All about the floors in the bath

Many owners of country houses build bathing facilities on the plots. When equipping such structures, special attention should be paid to the finish. For her, a variety of materials will be suitable, but they must all meet some important requirements. Today we will talk about what characteristics should have the flooring for the bath and how to choose the right material for it.

Requirements

When creating the project of the sauna room should also think carefully about the finish. Only certain materials that will meet the basic requirements will be suitable for the design of floors. Thus, the floors for the bath must have a minimum level of moisture absorption. A good basis will not absorb water, swell from a large amount of liquid.

Moisture-resistant materials are often additionally coated with protective agents to increase these characteristics. Untreated coatings will absorb water and deform. In addition, flooring for the bath must be as resistant to sharp temperature changes. The material should quickly ventilate and dry out. The level of durability also plays an important role.

Floors must also be resistant to possible mechanical damage.

Types

Nowadays, there are many materials that are suitable for finishing bath structures. Floors in such facilities can be made of the following bases.

Wooden .

It is from this material most often make the floor in baths. It is recommended to use coniferous and deciduous surfaces, including cedar, spruce, fir, larch or oak. Coniferous options are preferred because they are able to release resin, which contributes to a longer life span. At the same time, alder and larch have a higher wear resistance. The structure of these species is as dense as possible, so they do not absorb liquids. But the price of this wood will be much higher compared to conventional softwood boards.

Wooden coatings in baths can have healing properties on the human body. It will not deform when exposed to large amounts of water on such floors, in addition, it will not be slippery. Quality natural wood is characterized by easy installation technology, environmental friendliness, ease of cleaning, high level of durability. But many models belong to the expensive group of materials.

Wood also has some other disadvantages. Such a base needs special care, which will prevent the floors from rotting. Often they are covered with special chemical compositions, which do not allow the wood to lose its appearance and quality. Wooden floors for the bath, as a rule, assume a large consumption of materials during installation work. In addition, they are characterized by a long drying time, but it will also largely depend on the design features of the coating.

Wooden floors in the steam room and washing room can be of two types: leaking and nonleaking. The first option involves gaps between the panels. In this case, the water will flow freely through these spillage floors into these recesses. All the moisture will be absorbed into the ground layer, sometimes building special metal structures, by which it will be diverted to a separate place. But they need to be covered with special compounds, so that the metal will not rust. Leaky floors can be of the suspended type, in which case they are attached directly to the wall covering with special fixtures.

Non-spill flooring is a one-piece floor construction, which has no gaps. But such material is laid in such a way that it is at a slight angle.

At the lowest point of the non-penetrating surface yourself need to make a small hole, it is in this hole will drain all the moisture.

A solid wooden floor is most often constructed with thermal insulation material. This significantly reduces heat loss through the flooring. It is better to buy tongue and groove boards to create the flooring.

Concrete

Such floor surfaces are particularly durable and resistant to harmful effects of moisture. The service life of concrete is not less than 50 years. But at the same time, the material after laying will always be cold even in such rooms, so you can install special heating systems.

Concrete bases refer to the materials of the pouring type. This option is considered the most practical, because, in addition to resistance to moisture, it is resistant to mechanical damage, the flooring will not deform even after strong blows and loads.

Concrete is not prone to rot, so it does not need special treatment, unlike wood. But the base has several significant disadvantages, among which we can highlight the complex technology of installation, as well as significant monetary costs. In addition, it is not distinguished by a beautiful appearance. Often, when decorating the room, it is covered with another finishing coat.

These floors for the bath most often after drying and sanding are covered with ceramic tiles with a special anti-slip coating. You can also use for this purpose and structures consisting of wooden grids or slabs of wood cork. Also for baths sometimes take particleboard. Such boards belong to the material of the new generation. These sheets have a high level of moisture resistance, durability, hardness and strength.

Cement-bonded particleboard is an environmentally friendly material. Mineralization technology is used in the manufacturing process, so there is no emission of harmful substances in the operation of the floors. Cement-bonded particleboards are panels composed of pressed components, so they, like conventional concrete, do not have a beautiful appearance, so they are covered with finishing decorative surfaces (ceramics, mosaics), resulting in a double coating. Sometimes these boards are used as a base for another material.

