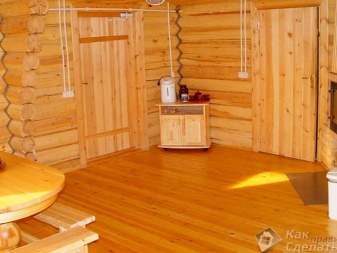

Floor treatment in a bath: basic means of protection against rot and fungus

Construction of sauna complexes is performed in stages. It is important not only to properly design the foundation and erect reliable walls, but also to take care of the arrangement of the floor.

Why do you need impregnation?

Flooring must be treated with special compounds to protect it from moisture and rot. In baths, where this recommendation is neglected, the floor rots quickly. Treatment is needed not only for wooden flooring, but also for concrete.

You can handle this work yourself, the main thing - to choose the right protective compositions and familiarize yourself with the technology of their application.

For the right choice of impregnation should take into account its purpose. Protective composition closes pores, stopping rot. Special impregnations protect the top coating and the substrate, for example, lagging. Impregnating compositions can be combined with other materials designed to treat floors.

The service life of floors impregnated with impregnation agents increases significantly. But this is not the only argument in favour of impregnations. In the treatment compositions there are coloring substances that emphasize the natural beauty of wood.

The use of such products significantly reduces the risk of rotting, but cannot completely eliminate it. The effectiveness of impregnation largely depends on the manufacturing company and the components present in the composition.

Main sorts and properties of impregnations

There are several types of impregnations for the floor, which are acceptable to use in bath rooms. The most popular are antiseptics against rotThey serve as a good prevention of fungus.

Impregnations for flooring are usually classified according to the purpose, according to this parameter allocate:

- compositions that prevent the penetration of moisture;

- antibacterial;

- Products that protect the wood from ignition;

- bleaching and dimming impregnations.

Means, created to protect against moisture, fill the pores of the wood and as they dry, they clog them. The reliability of such protection depends on the depth of penetration of the compound. This information is usually indicated on the container with the solution.

It is also important to keep in mind that not all products are suitable for a certain type of wood, when buying, you should always consult with the seller.

- All bathing sets need antibacterial protection. Increased humidity creates optimal conditions for intensive reproduction of pathogenic microflora. Such protection is required, first of all, for wood, because bacteria provoke its rotting.

- Fireproof compounds are not often used in baths, but it is a good solution for wood located near the stove. Means from this line form a layer impervious to fire, not only on the outside, but also in the pores of the wood. It is not possible to completely eliminate the risk of fire with them, so it is important to observe safety precautions.

- The blacking agents have a decorative function, but many of them contain components that protect the wood from moisture and bacteria. This series of products is used to give natural wood a certain shade.

- Bleaching compositions are used in cases where the wood, which is finished sauna, from time to time becomes dark. Among the owners of baths there are those who decide to completely replace the finish, before you do it is worth to use a bleaching agent. Usually they treat darkened spots, rather than the entire floor surface.

Surface treatment

The floor in the bath should be treated not only if it is made of wood. Impregnations are also used for concrete coatings, as well as for tiles.

Concrete

If a concrete floor is laid in the steam room or washing room, You need to cover it with a special compound. Impregnation will strengthen the new coating of concrete. With its help it is possible to restore and old floor, which has defects, and the restoration concerns not only the appearance, but also the characteristics.

The impregnation will significantly increase the level of durability: the floor in the steam room will become less susceptible to temperature fluctuations, exposure to moisture and mechanical damage.

Concrete flooring crumbles all the time, resulting in dust formation. Impregnation will solve this problem, it will bind small particles of building material.

Such a treatment will several times increase the life of the floor.

Untreated coating will constantly require repair, the use of a protective composition will save money.

To process the concrete floor involve compositions based on organic and preparations of inorganic origin. The first have an epoxy, acrylic or polyurethane basis. The most popular compositions, the main component of which is polyurethane. They can be purchased at a reasonable price and their performance characteristics are superior to their counterparts.

The applied product penetrates into the concrete pores, ensuring reliable bonding of the surface. The floor becomes waterproof, dust disappears.

Inorganic compositions are less in demand. Their action is very simple: thanks to them, soluble materials are transformed into insoluble ones. Thus increasing the resistance of the coating to different solvents.

Solutions for floors made of concrete, it is customary to divide into:

- reinforcing;

- eliminating dust;

- repelling moisture.

Means, having a reinforcing effect, soaking into the upper concrete layers, harden, the coating becomes less susceptible to mechanical stress.

Dusting compounds prevent the concrete surface from abrasion and make it more durable. Such a treatment is ideal for painting.

Moisture-repelling impregnation, affordable and has good protective parameters. It prevents the penetration of destructive microorganisms and chemicals into the concrete.

When selecting the impregnation, it is important to make sure that it is suitable for the grade of concrete, otherwise it will react chemically with it.

Before using a protective composition thoroughly Before using a curing compound thoroughly prepare the surface. Any irregularities can be removed with sandpaper. At the preparatory stage it is important to get rid of all cracks and voids. After leveling the concrete surface, remove debris, as an additional measure, you can vacuum the surface and go over it with a damp rag.

Finish with the preparation, apply the impregnator by roller or pour it on the floor, making sure it is evenly distributed. Act in accordance with the instructions, it is better to study them before you start. Pay attention to how long it takes for the first layer to dry.

Use a rake to remove excess impregnation.

Wood

In many baths, the floor is wooden, made of boards, it needs special protection.

In the first step Sand the surface with a special machine. You can also use sandpaper for this purpose, but it will take more time.

Use a vacuum cleaner or broom to remove wood dust. Then wipe the surface with a damp cloth.

Wait until the wood is completely dry in the wash room, then start the treatment.

It is most convenient to apply the product with a roller, and hard-to-reach areas should be treated with a brush.

Apply the protective composition in several layers, you can use different impregnations, for example, a combination of antibacterial and moisture protection. Maintain a time interval before applying each subsequent coat.

Tile

Tile itself does not need protection, the main thing is to choose a tile that is resistant to high temperatures and soapy substances. Preference should be given to rough textures to reduce slipping when wet.

Do not put tiles with glaze in the bath, they will quickly become cracked and have to be replaced.

Protective treatment requires joints. Over time, the grout is washed out, and moisture begins to penetrate under the tile, leading to fungus and mold.

To treat joints between tiles in the bath apply means on a polymeric and mineral basis. These are universal options, but it is better to use specialized compositions that clean and strengthen the grout.

Before treating the joints, rule out damage. Sometimes it is necessary to completely eliminate the old filling. This can be done by mechanical cleaning. After that, proceed to chemical treatment, drying and application of a protective agent.

Use masking tape to avoid damage to the tiles.

Recommendations

When treating the flooring in the sauna, do not forget about preventive measures:

- Ventilate rooms after each visit to the steam room;

- Clean rooms regularly to reduce the risk of unwanted microorganisms;

- Do not leave the sauna complex unheated for long periods of time.

- Do not use products designed to protect floors to treat wall surfaces and ceilings.

- Treat the flooring according to the instructions. Apply the product to a clean and dry surface.

- If you have a problem with insects, use alcohol-based products.

- Keep in mind that some formulations contain staining components that change the color of the wood.

- Try to treat the surface thoroughly, to impregnate all the cavities - this will avoid premature destruction of the floor.

About what to treat wood in the bath, see the following video.