Plans and construction of saunas with profiled beams

Building a bathhouse made of wood is a long tradition in Russia. Russians have been steaming in such baths for many hundreds of years. The smell of resin in the bath has a beneficial effect on well-being. New woodworking technologies have emerged, allowing us to observe the traditions in the construction of baths, and at the same time use new materials, not just simple cylindrical logs. Structures of profiled beams are built in summer houses, homesteads.

Features

Build a sauna from profiled bar easier and faster than from other materials. The price of construction by 10-15% less than that of bricks, cinder blocks. Bath is collected as a construction set. Professionals can assemble a log cabin for 15 days. To build a building without flaws, you need to know the peculiarities of the construction of wood products.

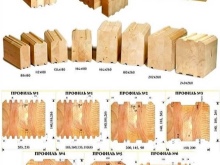

Profiled timber is a modern type of lumber produced industrially. This is a parallelepiped-shaped log with different section sizes. Standard sizes according to GOST:

- The length of the product - 3-6 m;

- The thickness and width - 100*200 mm, the minimum section - 140*90, 140*140;

- The width of the timber can be made with a cross-section of 300 mm upon individual order.

The sides of the finished timber are flat or rounded, and there are tongue and groove notches at the bottom and top of the timber. The tongue and groove joints come in many shapes. The so-called Finnish joint has two tongue and groove. There is a place for insulation inside. Bar cross-section is 140*190. German connection or "comb" consists of five nips and grooves. Bar section is 200*200 mm. In this connection, the tongue and groove are firmly fitted to each other.

Bar is made from pine, cedar, aspen, larch, spruce. The most popular wooden profile made of pine. Its main advantage - it is cheaper than others. Products made of spruce, pine exude resin, so you need internal finishing battens. For the construction of the bath is best suited beam made of lime, cedar and aspen. Spruce timber has a more aesthetic appearance and is used for internal partitions.

It is recommended that the bottom basement rows be made of oak or larch logs. This is the strongest and most durable wood material that does not rot for a long time.

There are two types of profiled bar: solid and laminated. Solid woodblock is sawn in a sawmill from the center of the log. The wood is the hardest. Glued beam is assembled and profiled from several identical parts dried in the chamber, assembled into a single log. Insulation is put between the parts. Parts of the beam are securely glued to each other. But it is less environmentally friendly because of the chemical composition of the glue. Its length is up to 12 m.

After production, all timbers are treated with antiseptic to protect against fungus. The most reliable timber, which subsequently will not crack, made from wood harvested in winter. Companies engaged in construction, prepare wood and erect logs, as a rule, it is in this period. This is due to the fact that the wood contains less moisture in winter. Baths built in the winter give less shrinkage compared to summer buildings.

An important indicator of the quality of profiled beams - its moisture content. There are two types according to this indicator:

- timber of natural moisture;

- Product chamber drying.

Natural humidity of wood - 18-23%. If you build a sauna in the summer out of a bar with such humidity, later under the influence of sunlight in the timber formed cracks, which freely fits the palm. Therefore, from a damp log house built in early winter, so that the moisture evaporated by the beginning of finishing. Sauna, built from a log of natural moisture, subsequently gives the shrinkage of 10-15%. Profiled bar after chamber drying has a moisture content of 12-18%. Chamber-dried bar is expensive, but durable. After the construction of dry profiled beams for shrinkage is 1-4%.

When stored in a set does not change shape, does not deform the spikes and grooves of the profile.

Pros and cons

What kind of timber to use in the construction of the bath depends on many factors. If the object will be built in winter, it is not worth spending money on chamber-dried timber, you can use wet timber. Over the winter and summer excess condensate will evaporate, and you can proceed to the finish. In the other case it is better to use dry timber. During the construction of the bath use a bar with a section of 150 * 150 to 200 * 200 mm.

Profiled bar, like any other material, has advantages and disadvantages. The advantages are undeniable:

- eco-friendly wood material, except for glued wood;

- the speed of assembly, the rapid erection of the bath;

- small labor costs;

- economy of construction, you do not need the cost of finishing the facade;

- a bath made of wood "breathes", that is, the walls freely ventilated, there is a pleasant smell of wood;

- joint "tongue and groove" provides tightness of the building.