Ceramic

Ceramic flooring used for bath structures is most often coated with protective anti-slip compounds. Ceramic boasts excellent moisture resistance, but this property applies only to fine-pored models. Also, ceramic bases should have a slightly rough surface, this will provide maximum traction with a person's foot on a wet floor.

In addition, the tiles have good wear resistance and resistance to significant loads, mechanical effects, strong possible impacts.

When finishing floors, you should only use ceramic tiles from the same batch. Products from different sets can spoil the appearance of the building. Cladding with ceramic tiles requires a special installation technique. Before laying the material, it is necessary to carry out a number of preparatory construction measures, including making a screed and installing a cement-bonded particle board.

Ceramic base for the bath has a special durability, it is not afraid of sharp temperature fluctuations. The tiles will not require special care, they can be cleaned with ordinary detergents and a sponge. Ceramics is considered a durable material that is not afraid of accidental mechanical damage, chemicals. Such a base is made of clay and special mineral additives. These components are safe for humans, they are environmentally friendly.

Bulk

These floor coverings are gaining in popularity among consumers. They are beginning to replace stone and ceramic models. After all, they have a beautiful appearance. Also, the poured types are more durable.

Poured floors are a polymer mass evenly distributed on the base. They boast a high level of wear resistance, strength, hardness. In addition, the surfaces are completely fireproof, they do not emit harmful substances to humans.

Poured models are easy to clean. It can be done with any detergent compositions. Samples have an interesting design, they assume a large variety of different decorative images. Often such floors are made under an individual order.

But poured coatings have some significant disadvantages. They include too long installation time. It takes several days for the polymer mass to fully cure. In addition, the cost of flooring will be much higher compared to the other types.

The installation of the coating will be quite complicated not only by the long drying time. It will require more careful sealing in the joints between the floors and the walls. Particular attention should be paid to creating a base for the floor. Most often wood is used for this purpose.

Along with the wood under the floor should be built concrete reinforced screed of great thickness.

Pouring should be carried out as quickly as possible, as it quickly loses its fluidity, it will be unevenly distributed over the surface, the work will have to redo.

Before pouring, it is necessary to accurately determine its level. It is marked on the wall covering in the bath. Marks should be made along the entire perimeter. Full load on the floor can be given a week after the pouring.

Sometimes plastic models are also installed in baths. But most often it is a plastic board made of thermoplastic wood composite material. Such coating is installed at the entrances to the structure or in places where the impact of water and low temperature in the room will be the least. Such plastic can be installed in the bathing rooms of the sauna, for the Russian sauna, it is better not to use such a variant.

Unusual option will be and the floor of natural or artificial stone. Stone tiles have a beautiful appearance. Today, products of serpentine, talcochlorite, pyroxenite are produced. Such varieties have good strength, hardness and durability. But the cost of such coatings will be much higher compared to concrete, wooden bases.

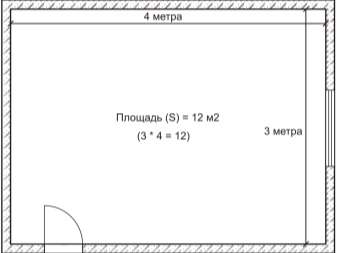

How to calculate the material?

When you decide on the material for finishing in the bath, you need to correctly calculate how much of it will be needed for installation. To do this First, make accurate calculations of the area of the room, separately the width and length. Then correlate the obtained dimensions with the dimensions of the material. This takes into account the thickness of the joints and the height of the walls. Also take into account additional materials, including insulation.

To calculate the number of insulation products, the total floor area is taken into account. If necessary, you can cut panels for insulation. The thickness of the boards also plays an important role. If the base together with these materials has a significant height, then the finishing elements are better to choose a relatively small thickness, so as not to take too much away from the height of the walls and not to reduce the space in the room.

If you purchased a ceramic tile with a pattern for the bath, then in this case you need to pay special attention to the calculation of the material. Such models are almost impossible to trim a little, it can spoil the appearance of the base. When installing wooden planks, you should consider their thickness to correlate with the logs.

