A foam block bath

For many years, bathhouses have been erected from wood. This material is well suited for such a task, but it is quite expensive. Penoblocks - a modern solution that allows you to significantly reduce material costs and speed up the construction process.

Pros and cons

Like many other materials, foam blocks have their own specific pros and cons. The advantages are many.

- Good insulating qualities and frost resistance. In terms of properties, a foam block bath is much like a similar structure from a log cabin. Microporous structure provides good air circulation, the structure breathes, reduces the likelihood of fungus and rot.

- Low flammability. For safety, it is better to use this kind of material. It can for a long period of time to withstand the effects of high temperature and not ignite. Low flammability index - the main requirement for the choice of all materials used in the construction of the bath.

- Large volume and small weight greatly simplifies the construction work. Due to the porous structure, bulk blocks are relatively light and strong. Therefore, problems with transportation, lifting to a height, as a rule, do not arise.

- If you analyze the cost of materials, foam block beats many alternatives in this regard.

- The special structure provides increased strength. Therefore, the structure will stand for a long time, it can take a serious long-term load.

- Construction work can be carried out independently even in the absence of any skills. Such a material is easy to handle, this does not require expensive special tools.

Another feature is that the construction practically does not give shrinkage, it will be possible to use almost immediately after the erection and completion of finishing work. There are also a few significant disadvantages to consider.

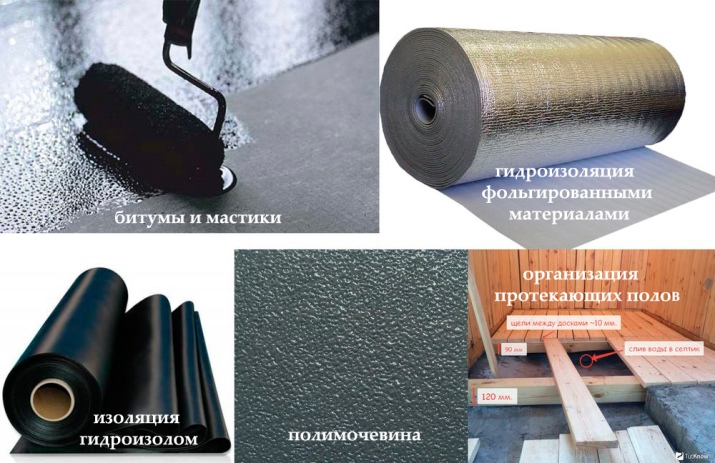

- The main disadvantage is related to the porous structure, which determines the low resistance to moisture. You have to do quality insulation, otherwise during the operation of the construction there will be unpleasant moments.

- The accumulated moisture can cause cracks in the block structure when the ambient temperature drops in winter. Too many defects will reduce the bearing capacity of the structure.

- The material should not be used for the construction of tall buildings. This is due to the fact that the porous structure is unable to withstand high pressure.

- If you do not carry out special finishing and surface treatment, there is a probability of fungus and mold.

In terms of environmental friendliness, foam block is inferior to wood. Therefore, it is necessary to consider all the pros and cons when planning construction.

Projects

The work should begin with the creation of a project. It is necessary to take into account the recommendations on the calculation.

- Various layouts can be found on the Internet, with drawings and detailed plans often attached. Some of them can be downloaded for free, others are sold. After receiving the documents, they need to be carefully studied, to consider all the features.

- The next step is to calculate the required amount of material. This will eliminate the possibility of unplanned stoppages. Pre-calculation will allow you to determine the costs at the time of design.

- All calculations should be made with a 10% margin, especially if the work is carried out independently without experience.

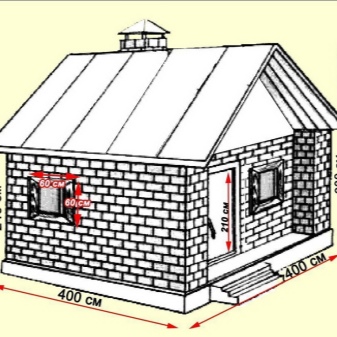

The most important parameter by which to choose the project is size. A small bath will cost less, and there will be fewer problems with the construction. However, if you calculate the required area incorrectly, with the reception of bathing procedures can be difficult.