Buildings made of profiled bar in the process of construction and operation revealed flaws:

- The timber of natural moisture cracks in the sun;

- wood rots from moisture;

- buildings made of wood are fire-hazardous compared to others;

- the price of dry timber is high.

If you follow the rules of construction, you can successfully level out these unpleasant factors:

- to build a bathhouse of dry timber;

- use larch or oak timber for the first rows of a log cabin;

- Build a brick plinth;

- to treat the facade with varnish or paint;

- fill cracks with elastic sealant;

- to treat against fire with flame retardant;

- Protect from fungus treatment with antiseptic.

The bath does not need a strong foundation. The foundation can be strip foundation, post foundation or shallow foundation. Ribbon foundations or shallow foundations are created for large and medium-sized baths.

Projects

In order to keep the bathhouse warm and not turn into a cold damp room, you need to choose a plan and a project that is appropriate to the location, time and financial capabilities of the owners of the building. Baths are built on standard or individual projects. The size of the bath depends on the size of the site, the number of people who will be in the bath at the same time, the price of the construction.

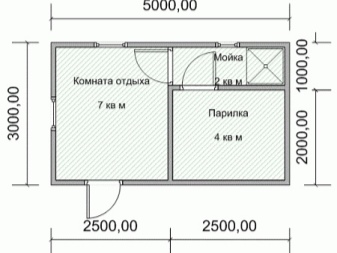

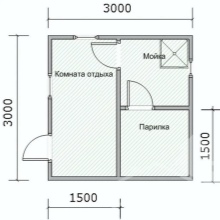

Recommended per person 1.5-2 square meters in the steam room and 2-3 square meters in the rest room. When the size of the bath is defined, a drawing is made. The number and size of the rooms is marked on the drawing. The location of windows, interior doors, the central entrance are marked. Provide locations of sewage and ventilation.

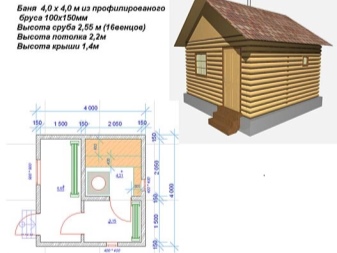

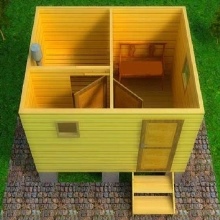

Small

For a small bath, the economy project is provided. It is a bathhouse with one steam room and a pre-bath. The size of such a bath - 3 * 3 meters. The steam room occupies 5 square meters and the anteroom 4 square meters. For a small bathhouse, sometimes a single-pitch roof is built. For such baths, in some cases, no porch is built, only steps with a small canopy. Small baths include buildings with dimensions of 5*3 m. Here you can place three rooms: a steam room, a washing room and a rest room.

The steam room is combined with the washing room, which is rather uncomfortable. But the rest room measuring 7 square meters can accommodate 3 people. This project does not include a pre-bath. In winter such a bathhouse will cool down quickly, but it is very convenient for summer use. You can increase the area by placing an attic on top of the building, in which case it will serve as a recreation room. The lower part of the building can be reconstructed by placing a separate washing room or a pre-bath.

Sauna with a loft is a good option for a small plot.

Medium

In bathhouses with dimensions of 6*4 m, 6*6 m and the number and area of rooms is larger. Sauna 6*4 is the best option for the site. It does not take a lot of space and at the same time allows you to place the necessary rooms in this area. A bathroom can be provided in such a bathhouse, which is very important when a small group or family visits the bathhouse. The size of the rooms is determined by the customer. But we must take into account that it is undesirable to equip the steam room of more than 6 square meters. In a large steam room it is difficult to create the right temperature, it will take a long time to heat up.

In the medium-sized baths at the request of the customer provide an open terrace under the roof. The area of medium-sized baths allows you to make it in the plan of the bath. Projects with terraces are popular. They are created for comfort and relaxation after bathing. If you glaze the terrace, you get a bath with a full veranda.

