, resting in such a room, you can not be afraid to get a burn.

- Aspen. This material is also often used in the sauna or bath. It does not heat up at all and is an excellent insulator. The disadvantages of aspen are its appearance. Over time, the wood turns gray under the influence of moisture and deforms.

- Larch. This type of wood is of high quality and attractive appearance. Despite the low cost, larch serves for quite a long time. It is considered that in its quality it is not inferior to valuable species of wood with similar properties. The only disadvantage of this material is that this dense wood is difficult to process.

- Ash. This material costs more than the previous ones. Therefore, it is used for finishing steam rooms much less frequently. However, it is worth noting that small rooms decorated with wooden panels of ash look very beautiful. The wood is not afraid of the effects of high humidity and hot steam. It has healing properties. Therefore, spending time in such a steam room is especially useful for people with respiratory diseases.

- Oak. This type of wood is of high quality and density. It looks solid and stylish. This option of elite finishing is usually used for decorating small modern steam rooms. Its main disadvantage is its high cost. Special attention deserves African oak abasi wood. This finishing material has excellent resistance to humidity and hot air. In addition, it has a beautiful rich color.

- Birch. This material is ill-suited for finishing the steam room, as it is afraid of moisture. To decorate the room, it is worth using wood coated with special protective compositions. In this case, it will not go mouldy and rot over time.

- Cedar. Quality Canadian cedar is used to decorate steam rooms in elite baths. When heated, the wood exudes a pleasant aroma, filling the room with beneficial essential oils. In addition, Canadian cedar wood finishes look attractive and aesthetically pleasing.

When finishing the room of the steam room is not recommended to use conifers, such as pine or spruce. This happens because of the following points:

- The wood is strongly heated, and touching it can cause burns;

- Pine changes color over time to a darker color;

- In the process, the wood emits resins, which in contact with the skin can also burn it.

You should not cover the walls in the steam room with varnish or stain. In the process of heating the room, they will release harmful chemicals that adversely affect the human body.

What other materials can be used?

In addition to beams and logs, other materials can also be used for finishing the room. One of the most popular is stone. It is often used to decorate the area next to the stove. However, it is worth remembering that it heats up too much. You should also pay attention to some other materials.

- Serpentinite. This inexpensive material is very strong, safe and durable. The natural mineral is green in color with flecks of marble highlights looks very beautiful. In addition, serpentine has beneficial medicinal properties. Therefore, to rest in a steam room with a finish of such a stone is worth it for people who often experience headaches or suffer from colds.

- Talcochlorite. This stone is also popularly called bath or soap stone. It perfectly accumulates heat and gives it away evenly. This finish looks stylish and original. It is also durable and reliable. Over time, the stone does not burn out, does not melt and is not covered with cracks.

- Himalayan salt. Tiles of black or pink salt can be used to decorate the walls and ceiling in the steam room. This material can originally decorate the room for the rest, making it cozy.

- Porcelain stoneware. This material is resistant to steam and strong mechanical stress. It is safe and durable. Granite, as a rule, is used for finishing the floor and walls.

- Jadeite. Environmentally friendly material perfectly responds to temperature fluctuations and is not afraid of moisture. It is one of the most durable stones used for finishing baths and saunas.

- Quartzite. This fine-grained stone is very durable. You can choose to decorate the room materials in a variety of shades. This allows you to make a steam room stylish and beautiful.

When choosing materials for finishing the room, you should also pay attention to moisture-resistant gypsum board. It can be used for the construction of partitions. In some cases, drywall products are painted with moisture-resistant paint. But this option is short-lived.

You can also use tile or glass blocks to finish the space next to the stove. They do not last as long as uncut board or natural stone, but they look attractive.

Stages of finishing with your own hands

The process of finishing the steam room can be divided into several main stages. Simple instructions can help you understand where to start the work.

Floor

For finishing the floor in the steam room, wood is most often used. Before laying the boards, it is worth preparing for this process. On a sandy or concrete substrate, it is worth installing small brick pillars. On them, the joists are laid. To prevent them from rotting, they should be impregnated with antiseptic. On the installed joists are laid edged or tongue and groove boards.

To better retain heat, the floor is located at 15 centimeters higher than in the room for the rest.

Walls and ceiling

As a rule, the room is trying to finish in the same style. Therefore, For a room with wooden floors, it is best to choose a suitable finish for the walls. It is necessary to choose panels or linings made of quality wood. The material must be well dried and debarked.

Interior panelling your own hands begins with the preparation of the walls. The first thing to carefully caulk all the cracks and joints or fill them with installation foam. After this you need to fix the wall grid of slats. If the walls in the steam room are flat and smooth, this step can be skipped.

In some cases, the room is additionally insulated. For this purpose, you can use mineral insulation, which is placed directly under the crates.

After this, you can proceed to the process of finishing the bath. First it is necessary to choose the appropriate fasteners. They must be of high quality and well protected against heat and moisture.

Next, the batten should be cut into pieces of suitable size, and then neatly attached to the wall or lattice. Usually special staples are used for this purpose. If it is not possible to accurately trim the wall, the prepared pieces of wood should be slightly trimmed and sanded. Before you start paneling, the timber should be treated with a quality antiseptic.

