Features of cinder block baths

Many materials are offered for the construction of baths. Wood is considered traditional. Wood makes for environmentally friendly and aesthetic buildings. However, in recent years, other building materials are gaining popularity. One of them is cinder blocks. Before proceeding to the step-by-step construction of the bath, it is necessary to study in detail the features of this material, its main advantages and disadvantages.

Pros and cons

Slag-block baths have a mass of indisputable advantages, thanks to which every year the mineral blocks are increasingly popular. Such building materials are made on the basis of cement, sand, water and slag. They have different sizes, can be monolithic or have a cavity inside.

Consider the main advantages of such material.

- Inexpensive, but also fast construction of structures. Blocks have a favorable cost, since they are produced from the waste of the construction industry. They are lightweight, due to which the construction does not require hiring expensive special equipment.

- Resistance to fire. Cinder block - non-combustible material. This distinguishes it from natural wood. This property is especially important when building structures with high fire risks.

- Good thermal insulation. According to these indicators cinder blocks are slightly inferior to natural wood, but superior to brick.

- Excellent hygiene. Such a building material prevents the formation of mold, various types of fungi. Insects and rodents will not be caught in it.

Baths, made of cinder block, are considered durable structures. Regardless of climatic conditions, they can last at least 100 years.

Cinder blocks are not a perfect building material. It has significant disadvantages, with which you need to familiarize yourself before starting work. For example, if you choose large corpulent blocks, you will have to lay a reinforced foundation.

Cinder block is hygroscopic, which means that it can absorb moisture in large quantities. In addition, the material is strong, which often makes it difficult for builders to make holes for laying communications.

The described blocks are not distinguished aesthetic appearance, which is why the sauna built of them will need interior and exterior decoration. This will require additional labor and financial costs.

Projects

Before you build a bath, it is important to perform a series of measures: to choose the site for the proposed structure and decide on the project. It can make it up independently, choose a ready-made solution, given as an example in this article, or order the development through a specialized company.

There are a huge number of cinder block bath projects. They vary in size, number of floors, layout, number and purpose of rooms. If the size of the site is limited by space, it is recommended to take a closer look at the projects of baths with two floors. In this way you can most effectively use every available meter.

If the family is small, preference is often given to small-sized structures. These may be bathing boxes with an area of 3x3 or 4x4 meters. It is worth taking into account that the number of people resting in the bath may increase over time. Because of this, it is recommended to look closely at the projects with a reserve area.

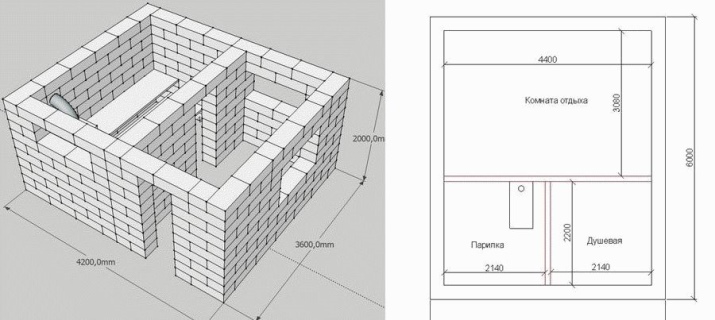

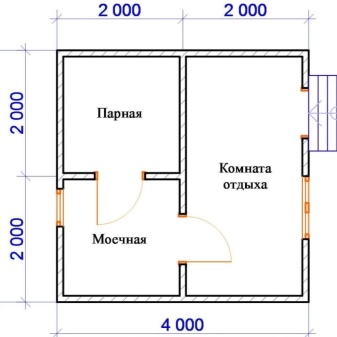

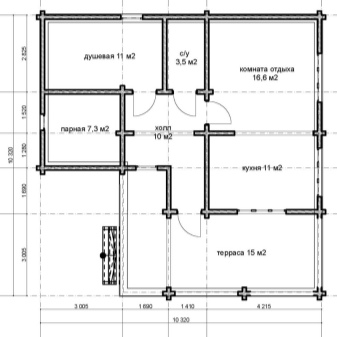

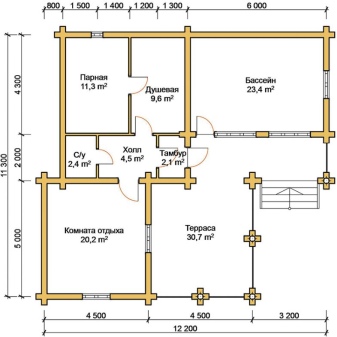

Keep in mind that Any project should include a steam room, washing area and room for rest. Not superfluous will be and vestibule - it will prevent the occurrence of drafts, as well as useful for storing various household items and utensils. Larger plans may include a tank for bathing, veranda, terrace, bathroom. Below are the projects of mini-bath, rooms with a swimming pool and a terrace.

In the presented schemes the rooms, their sizes, location of window and door openings are marked. Guided by the project, you can calculate the approximate amount of building materials and make an estimate.