A modern bathhouse can resemble an ordinary house or an outbuilding. The construction must be not just beautiful, but also meet all the requirements. The height of the building is chosen taking into account that if the ceiling is too high, it will be difficult to heat the room.

Cheap you can build a sauna from foam blocks using conventional insulation materials. However, modern offerings that cost more will provide better conditions.

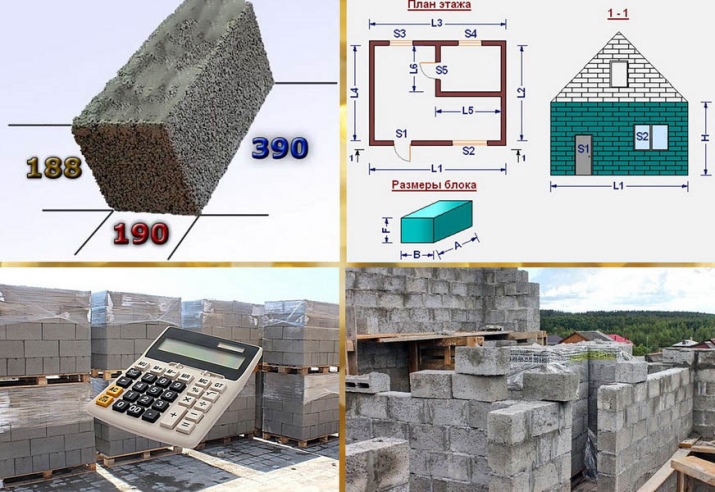

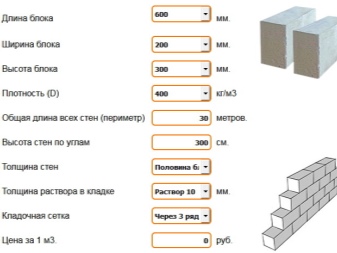

Calculating the amount of material

After choosing a suitable project, it is necessary to carry out the calculation of the required amount of materials. This can be done using special online calculators or manually. After obtaining the result, you need to add another 10% for reserve.

To calculate the number of blocks, it is sufficient to know the area of the walls, as well as their thickness. After that, the required amount is determined taking into account the size of the blocks. You can often calculate the number of foam blocks on the seller's website.

Step by step construction instruction

If you carry out the construction step by step, you can reduce the likelihood of making a mistake. To begin with, it is necessary to prepare the required tools and materials:

- River sand will be needed to create a sand cushion under the foundation, cement or adhesive mixture;

- cement is considered the most common component used in the creation of adhesive compositions;

- reinforcing tube can be used to reinforce the foundation or the main box, it is better to give preference to chrome-plated versions;

- wire is used to connect the individual elements of the structure;

- sewer pipes will be required in the case of creating a drainage system designed to remove excess moisture from the site;

- self-tapping screws and nails are considered indispensable connecting materials, variants of different lengths and diameters will be required;

- corners made of durable metal are used to strengthen the structure;

- windows can be different, in recent times are often installed plastic, but you can also use wood;

- bricks are often used to build load-bearing structures, which have a heavy load;

- doors must have high thermal insulation qualities, handles must be made of material that will not heat;

- waterproofing is designed to protect the main materials from the effects of increased moisture;

- insulation allows to reduce the cost of heating;

- finishing materials are chosen based on personal preferences, the allocated budget for construction, the requirements for finishing

- lighting should be designed for installation in a room with high humidity;

- wires must have good insulation, resistant to high temperature;

- antiseptic agents are designed to protect surfaces from the formation of fungus;

- building foam is considered the ideal modern material for sealing small joints, cracks and gaps.