So, if the thickness is 25 mm, then the step between the beams will be 40 cm, if it is 40 mm, then the step will reach 60 or 70 cm.

How to choose?

In advance, you should decide on the type of material for finishing the sauna room. The traditional option will be different types of wood covering. In this case, the wood is treated so that it becomes moisture-resistant and resistant to low temperatures. Such structures have a relatively low cost.

If you have chosen a wooden model, then you should take care of a structure that will ensure water drainage. In other bases, as a rule, make a small hole into which all the liquid goes. Under the wooden floors, you can build a structure on which all the moisture will flow into the ground or to be diverted into the container provided.

Such devices should be made of durable materials that are resistant to corrosion. Periodically, such devices will need to be checked, if they break, all the liquid will remain in the bath or drain to another inappropriate place. For washing rooms and steam rooms, a concrete base with a removable wooden flooring on top would be a good option.

Tiles, made of natural or artificial stone, will make the floor covering as strong as possible and resistant even to significant loads. But the cost of this material will be much higher compared to the previous option. The most original solution will be coating with ceramic tiles or poured floor. These types have a beautiful and interesting design, they are often decorated with decorative drawings.

If you are equipping a sauna, then the best option will be a reinforced concrete structure. This is due to the fact that in every sauna is placed a swimming pool, it is almost impossible to make it out of wood, so they use such materials. Recently, swimming pools made of high quality and durable plastic with a special treatment are gaining in popularity. In this case, the floor covering can be made of different types of wood.If your bath provides a room for recreation, then it is possible to pick up almost any material, and it does not necessarily have to be waterproof. But it is still better to give preference to heat-resistant bases. When choosing a material, remember that some coatings are installed together with heating. First of all, this applies to concrete floors.

After pouring and hardening, they become cold, even in baths, so before installing them in the room provide heating systems.

It is worth remembering that, heating structures can take away a lot of height in the room. But Today, special modern floor heating systems are available. They are easy to install with your own hands, they will not take up too much space, but, as a rule, and the price of them is higher.

How to make?

Let's consider the technology of installing wooden coverings in the bath. First, you need to form a fat layer of clay on the ground under the floor, which is thick enough, and the surface should be at a small slope to the place where the liquid will flow down and go to the special filtering installations. In the process of roughing it is possible to use cement screed instead of clay. The water pit can be additionally equipped with a water trap. You can also dig a pit with a drainage ditch, its surface is later filled with crushed stone.

After laying on the basis of asbestos-cement pipes, and then construct a wooden cover itself. In this case, it is better to build a solid floor. To make it as well ventilated as possible, you can install the sauna heater in such a way that the air inlet of such equipment is located underneath it.

You should start laying near one of the walls. In this case, a gap is made, leaving about 7-10 millimeters. This hole is created in order to compensate for the expansion of the material under the influence of large amounts of moisture and low temperature conditions. Mounting is performed with the tongue towards the wall covering.

Laying the second wooden board, its groove is carefully inserted into the tongue of the first board. In doing so, wedges are placed between the second board and the batten, with the help of which the boards can press against each other more tightly. This construction, if necessary, can be easily dismantled, all the work will be carried out in the same sequence.

If you are going to install a concrete pavement, then you must first build a solid base, which should be paved with gravel. On top lay additional elements that make up the construction "pie". They include the following components:

- waterproofing layer and ;

- vapor barrier and heat insulation;

- polystyrene foam;

- cement screed with a mesh of Rabitz chain-link;

- leveling layer.

Such a base will make the future coating durable and solid.

It is not uncommon to make concrete floors over a pole or strip foundation. Glass or plastic bottles can be used as insulation. They should cover the base under the floor. They provide an air layer, and the thermal conductive properties of air currents at the same time are worse than those of conventional solids.

Before pouring the concrete install trapezes, as well as pipes designed to divert moisture. The liquid material is then poured onto the surface and gradually distributed evenly. After a few days, the concrete will fully harden.

About how you can make floors in the bath, see the following video.