Construction phases

It is possible to build a bath from cinder block with your own hands. All work is divided into several stages, which should be considered in more detail.

Erection of the foundation

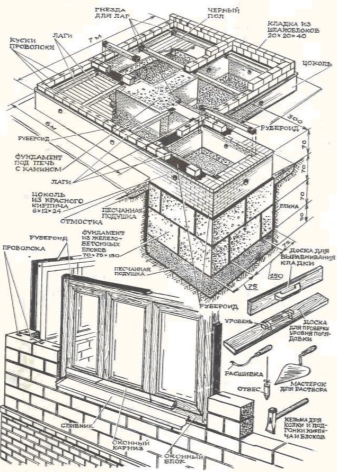

The foundation base is selected depending on the type of mineral blocks used. For example, for lightweight hollow material, a columnar foundation will be suitable, and for full-body - monolithic. For the erection of a columnar foundation, pegs are taken and placed in the corners of the future bath, cords are stretched between them. Next, holes are made along the perimeter and in areas where the walls intersect. The distance should not exceed 1.5 m.

To install the monolithic base, it will be necessary to dig trenches and make a cushion of gravel and sand. The next step includes the construction of timber formwork (its height should not be less than half a meter). Then the reinforcement frame is installed, and then the formwork is poured with concrete mortar. When the concrete dries, the formwork is dismantled.

Please note: Due to the high hygroscopic nature of mineral blocks, the foundation is erected at a height of at least half a meter relative to the ground.

Masonry walls

The laying of walls made of mineral blocks is carried out by analogy with the brickwork. The work should begin with the installation of 2 cinder blocks in one of the corners (it is important to make sure that it is located strictly at right angles). After that, lay out the remaining 3 corners and the entire first row.

The following block line is laid with an offset. At the same time, the concrete mixture should be applied to the vertical and horizontal sides of the cinder block. Experienced builders advise using a mesh of reinforcement in masonry (install it in every 3rd row). This will make the construction more reliable and durable.

When masonry must leave areas for window and door openings (according to the project documentation). On top, do not forget to make a slab of timber. Hollow cinder blocks are not suitable for laying the perimeter of the windows. Only monolithic blocks are used for this purpose.

Insulation

Bath boxes made of mineral blocks are quite cold, because of which such structures need to be properly insulated. To do this Wall surfaces from the outside are coated with primer, and the joints are grouted with a plastering mixture.

To insulate the walls from the inside, the joints are also grouted, after which a frame slatted wooden base is mounted. For this purpose, larch, aspen or spruce treated with oil-based moisture-protective compositions will be suitable.

For maximum insulation of the wooden battens are sewn on the foam board, and then you need to install counter-battens. It is fixed mineral wool and insulation material.

Construction of the roof

The basis of the roof - wooden beams, the diameter of which should not be less than 10 cm. They are laid on the erected walls. Depending on the project, the roofs can be with one or two slopes. One-slope variations are more simple in execution. Often they are chosen in the construction of small-scale structures.

Choosing a gable roof, there is an opportunity to equip as an attic zone, and attic. For its installation will need to install a rafter system, and on it - the roof. Popular roofing materials are slate and roofing felt, and of the modern - ondulin.

Finishing options

A mud-brick bath without additional finishing looks unaesthetic. To improve the thermal insulation and decorative qualities of the structure, it should be clad. When conducting cladding work, various finishing materials are used.

Interior

To finish the walls and ceiling inside the steam room or rest room, most often use cladding. It is an environmentally friendly building material that does not emit harmful substances when heated. It has excellent performance qualities: resistant to moisture, mechanical stress, easily withstands temperature extremes without deformation. Cladding is reliable and durable. For the conditions of the sauna is best to use finishing materials from aspen or alder.

For finishing the recreation area you can use tongue and groove boards. When tiling the floor use both natural wood and ceramic non-glossy anti-slip tiles. By the way, tiles can often be found in baths, where the exit from the steam room leads directly to the room for rest.

To finish the bathroom or washroom, ceramic tiles, mosaic or plastic panels are used. For tiling the floor surface with tiles is better to buy ribbed materials, the surface of which is slip-resistant.

Exterior

Exterior finishing is an important and obligatory stage in the construction of a cinder block bath. External cladding work is necessary to add aesthetics to the structure, as well as to protect cinder blocks from various adverse external factors. If you neglect the external finishing, the mineral blocks can soon collapse.

For finishing work manufacturers offer a wide variety of materials. Baths are often clad with siding. On the market there is a wide range of colors of such trim, so the buyer should not have any problems in choosing the best palette. Due to the huge selection of colors you can easily make the sauna room interesting and original.

Decorative plaster for facade work, brick, artificial stone or tiles for building facades are also suitable for finishing. Choose finishing materials should be in accordance with your taste preferences and financial capabilities.

Examples of prefabricated baths

It is easy to build a mud-bath by your own hands in a short time. Its construction is inexpensive. It is a great option for a family holiday or a get-together with friends. Such baths look original and elegant. The examples below allow you to visually verify this.

On how to properly lay a wall of cinder block, see the following video.