Each step can be carried out separately, but it is highly recommended not to leave the foam blocks without protection for a long time, as they can quickly absorb moisture. The scheme of construction is as follows.

- Preparation of the site involves the removal of all large stones and debriswhich could interfere with further work. Often performed the lifting of the top layer of soil. If a drainage system will be created, additional work on site preparation is carried out.

- Erection of the foundation is recommended to perform at low humidity and high enough ambient temperature. You can create any type of foundation, for example, strip or pile.

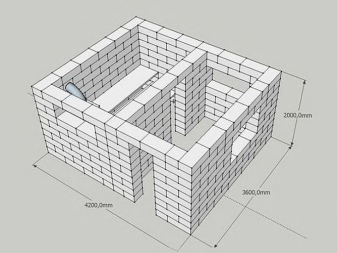

- The masonry walls, as a rule, are carried out in several stages. This work will require the blocks themselves, a level, a trowel, and a string to level a row.

- Laying of interfloor floors Is often performed when using wood.

- Erection of the roof is complicated by the fact that you have to lift the materials to a height.

- Installing insulation does not take much time. There are quite a few modern fasteners on sale, which simplify installation.

- Finishing is complicated by the fact that the work must be carried out carefully to preserve the attractive appearance of the room. It is recommended that before direct selection of materials to familiarize themselves with various examples of their application.

With their own hands you can do almost everything. It is important to build the foundation correctly - it must have the required load-bearing properties, as well as have protection from the environment.

Foundation

The considered basic material is very light, so problems with the creation of the foundation, as a rule, do not arise. Most often, the project involves the creation of a strip structure. It is used in conjunction with a sand cushion, which is responsible for the even distribution of the load. There are certain recommendations for creating a foundation.

- A strip-shaped hole is dug all around the perimeter. When doing this work, it should be ensured that the edges are flat. If the work will be divided into several stages, it is recommended to additionally strengthen the walls that are formed. Heavy rain can erode the trenches, and the work will have to be done again.

- The height of the ditch should be 600 mm, the thickness - 300 mm. This is quite enough to create a load-bearing foundation for a one-story structure.

- Next, the marking is performed. For this purpose, pegs are often used, which are hammered into the perimeter, and a rope is stretched between them.

- The bars are installed along the entire perimeter every 2 m. They will act as a kind of marker for the level of pouring the cement composition.

- The formwork should hold the concrete, it is laid around the perimeter and fixed. In its creation a solid wood with a smooth surface is used. After the created ditch is filled, strong pressure will be exerted on the restraining structure. Spacers are placed around the perimeter of the structure.

- To save cement composition, large stones can be used. They are placed evenly, closer to the center.

- Pouring the formwork can be divided into several stages. The main thing is that the mortar should not be too liquid. Each layer is carefully tamped.After pouring, the surface is covered with a special mesh. It is recommended to cover the surface with waterproofing material to prevent the likelihood of precipitation. For solidification of the mortar is given about 1 day, for the set of full strength will take about 5 days.

The last step is waterproofing. After that, it will take time for the construction to gain strength.

Walls

After the concrete has dried completely, you can proceed to the construction of the walls. The masonry is carried out in rows. Features of this stage:

- the highest corner of the building, for which the building level is used;

- the first row is the most important, the quality of the entire masonry depends on it; the bottom row is laid on the cement base, it has higher load-bearing capacity in comparison with other adhesives;

- after the completion of the lower tier the surface is leveled, all defects are corrected;

- the accuracy of the location of all blocks is checked with a construction level, too serious differences can lead to the fact that the next rows will fall down;

- The last row is laid using a special glue that is ideal for this task.

When erecting walls, the blocks are laid in staggered order. Rarely, but may come across elements with defects that should not be used.

Interfloor ceilings

Often a project with an attic or an attic is used. In this case, an interfloor floor is laid. It is often created when using lumber.