Large

If the size of the land plot allows, then the baths are built with the size of 8*8 m, 10*10 m. They look like full houses with a double pitch roof, veranda, a large number of rooms. Such projects include playrooms, guest rooms, large recreation rooms, and a bathroom is mandatory. On the veranda you can install an oven or other devices for cooking. Of course, such buildings are more expensive than small or medium-sized baths.

If the structure is two-storey, on the second floor an attic with living rooms is placed. The lower floor is built of 200x200 mm timber, while the upper floor is made of thinner timber. As a rule, swimming pools are placed in front of large baths.

Construction details

When building with profiled bar, it is necessary to take into account that the sun is the enemy of wood. Therefore, you should choose a place so that the front of the terrace faces the sunny side, which will protect one of the walls from the sun's rays. It is necessary to observe some rules in the process of construction.

- If you build a small bath, the foundation for it are screw piles with height compensators, which level the structure after shrinkage. If time permits, the log cabin is left to shrink before finishing. A 150*150 mm log cabin will take 6-18 months to shrink.

- Lower wreaths, the plinth perform a bar soaked in creazote. Bitumen mastic applied in two layers at the junction between the plinth and the first row of beams. Sometimes the lower wreaths are covered with a fine mesh against rodents. For waterproofing and ventilation performed socle air holes.

- Rejected timber with cracks, darkened lumber. Use it for auxiliary purposes.

- As a heater should use jute, linen, moss. There are artificial fibers that do not rot unlike natural materials.

- Use wooden dowels to connect the logs.

- To check the moisture content, use a handheld moisture meter, so as not to be deceived when buying the material.

- Corner joints require special attention. There are two types of joints: a joint with a remainder and a "warm corner". It looks nice with the remainder, but requires more material consumption. The interventional corners are insulated with hollofiber.

- It is obligatory to make compensatory cuts in the ends of the log. They prevent the inner part of the log from cracking.

- Floor joists are sawn at the base of the building. Installation of the rough floor is carried out from the bottom of the edged boards. Floor in the recreation room is performed from tongue and groove boards, and in the washing room - from a board with a gap for water drainage.

- Partitions are mounted from a bar section of 100 * 100 mm or 100 * 120 mm. On them are applied with staples foil-isol for waterproofing. And then they are covered with clapboard. Between insulation and battens leave a free space for ventilation.

- The roof is covered with ondulin.

It is very convenient to buy prefabricated sets of baths or house sets of beams. Construction of such buildings is carried out in a short time. The kit contains numbered parts. Assembly is performed according to the schemes. Notches are provided for windows and doors. Kits include corner joints ready to install.

Review reviews

The construction of baths made of profiled beams has been underway for many years. Therefore, a lot of reviews of the owners of these baths has accumulated. After several years of using the bath, the main reviews are:

- there is no need to insulate the sauna, except for the floor;

- for two hours the steam room heats up to 80 °;

- low consumption of wood if the furnace is brick;

- For the average strip of Russia is quite sufficient size of timber 160 * 190 mm;

- The owners note the speed of construction of prefabricated houses - from 5 days to several weeks;

- Economy on the outside trim - no need to decorate the facade;

- interior decoration is necessary for baths made of pine or spruce beam - resin drips from the walls and ceiling;

- quite controversial statement of some owners that the thickness of the bar does not affect the speed of heating the bath.

Other users do not see the point of saving money and building on their own, if you do not understand the issue. They give advice - to entrust the construction to professionals. Contradictory reviews leave about the baths made of glued beam.

Some owners of baths made of this material do not see any harm from the fact that there are harmful substances in the bar, do not feel the smell. Ecology connoisseurs do not advise building from it.

Beautiful examples

- Average bath from a bar with a facade, tinted with colored varnish, looks like a full-fledged house. The foundation is lined with decorative stone. Corners are decorated with finishing material of contrasting colors. The originality of the construction gives a bay window, which is a recreation room. The terrace is decorated with openwork walls and flowers.

- In a beautiful bathhouse, the interior decoration should also be at a good level. For example, a designer has worked on the finishing of this steam room. All elements are in harmony. The semicircular shelves match the fan ceiling. The furnace design with openwork bricks echoes the ceramic tile floor finish. The bright lighting makes it feel like the hot sun.

In the following video you will find a detailed review of the profiled bar bath.