The material that was used to decorate the walls, you can also use for decorating the ceiling in the steam room. Remember, this is where the highest temperature is kept.

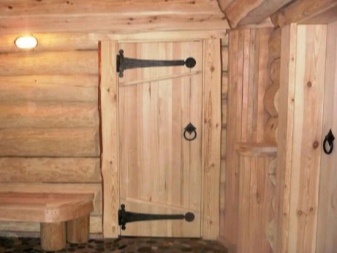

Doors and Windows

Doors and windows must be installed before wall cladding. This is done in order to always be able to close the mounting points and gaps between the walls and the box. If you miss this point, the cold will penetrate into the room.

Optimal materials for making doors to the steam room - tempered glass and heat-treated wood. They are highly durable and provide excellent thermal insulation. These doors also look very attractive.

The step-by-step process of their installation is very simple. The first thing is to prepare all the necessary materials. The design of modern doors consists of the following parts:

- wooden frame;

- handles and hinges of stainless steel materials;

- contour seal;

- glass holders.

Installation of the door begins with the installation of the door frame. Its position is aligned by the building level, and the gaps are filled with the usual assembly foam. When the box is installed, you can move on to the next stage of work. The door leaf is hung on the hinges.

During installation, it is worth remembering that the door in the steam room should open outward. After that, you can fix on it platbands and fittings.

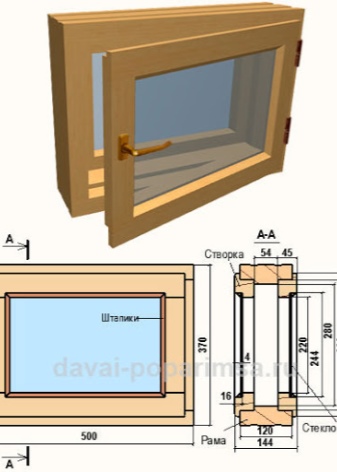

In a traditional Russian bathhouse, there should also be two windows. The first is the main one and is located directly in front of the door. Under it are the shelves. Such a window is needed in order to ventilate the room if necessary.

The second window is located under the ceiling. It is small and almost invisible. Such a window is needed to dry the shelves. If this is not done, over time, the wood in this area can be covered with mold or deformed. After all, it is under the ceiling that moisture usually accumulates.

According to the safety of the windows in the steam room must open inward. This should be taken into account when buying and installing them.

You can use dowels to install the windows. They allow you to most firmly fix the frame in the opening. The window installation process consists of several basic steps.

- First of all, it is necessary to make holes in the frame for fasteners. The distance between them should be within 200 mm.

- Further the frame is established in a window aperture. Using a level and mounting pads, it is aligned.

- On the walls, points are marked, in which later holes will be made for the sleeves of dowels.

- After that, the frame is removed to the side, and small holes are drilled in the selected points.

- Then dowels are inserted into them. The frame is returned back to the window opening. Nails are inserted into the sleeves of the dowels.

- Having finished with the fasteners, you can remove the pads from the frame, fill the gaps with assembly foam or natural finishing material. For this purpose, linen fiber or jute is well suited.

If everything is done correctly, the windows will be securely fixed and the owners of the bath will not encounter any problems during their operation.

Shelves

After finishing the finishing work, you can proceed to the installation of benches (shelves). They can have different sizes and appearance. The choice is influenced only by personal preferences and the financial capacity of the owners of the plot.

As a rule, they are made of the same wood that was used to finish the walls, floor and ceiling. The most beautiful look shelves with rounded ends. The benches are usually placed in front of the stove. This is done so that when people are resting, they cannot accidentally burn themselves by touching this unit.

It is also important to make sure that the distance between the top bench and the ceiling of the bath is appropriate. Usually it is within 1-1.2 meters. In this case, it will be comfortable to sit on the shelves. Metal elements, which are used for fastening, must necessarily be hidden. Otherwise, a person can get burned by touching hot metal.

After installing the benches in the room, you can place small footstools, consisting of wide boards, as well as caddies, washers and ushats. This will make the room more comfortable.

Examples of design

Features of the design of the steam room depends entirely on the wishes of the people who use it. When equipping such a room for recreation, you can for inspiration examples of ready-made interiors.

Room in the Russian style

Most often, when decorating the steam room, people are inspired by traditional Russian baths. Natural wood is used to finish the room. Brus are finished both the walls, and the floor and ceiling. The furniture in such a room is also bought wooden. Additionally they can be decorated with carvings.

Decorate the room and make it more comfortable, using various small things that remind of the Russian bathing culture.

Modern steam room

The room in the modern style looks very simple and stylish. For finishing the room, you can use both natural wood and stone. Instead of a massive stove in the corner there is a small fireplace. Additional lighting makes the room more comfortable. It will be comfortable to relax in it at any time of day.

To equip your home with a small steam room, you do not need to buy expensive exotic materials and spend a lot of money on services of specialists. Having studied all the information about finishing the steam room, you can make a budget repair in this room with your own hands.