The installation of the bar is carried out after careful treatment of the surface with various protective agents. They significantly increase the service life of the natural material.

The roof

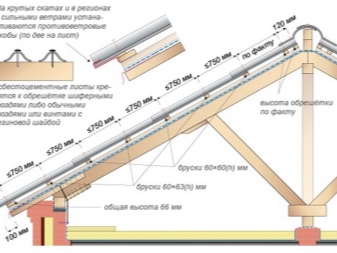

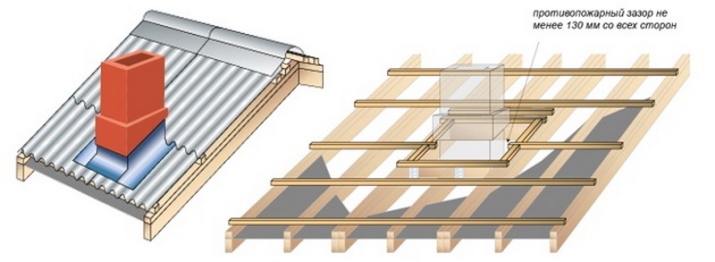

With the construction of the roof should not be delayed, as precipitation causes an increase in humidity. Difficulties may arise with this stage, so at least one helper will be needed. Recommendations for the construction of the roof are as follows:

- rafters are formed for the canopy and decking;

- the recommended step for purlins is 30 cm;

- The recommended distance between the rafters of about 10 cm.

Obligatorily created ventilation in the ceiling. Also take into account the fact that you will need a place for the furnace pipe outlet.

Thermal insulation

After the construction or installation of the furnace is carried out thermal insulation of the room. Many inexperienced builders pay little attention to this stagebut it is the quality of thermal insulation of the room that determines the coziness and comfort in the bath, the amount of materials that will be used to heat the air and maintain the desired temperature.

Installation is carried out depending on the type of insulation material selected. The cheapest option is foam plastic, which is attached to the battens. There are also modern materials that can be applied by spraying.

Finishing

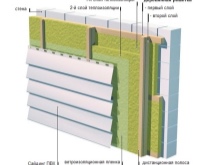

First, it is necessary to perform exterior finishing, which will provide the necessary protection of the blocks from high humidity and temperature fluctuations, after which it is possible to finish the structure inside. At this stage, additional insulation is also performed. The cheapest and most practical option is to create purlins and finish with siding. This work can be divided into several stages.

- Creation of a supporting frame. For this purpose, a bar is suitable, which is attached to the foam blocks with dowels. Bars are pre-treated with a special antiseptic, and then fastened to each other with screws to create a mesh structure.

- The resulting voids must be filled with insulating material. Outside is often used glass wool, which is inexpensive and can last for a long period.

- The surface is clad with the selected material. Screws of corrosion-resistant material are often used for fastening.

It is possible to cover the outside of the structure yourself. This step should also be given due attention, because moisture should not get under the cladding. Too high humidity causes the appearance of mold and mildew.

As a finishing interior material is used siding or natural wood. The most important criterion in the choice - the structure should not contain toxic substances, as when heated, they will be released into the environment. Fastening is carried out using different methods, all depending on the type of material selected

Interior decoration is often the final stage. After it is done, you need to wait some time and test heat the room. At this stage, you need to be careful, as there is a slight possibility of fire.

Reviews

Foam blocks began to be used for the construction of baths relatively recently, but many have used this material in the creation of such a structure. Feedback from owners say that after 10 years of operation of the bath, the construction perfectly copes with its task.

Baths of foam blocks - a more favorable solution than the construction of other materials. The erected structure can serve for a long period and perfectly copes with the retention of warm air and high humidity. If you follow all the recommendations, you can build such a sauna on your own very quickly. In this case, it is put into operation almost immediately after completion of work, which is an important plus. However, it is necessary to arrange a good ventilation and waterproofing.

About how to build a sauna from foam blocks, see the following video.